Compressor service, Unit protection – Carrier 38GS User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Do not connect charging hoses to capillary-

controlled system during initial start procedure.

(Loss of charge from this procedure may result in

capacity reduction.) If necessary to add manifold

f • gages for servicing, refer to Carrier Standard

Service Techniques Manual, Chapter 1, pages 1—5,

Fig. 8, for bypass method of returning charge to

system. (A charging hose valve must be used to

accomplish bypass of refrigerant on all units.)

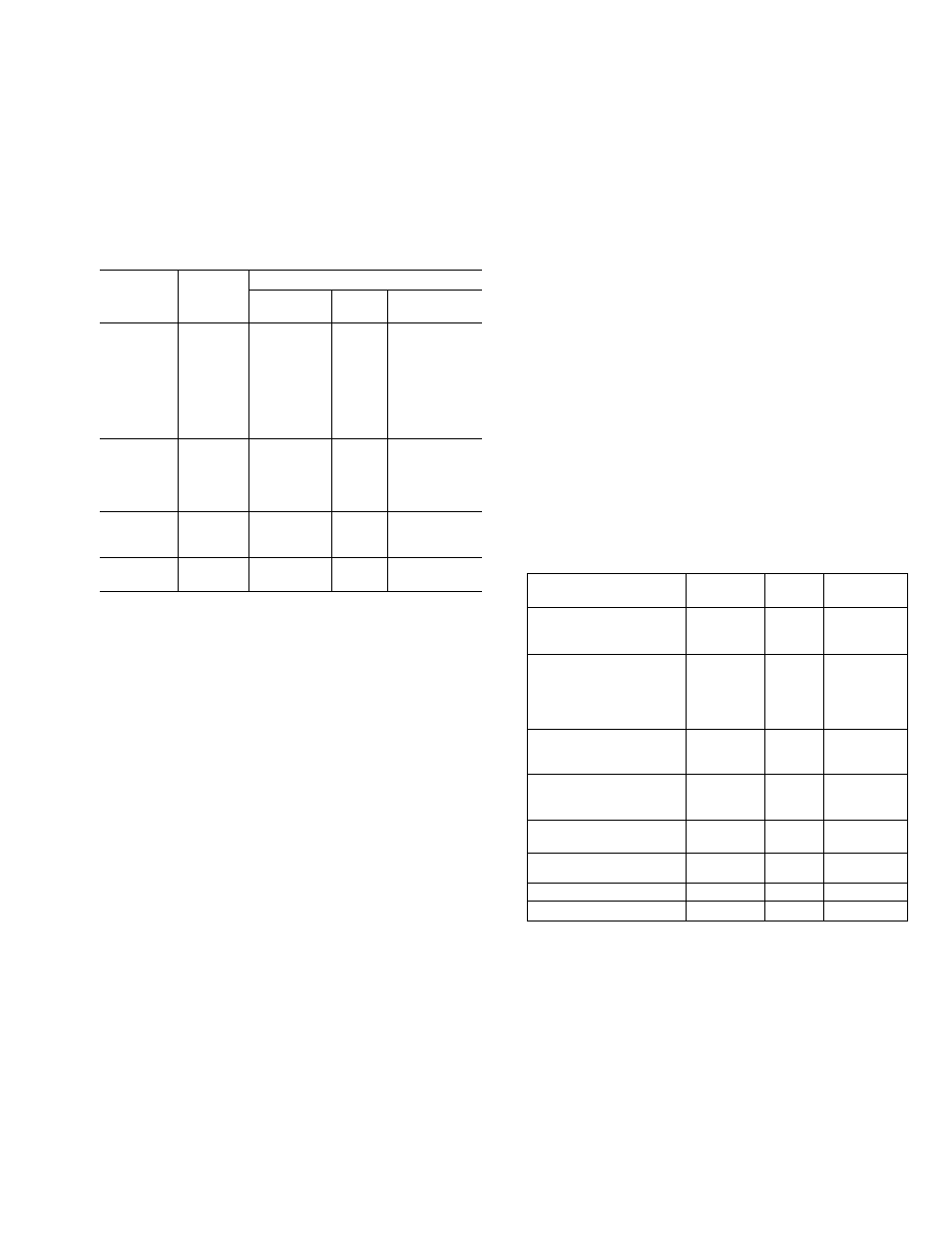

Table 5 — Service Data

CONO

UNIT

R-22

CHG*

(lb—oz)

CONDENSER FAN

Rpm

Diam

(in.)

