Pumpdown procedure, Refrigerant charging – Carrier 38GS User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

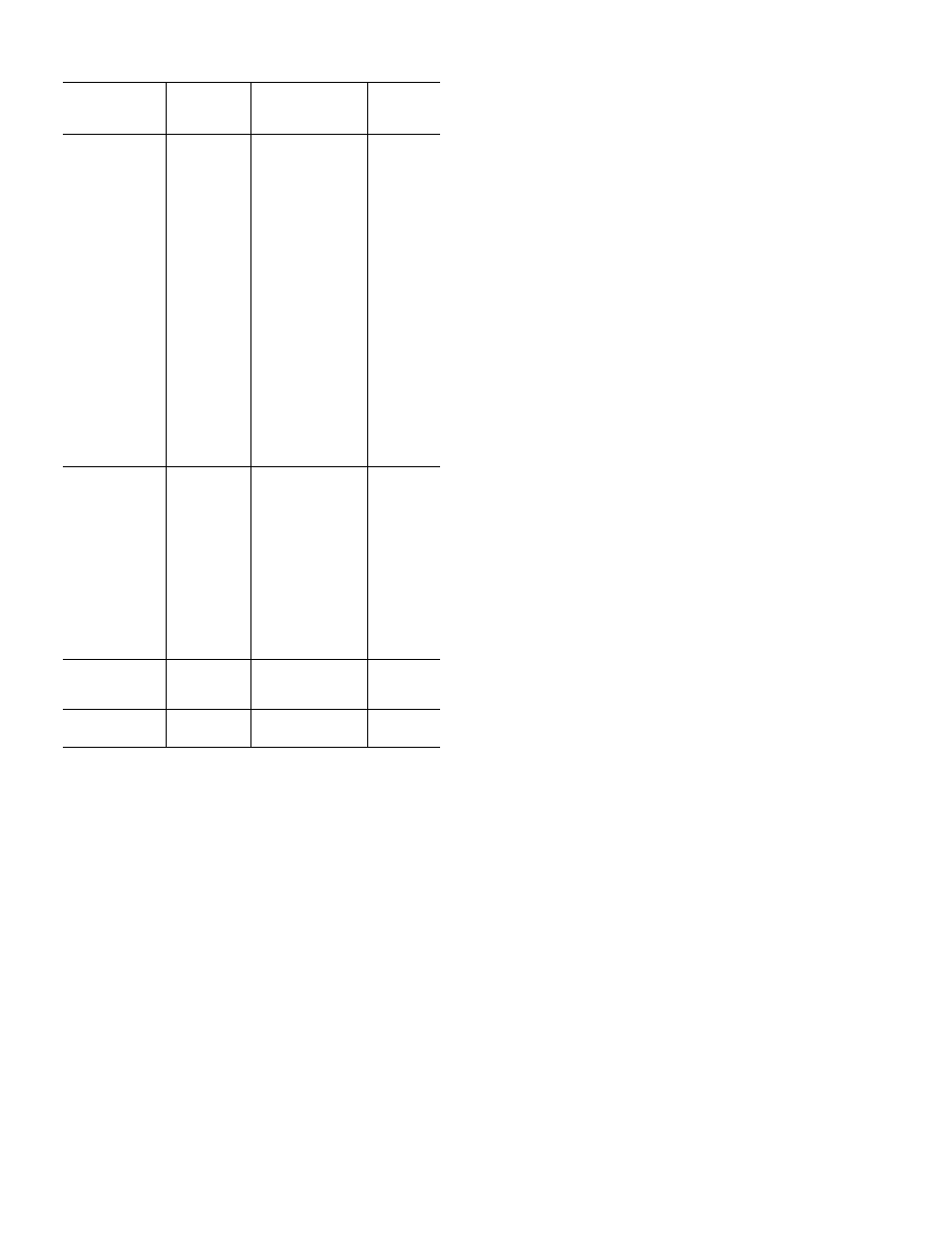

Table 7 — Compressor Data

COND

UNIT

V/PH

PRODUCTION

COMPR*

OIL

RECHG

(Oz)

38GS014__.

