Fig. 10 — belt-drive motor mounting, Start-up, Heating (if accessory heater is installed) — to – Carrier 50LJ008-014 User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

#

t

To change fan speed;

1. Shut off unit power supply.

2. Loosen belt by loosening fan motor mounting plate nuts

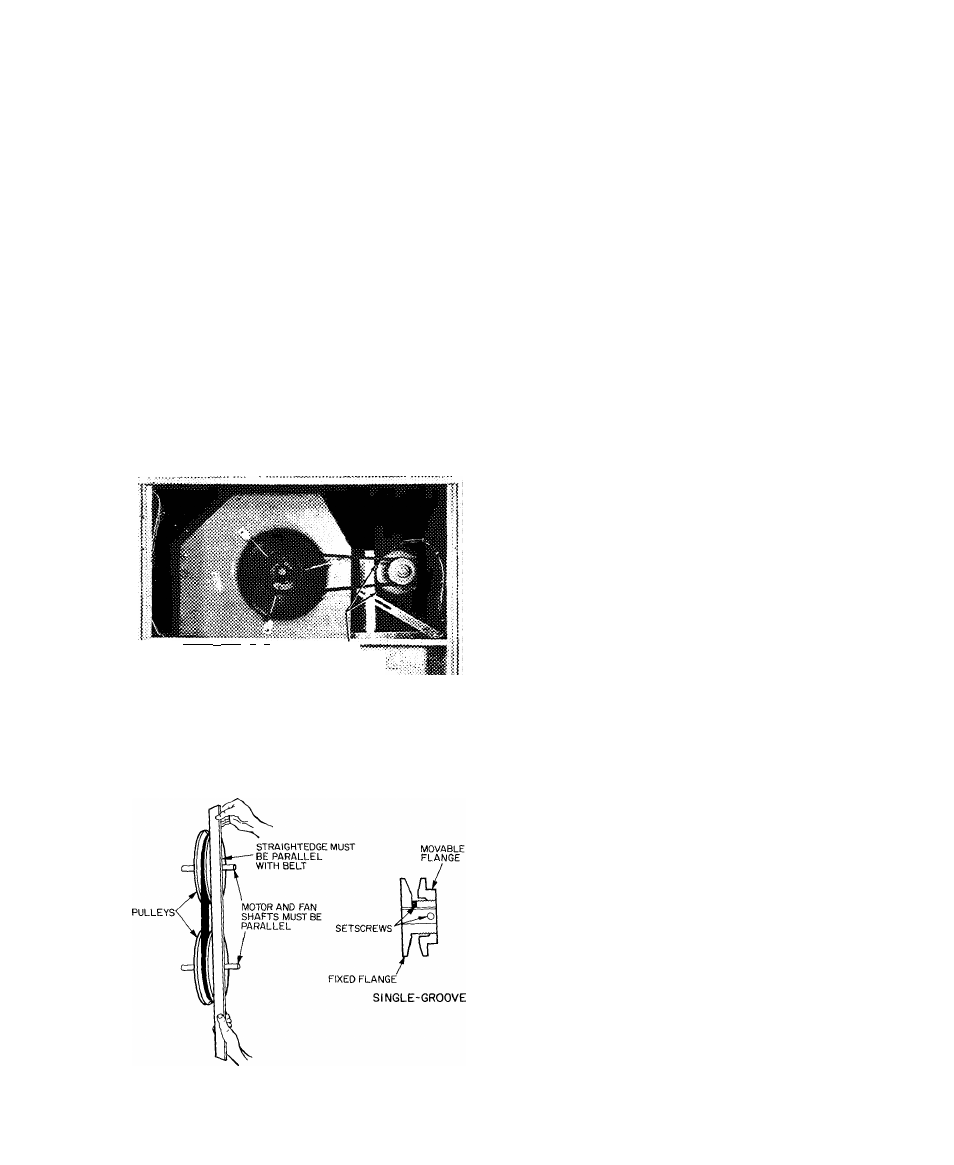

(see Fig. 10).

3. Loosen movable pulley flange setscrew (see Fig 11)

4. Screw movable flange toward fixed flange to increase

speed and away from fixed flange to decrease speed. In

creasing fan speed increases load on motor. Do not ex

ceed maximum speed specified in Table 1.

5. Set movable flange at nearest key way of pulley hub and

tighten setscrew (see Table 1 for speed change for each

full turn of pulley flange).

To align fan and motor pulleys;

1. Loosen fan pulley setscrews.

2. Slide fan pulley along fan shaft

3 Make angular alignment by loosening motor from mount

ing plate.

To adjust belt tension (see Fig. 10);

1, Loosen fan motor mounting nuts.

2. Slide motor mounting plate away from fan scroll for proper

belt tension (Vi-in. deflection with one finger) and tighten

mounting nuts. Tension can be applied using ‘/

2

-in. drive

—..........

1 1

—r r ?_i: f.i

"

MOTOR

.™Jli

Fig. 10 — Belt-Drive Motor Mounting

ratchet engaged into ‘/

2

-in. square hole on motor mount

ing plate.

3. Adjust bolt and nut on mounting plate to secure motor

in fixed position.

START-UP

IMPORTANT; Energize crankcase heaters 24 hours

prior to base unit start-up to remove entrapped refrig

erant from oil. Heaters are energized as long as there

is power to unit.

Fig. 11 — Evaporator-Fan Pulley Adjustment

Unit Preparation — Make sure that unit has been in

stalled in accordance with these installation instructions and

applicable codes.

Return-Air Filters — Make sure correct filters are in

stalled in unit (see Table 1). Do not operate unit without

return-air filters.

Compressor Mounting — Compressors are inter

nally spring mounted. Do not loosen or remove compressor

holddown bolts.

Internal Wiring — Check all electrical connections in

unit control boxes; tighten as required

Refrigerant Service Ports — Each refrigerant sys

tem has 3 Schrader-type service gage ports; one on the suc

tion line, one on the liquid line and one on the compressor

discharge line. Be sure that caps on the ports are tight.

Cooling — To start unit, turn on main power supply.

Set system selector switch at COOL position and fan switch

at AUTO, position. Adjust thermostat to a setting below

room temperature. Compressor starts on closure of

contactor.

Check unit charge. Refer to Refrigerant Charge section

on page 17.

Reset thermostat at a position above room temperature.

Compressor will shut off.

TO SHUT OFF UNIT — Set system selector switch at OFF

position Resetting thermostat at a position above room tem

perature shuts unit off temporarily until space temperature

exceeds thermostat setting.

Heating (If Accessory Heater is Installed) — To

start unit, turn on main power supply.

Set thermostat at HEAT position and a setting above room

temperature, and set fan at AUTO, position.

First stage of thermostat energizes the first-stage electric

heater; second stage energizes second-stage electric heater

elements if installed. Check heating effects at air supply

grille(s)

If unit does not energize, reset limit switch (located on

evaporator-fan scroll) by pressing button located between

terminals on the switch.

TO SHUT OFF UNIT — Set system selector switch at OFF

position. Resetting heating selector lever below room tem

perature will shut unit off temporarily until space tempera

ture falls below thermostat setting

Safety Relief — A soft solder joint in the suction line

at the low-pressure service port provides pressure relief un

der abnormal temperature and pressure conditions.

Ventilation (Continuous Fan) — Set fan and sys

tem selector switches at ON and OFF positions, respec

tively. Evaporator fan operates continuously to provide air

circulation.

15