Carrier 38GS User Manual

Air-cooled condensing units

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Number One

Airconditioning

Mater

Syracuse New York

Air-Cooled Condensing Units

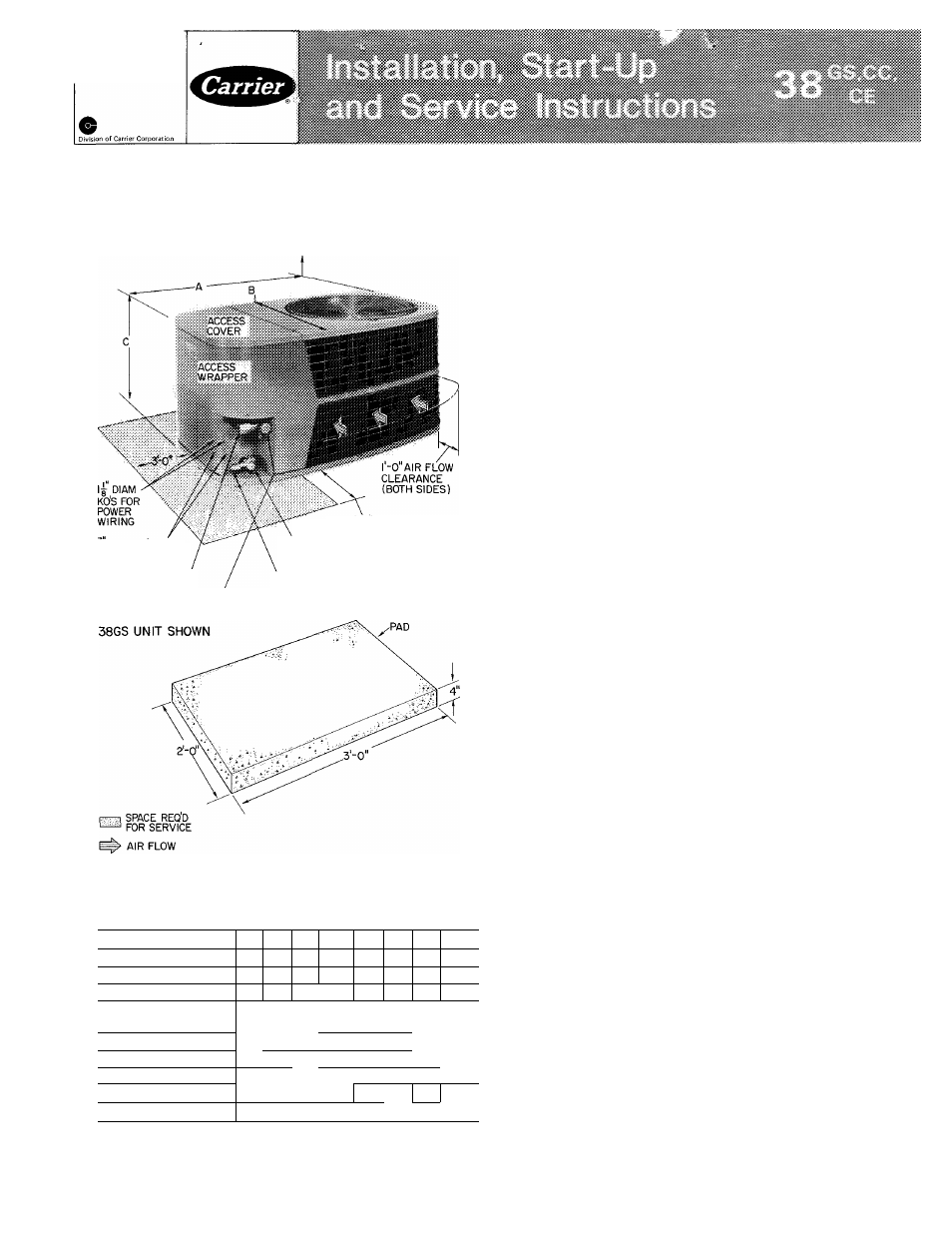

4'-0" OVERHEAD SPACE REQ'D

FOR SERVICE AND AIR FLOW

g DIAM KOS FOR

CONTROL WIRING

SUCTION LINE CONN

3 -0 (BOTH SIDES)

