Lubrication, Condenser-fan adjustment (fig. 15) – Carrier 50LJ008-014 User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

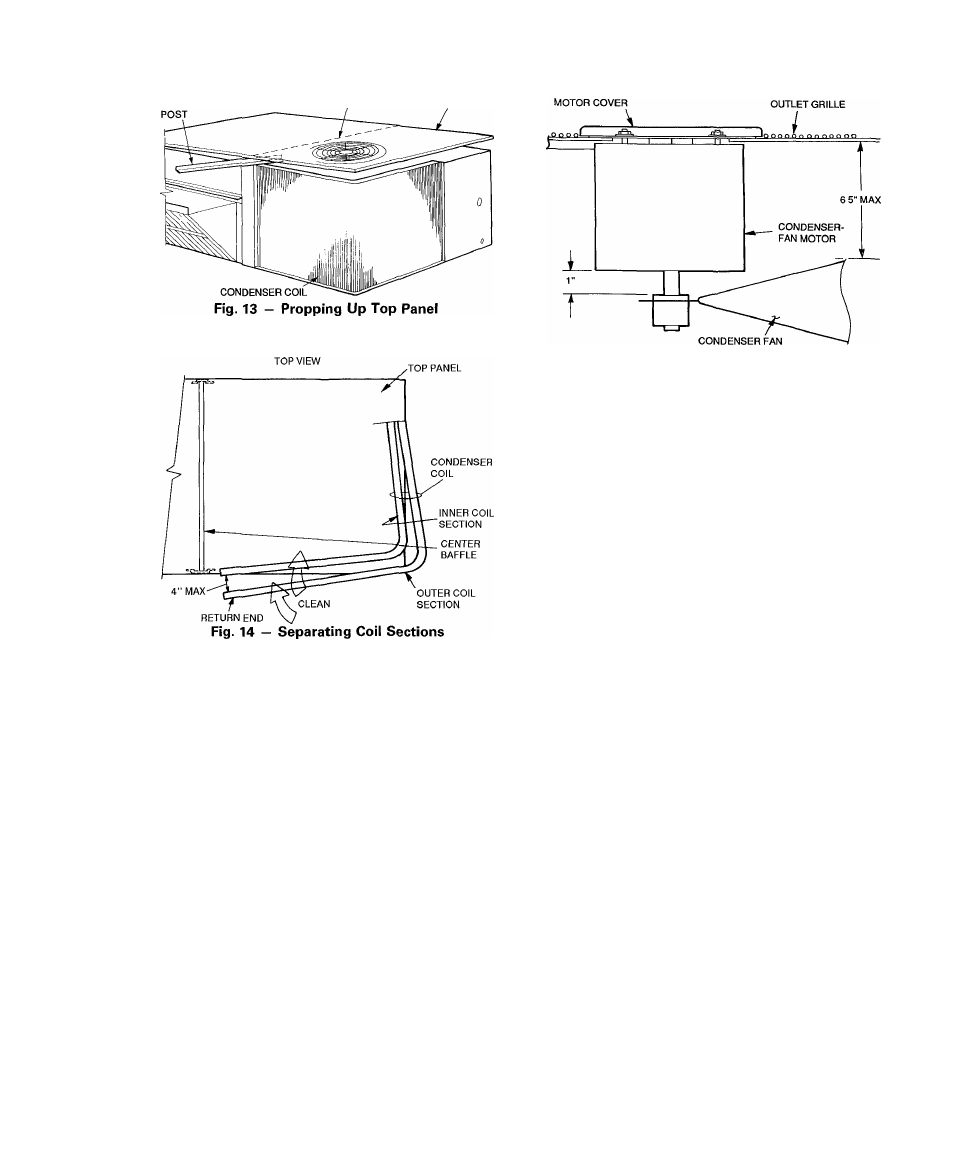

COIL CORNER

CENTER BAFFLE

TOP PANEL

6. Reposition the outer coil section and remove the coil

corner post between the top panel and center post. Se

cure the sections together. Install the coil comer post

and coil center post, and replace all screws.

CONDENSATE DRAIN — Check and clean each year at

start of cooling season. In winter, keep drain dry or protect

against freeze-up.

FILTERS — Clean or replace at start of each heating and

cooling season, or more often if operating conditions re

quire it. Replacement filters must be same dimensions as

original filters.

Lubrication

COMPRESSORS — Each compressor is charged with cor

rect amount of oil at the factory.

FAN-MOTOR BEARINGS — Fan-motor bearings are of

the permanently lubricated type. No further lubrication is

required. No lubrication of condenser- or evaporator-fan

motors is required.

Condenser-Fan Adjustment (Fig. 15)

1. Shut off unit power supply.

2. Remove condenser-fan assembly (grille, motor, motor

cover and fan) and loosen fan hub setscrews.

3. Adjust fan height as shown in Eig. 15.

4. Tighten setscrews.

5. Replace condenser-fan assembly.

Fig. 15 — Condenser-Fan Adjustment

Refrigerant Charge — Amount of refrigerant charge

is listed on unit nameplate (also refer to Table 1). Refer to

Carrier Standard Service Techniques Manual, Chapter 1,

Refrigerants section.

Unit panels must be in place when unit is operating dur

ing charging procedure.

NO CHARGE — Use standard evacuating techniques. Af

ter evacuating system, weigh in the specified amount of re

frigerant (refer to Table 1).

LOW CHARGE COOLING — Use Cooling Charging Charts,

Fig. 16-19. Vary refrigerant until the conditions of the ap

propriate chart are met. Note the charging charts are differ

ent from type normally used. Charts are based on charging

the units to the correct superheat for the various operating

conditions. Accurate pressure gage and temperature sens

ing device are required. Connect the pressure gage to the

service port on the suction line. Mount the temperature sens

ing device on the suction line and insulate it so that outdoor

ambient temperature does not affect the reading. Indoor-air

cfm must be within the normal operating range of the unit.

TO USE COOLING CHARGING CHARTS - Take the

outdoor ambient temperature and read the suction pressure

gage. Refer to appropriate chart to determine what suction

temperature should be. If suction temperature is high, add

refrigerant. If suction temperature is low, carefully blow

some of the charge. Recheck the suction pressure as charge

is adjusted.

Example: (Fig. 16)

Outdoor Temperature.........................................................85 F

Suction Pressure............................................................70 psig

Suction Temperature should be......................................... 42 F

(Suction Temperature may vary ±5° F.)

If Chargemaster® charging device is used, temperature

and pressure readings must be accomplished using the charg

ing charts.

17