Start-up instructions, Start procedure, Fi-lb lorquc »hen – Carrier 38GS User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

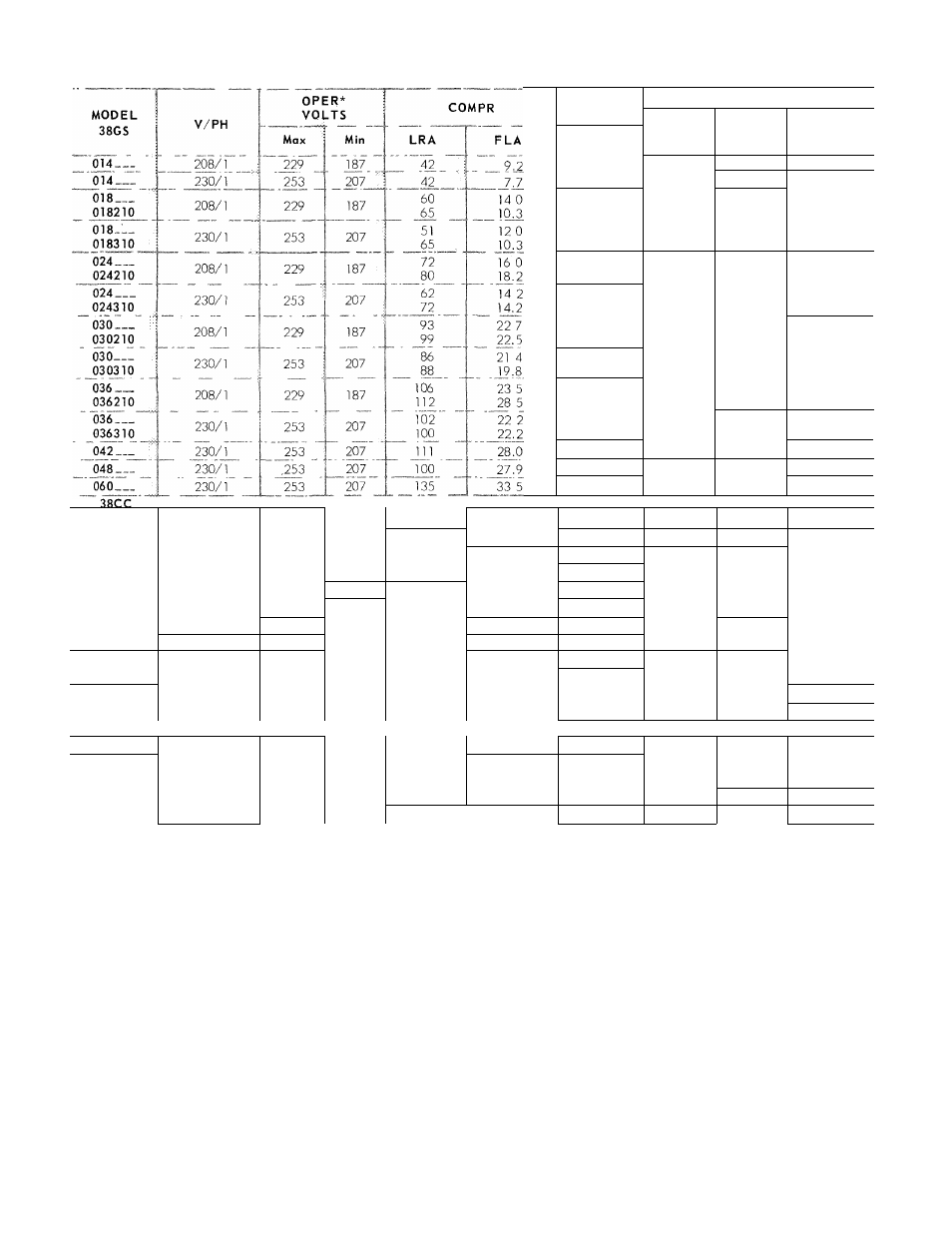

Table 4 — Electrical Data

FAN

BRANCH CIRCUIT

Wire

Sizef

(AWG)

Max

Ft

Wiref

Fusei

Amps

FLA

2.4

14

40

20

2.1

14

33

20

2 4

12

28

30

2,4.........

___12______

..37..........

20

2 1

12

36

25

2.1

14

19

25

2 4

10

40

35

2.4

10

35

40

2 1

12

31

30

2.1

12

31

30

2 4

8

45

50

2.4

8

45

50

2 1

10

34

30

2.1

10

36

45

2 4

8

44

55

2.4

8

36

65

2 1

10

33

50

2.1

10

33

50

2.1

8

41

65

2.1

8

42

55

2 1

6

54

75

030___

200/230/3

253

180

70/60

13 0/11 5

2 0/2 .0

12

49

30/25

036___

200/230/3

253

180

80/70

14 0/12 6

2 0/2 0

12

45

30/30

036___

460/3

506

414

35

6 5

1.0

14

91

15

042___

200/3

220

180

92

17 0

2 0

10

49

35

042___

230/3

253

207

92

15 8

2 0

10

58

35

042___

460/3

506

414

46

7 8

1 0

14

100

15

048___

200/3

220

180

90

18 6

2 0

10

46

40

048___

230/3

253

207

78.5

16.1

2.0

10

60

35

048___

460/3

506

414

39 3

8 3

1 0

14

100

20

060___

200/3

220

180

n o

23 0

2.0

8

'■ 67

50

060___

230/3

253

207

100

20 5

2 0

10

47

45

060___

460/3

506

414

50

10 3

1 0

1 4

1 74

20

38CE

002___

230/1

253

207

65

10.3

2-.1

12

42

25

003___

230/1

253

207

82

16 8

2 1

10

42

35

004___

230/1

253

207

~88

19.8

2.1

10

36

45

045___

230/1

253

207

88

23.9

2.1

10

31

55

005___

230/1

253

207

100

27.9

2 1

8

42

60

FLA

— Full Load Amps

LRA

— Locked Rotor Amps

______Electrical data shown applicable to all units for

which complete model number is not shown

•Permissible limits of the voltage range at which the units

will operate satisfactorily

(■Copper wire sizes Aluminum field wiring may be used when splice-

connected to copper pigtails from unit with factory-supplied wire nuts

Use latest National Electrical Code for aluminum wire sizing

^Maximum dual element fuse size

NOTE Control circuit voltage is 24 volts on all units

START-UP INSTRUCTIONS

If unit is equipped with crankcase heater,

energize heater a minimum of 24 hours before

starting unit To energize heater only, set thermo

stat at “Off” position and close electrical dis

connect to condensing unit.

Units with Time Guard® circuit or solid state

time-delay may not start for approximately 4 to 5

minutes after thermostat closes. See compressor

controls, pages 7 and 8.

Start Procedure

1. Backseat (open) liquid and suction line service

valves.

4 Do exscod

iighiiiiing.

ov«rtii^i

6

fi-lb lorquc »hen

2. Set thermostat selector switch at "Off.”

3. Set room thermostat at desired temperature.

4. Close electrical disconnects energizing entire

system.

5. Set room thermostat at “Cool” and fan switch

as desired (“Fan”) (“Auto.”).

Check system refrigerant charge. See Refrig

erant Charging.

Motors and controls will operate satisfactorily

in a range from 10% above to 10% below nominal

unit voltage (Table 4).