Cfm

38GS014

3- 0

2600

38GS018

3- 0

2600

38GS024

3- 0

2600

38GS030

3- 2

2600

38GS036

3-M

2600

38GS042

4-12

2800

38GS048

5- 3

2800

38GS060

5- 3

2800

38CC030

3- 2

2600

38CC036

3-14

2600

38CC042

3-12

1060

17/2

2800

38CC048

5- 3

2800

38CC060

5- 3

2800

38CE002

4- 7

2600/2100

38CE003

4-11

1070/870

17/2

2600/2100

38CE004

5- 2

2800/2300

38CE045

38CE005

5- 6

5-11

975/800

17/2

2700/2200

2700/2200

"■Factory refrigerant charge adequate for complete system when

connected to Carrier approved evaporators mat are the same

size as condensing unit, with 25 ft of tubing

COMPRESSOR SERVICE

Unit Single-Phase Compressors of the Split Capaci

tor (PSC) Type

require an equalized system pres

sure to start. When supply voltage is within 10%

limit and compressor does not start, give com

pressor a temporary capacitance boost. See Carrier

Standard Service Techniques Manual, Chapter 2,

for details. Use a 130-mfd start capacitor. Connect

wires with insulated probes to each capacitor

terminal. Touch probes to each side of run

capacitor or to compressor motor terminals R and

S. Start compressor; pull probes away after 3

seconds. Discharge start capacitor. Run compressor

for 10 minutes, then shut off and allow system

pressure to equalize. Try restarting without boost

capacitor. If after 2 attempts (without boost

capacitor) the compressor does not start, add an

accessory start capacitor relay package.

Unit Single-Phase Compressors That are Equipped

With a Compressor Start Thermistor

(PTC device);

if compressor will not start, check the thermistor

with an ohmmeter as described below. (If evap

orator coil does not have a bleed-type expansion

device, it may be necessary to remove PTC device

and replace with accessory start capacitor and

relay.)

CHECKING START THERMISTOR

1. Shut off all power to unit and wait 5 minutes

for thermistor to cool to outdoor temperature.

2. Measure resistance of thermistor with ohmmeter.

Normal resistance readings are 50 to 90 ohms at

75 F outdoor temperature.

3. If ohmmeter resistance reading is 0 or much

higher than 90 ohms the thermistor is defective

and must be replaced.

If start thermistor is good and compressor will

not start, disconnect the thermistor from starting

circuit and give compressor a temporary capaci

tance boost as described above. Run compressor

for 10 minutes, then shut off and allow system

pressure to equalize. Reconnect start thermistor

and try restarting compressor without boost capac

itor. If after 2 attempts the compressor does not

start, remove thermistor and add an accessory start

capacitor relay package.

38CC Units

— Compressor start capacitor and relay

or thermistor (PTC) are not required on 3-phase

38CC units.

Safety Devices

— Refer to Table 6 for particular

safety controls that each unit is equipped with.

Table 6 — Compressor Safety Controls

SAFETY CONTROLS

COND

38GS

ENSING 1

38CC ^

NITS

38CE

INTERNAL CURRENT-

TEMP SENSITIVE

OVERLOAD

014,018

024,030

036,042,048

030,036,

042,048

002,003,

004,045,

005

INTERNAL THERMO

(Pilot Duty)

LOW-PRESS. SWITCH

060

060

030, Ò3C

042,048,

060

Accessory

HIGH-PRESS. SWITCH

-

030,036,

042,048.

060

-

CRANKCASE HEATER

Accessory

030,036,

042,048.

060

Accessory

OUTDOOR FAN

THERMOSTAT

-

-

002,003,

004,045,005

TIME G U A R D ®

-

030,036,

042

-

CPCS

060

048,060

-

SOLID STATE TIMER

-

-

045,005

CPCS

Compressor Protection Control System

UNIT PROTECTION

Internal Current And Temperature Sensitive Over

loads

reset automatically when internal motor

temperature drops to a safe level (overloads may

require up to 30 minutes to reset). When an

internal overload is suspected of being open, check

by using an ohmmeter or continuity tester. If

necessary, refer to Carrier Standard Service

Techniques Manual, Chapter 2, for complete

instructions.