Carrier 38GS User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Low-Pressure Switch

is located on unit suction line

and resets automatically. Low-pressure switch set

tings are: cutout, 3 1 + 4 psig; cut-in, 60 (+ 15, - 0)

psig.

High-Pressure Switch

is located on unit liquid line

and resets automatically. High pressurestat settings

are; cutout, 425 ± 5 psig; cut-in, 320 ± 20 psig.

Crankcase Heater

warms compressor crankcase.

Prevents refrigerant dilution of oil in crankcase.

Outdoor Fan Thermostat

maintains proper con

densing temperature at high outdoor temperatures

by switching fan to high speed. Located in control

box (on 38CE).

Filter-Drier

is installed in liquid line.

Time Guard® Circuit

provides for a 5-minute delay

before restarting compressor after shutdown for

any reason. On normal start-up the Time Guard

timer causes a delay of 15 seconds after thermostat

closes before compressor will start. On compressor

shutdown, the timer recycles for 4 minutes, 45

seconds. During this time the compressor cannot

start.

Solid State Time Delay

provides for a 4-minute

delay before restarting compressor after shutdown

for any reason. On normal start-up, timer is

energized after thermostat closes and causes a

4-minute delay before compressor will start.

Compressor Protectibn Control System

(CPCS —

Solid State) provides; compressor motor locked

rotor protection; compressor start winding pro

tection; compressor motor running overload pro

tection; compressor overtemperature protection;

contactor antichatter protection.

The CPCS also provides for a 4- to 6-minute

delay before restarting compressor after shutdown

for any reason. I f compressor loading was light at

the moment compressor was shut off, the delay

will be approximately 4 minutes. If loading was

heavy, the delay will be approximately 6 minutes.

To troubleshoot the CPCS, use unit label diagram

or wiring booklet and the following Control Circuit

Troubleshooting Chart.

CONTROL

CIRCUIT

TROUBLESHOOTING

CHART NOTES:

CAUTiON: Iks

nmt

i>ece|siacle fiHscomsctsd fr«i

ebm*

will up CICS

1. Ensure thermostat calls for cooling before

troubleshooting unit.

3.

4.

5.

6

.

2. To disconnect plug from receptacle on CPCS

board — press in tabs located on the receptacle

and pull plug gently while holding tabs. Do not

pull on wiring.

When performing troubleshooting checks, CPCS

receptacle must be plugged into CPCS board.

Receptacle female connections, which do not

grip the male pin tightly, may be repaired with

a small pen knife.

When taking meter readings at CPCS receptacle,

bottom meter probe into terminal hole to

ensure good electrical contact.

Replace CPCS board if electrical short circuit

causes compressor failure. An electrical short in

compressor can short the triac (electronic

switch located on CPCS board). Triac may fail

in a closed (conducting) position and will not

open the control circuit.

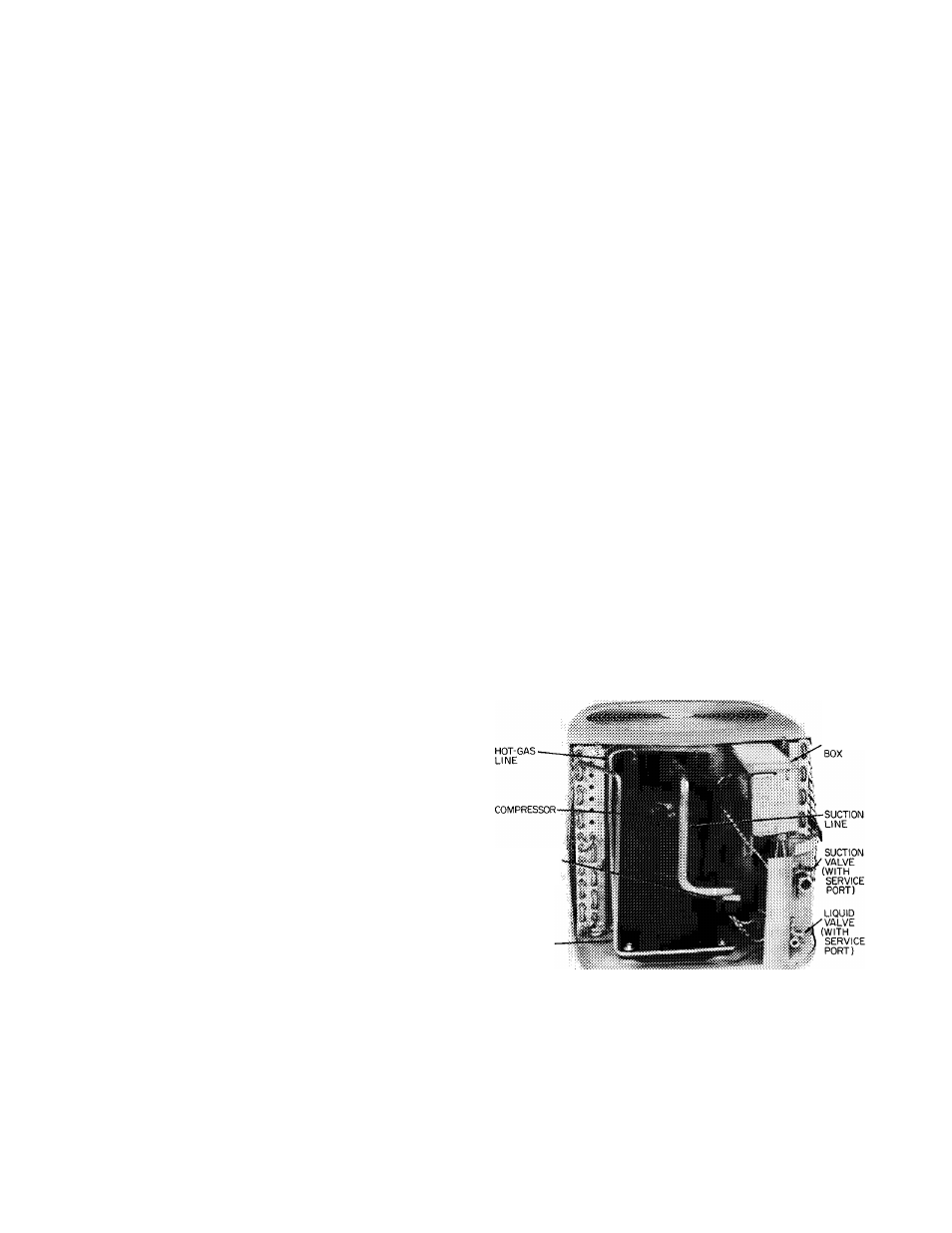

Compressor Removal

(See Table 7 for compressor

information and Fig. 5 for component location.)

1. Shut off power to unit. Vent refrigerant to

atmosphere or use refrigerant removal methods

shown in Carrier Standard Service Techniques

Manual, Chapter 1.

Remove top access cover and rear access wrap

per (Fig. 5).

Remove power leads from compressor terminal

box. Unsweat suction and hot gas lines.

Remove compressor hold-down bolts. Lift

compressor out thru top or back of unit.

2

.

3.

4.

CONTROL

COMPRESSOR

TERMINAL

BOX

LIQUID LINE

Fig. 5 — Condensing Unit with Access

Panels Removed

(38CE Unit Shown)