LIQUID LINE VALVE

LIQUID LINE CONN

SUCTION LINE

VALVE

CONCRETE

MOUNTING

Fig. 1 — Dimensions, Connections and Mounting Pad

38GS,CC,CE Unit

Table 1 — Installation Data

38GS

014 018 024 030

036 042 048 060t

COND UNIT 38CC

-

-

-

030

036 042 048 060t

38CB

-

-

-

002*

003 004 045 005

OPER WT (lb)

130

135

142|149

158

191

193

200

UNIT DIM. (ft-in.)

Length A

2-10V4

---- -----

Width B

'l-4

1-10

Height G

1-4

N4

Com

1-4 1 1-4 (2-0

2-0

2-0

REFRIG CONN.(in.)

DOtibl

e Fittings

Suction (ODF)

%

l Y s T

'/

b

I

%

'/4t

Liquid (ODF)

'8

*5/8-in suction connection on 38CE002

t38CE045,005 and 38GS.CC060 are factory supplied with 3/4- to

1

1/8-in

suction

valve

adapter

(field

installed)

for

1

1/8-in

suction line

TRANSPORTATION DAMAGE

File claim with shipping company if shipment is

damaged or incomplete.

Unpackaging Unit

— Move condensing unit to final

location. Open carton at end marked “compressor

end.” Slide unit from carton taking special care to

not damage service valves or grilles.

PRELIMINARY SURVEY

Consult local building codes and National

Electrical Code (NEC) for special installation

requirements.

When installing unit, allow sufficient space for

air flow clearance, wiring, refrigerant piping and

servicing unit. Position unit so water from roof or

eaves does not flow directly on top of unit.

Install unit on a solid, level mounting pad. Unit

can be attached to pad with a mastic adhesive or

by drilling holes in base pan for 1/4-in. mounting

bolts. Do not block base pan water drainage holes.

38GS,CC,CE

Condensing

Units

Connected to

Carrier Matched Evaporators with Carrier Acces

sory Tubing

— Check system refrigerant charge

when tubing lengths are above or below 25 feet.

See Refrigerant Charging (page 10) for details.

38GS,CC,CE Condensing Units Connected to Non-

Carrier Evaporators

— Check refrigerant charge

when condensing unit is added to a system in

which other than a Carrier approved evaporator is

being used or where the evaporator has been

previously installed. Field-supplied refrigerant pip

ing must be in accordance with Field-Supplied

Piping Data, Table 3.

Where indicated on Table 3 for 38GS,CE units,

install a liquid line filter-drier and accessory crank

case heater on condensing unit. (Filter-drier is

factory supplied on CE045,005 units.) Accessory

start capacitor and relay also required on 38GS

units, but not normally required on 38CE units.

See Compressor Service (page 7). All above items

are standard or not required for 38CC units.

Use an evaporator coil with a bleed-type ex

pansion device. If coil does not have a bleed-type

expansion device it may be necessary to add an

accessory start capacitor and relay to condensing

unit. This would require removing compressor start

thermistor (PTC device) on units so equipped.

© Carrier Corporation 1975

Form 38GS-13SI

Document Outline

- Number One

- Airconditioning

- Mater

- Air-Cooled Condensing Units

- Fig. 1 — Dimensions, Connections and Mounting Pad 38GS,CC,CE Unit

- TRANSPORTATION DAMAGE

- PRELIMINARY SURVEY

- PIPING CONNECTIONS

- ELECTRICAL DATA AND WIRING

- of ifolt ois tmpro|>er Ime

- Install a Branch Circuit Fused Disconnect of

- Fig. 4 -- Control Circuit Connections

- START-UP INSTRUCTIONS

- Start Procedure

- COMPRESSOR SERVICE

- UNIT PROTECTION

- CONTROL CIRCUIT TROUBLESHOOTING CHART (GS,CC048 and 060)

- PUMPDOWN PROCEDURE

- REFRIGERANT CHARGING

- Table 8 — Refrigerant Charging Methods (Carrier Approved Systems)

- CAIHIOI^; Do myi tmé