208/1

38GS400804

21

38GS014-..

230/1

38GS400804

21

38GS018200

208/1

38GC401994

21

38GS0182iO

208/1

MD2023CB

44

38GS018300

230/1

38GC400224

21

38GS0183IO

230/1

MD2023CB

44

38GS024200

208/1

38GL400314

42

38GS0242i0

208/1

MB2723CB

44

38GS024300

230/1

38GL400324

42

38GS024370

230/1

MD2723CB

44

38GS030200

208/1

38GC401984

42

38GS0302I0

208/1

MB3423CB

44

38GS030300

230/1

38GC401404

42

38GS0303i0

230/1

MC3423CB

44

38GS036200

208/1

38GC402004

46

38GS0362fO

208/1

MB4023CB

44

38GS036300

230/1

38GC401564

46

38GS0363i0

230/1

MC4023CB

44

38GS042___

230/1

38GS400424

46

38GS048___

230/1

PC5329AD

76

38GS060___

230/1

PC6728AB

76

38CC030.__

200/230/3

MF3423BC

44

38CC036___

200/230/3

MF4023CB

44

38CC036___

460/3

MH4023CB

44

38CC042___

200/3

38GR403364

46

38CC042___

230/3

38GR403364

46

38CC042__.

460/3

38GR403374

46

38CC048___

200/3

PF5326AD

76

38CC048___

230/3

PG5326AD

76

38CC048-__

460/3

PH5326AD

76

38CC060___

200/3

PF6725AA

• 76

38CC060___

230/3

PG6725AA

76

38CC060___

400/3

PH6725AA

76

38CE002___

230/1

MD2023CB

44

38CE003___

230/1

MD3023CB

44

38CE004___

230/1

MC3423CB

44

38CE045___

230/1

PC4629AD

76

38CE005___

230/1

PC5329AD

76

--------- Tabular data shown applicable to all models except

those shown italicized

000

* Refer to Service Parts Catalog for replacement

compressor

model

numbers

Single-phase

units

may

include

compressor

start assist device

PUMPDOWN PROCEDURE

The 38GS,CC,CE units may be pumped down in

order to make repairs on low side of system

without losing complete refrigerant charge.

1. Attach pressure gage to suction service valve

gage port.

2. Frontseat the liquid line valve.

3. Jumper low-pressure switch (if unit is so

equipped).

4. Start unit and run until suction pressure reaches

5 psig (see Caution).

5. Shut unit off and frontseat suction valve.

6. Vent remaining pressure to atmosphere.

REFRIGERANT CHARGING

The 38GS,CC,CE condensing units contain

correct operating charge for complete system when

connected to Carrier approved evaporators that are

the same size as condensing unit, with 25 ft or less

of tubing of recommended size. Charge adjustment

may be required on other systems.

Listed (Table 8) and described below are

recommended methods of checking, adjusting or

recharging Carrier approved systems. When recharg

ing these systems, evacuate system to 5000 mi

crons (29.7-in. vacuum), and weigh in charge

shown in Table 5. When system is not evacuated,

subtract the following amount from total charge.

38GS014,018,024; 38CE002 - .11 lb (1.6 oz)

38GS030,036; 38CE003,004; 38CC030,036 - .21

lb (3.2 oz)

3 8 G S 0 4 2 , 0 4 8 , 0 6 0 ;

3 8 C C 0 4 2 , 0 4 8 , 0 6 0 ;

38CE045,005 - .31 lb (4.8 oz)

(Dial-a-charge charging cylinder is an accurate

device used to recharge systems by weight. These

cylinders are available at refrigeration supply

firms.) After weighing in charge, check or adjust

charge using the Chargemaster® charging device,

charging chart or sight glass method as recom

mended in Table 8. Refer to Carrier Standard

Service Techniques Manual, Chapter 1, for system

evacuation — dehydration instructions.

When 38GS,CC,CE condensing units are con

nected to other than a Carrier evaporator, evacuate

system and weigh in charge shown in Table 5 or

use sight glass method of recharging (38CC thermal

expansion valve systems only).

I

10