Fan motor removal, Condenser, Lubrication – Carrier 38GS User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Leaking Mechanical Connection

— Frontseat con

densing unit service valves and relieve refrigerant

pressure in tubing. Back locknut off Compatible

Fitting onto tube. Cut fitting between threads and

seal ring head as shown in Fig. 10. Remove tubing

section remaining in threaded portion of fitting.

Discard locknut.

Clean, flux, and insert new tube end into

remaining portion of Compatible Fitting. Wrap

valve base in wet rag. Heat and apply low tempera

ture (450 F) solder.

Leaking Sweat Connection

— Frontseat service

valves and relieve refrigerant pressure in tubing.

Clean and flux area around leak and apply low

temperature (450 F) solder.

Evacuate or purge evaporator coil and tubing

system. Add refrigerant charge (see charging

instructions).

COMPATIBLE FITTING REPAIR

Off íA&m

Fan Motor Removal

1. Shut off power to unit.

2. Remove unit top access cover and fan grille.

3. Disconnect fan motor wires from fan capacitor

and control relay or contactor. Pull wires out of

control box.

4.

Remove fan from motor shaft by pulling

upward on fan hub.

5.

Loosen bolt holding fan motor to motor

mounting bracket. Remove motor thru top of

unit. To replace motor, place motor on self

positioning motor mounting flanges and re

tighten bolt.

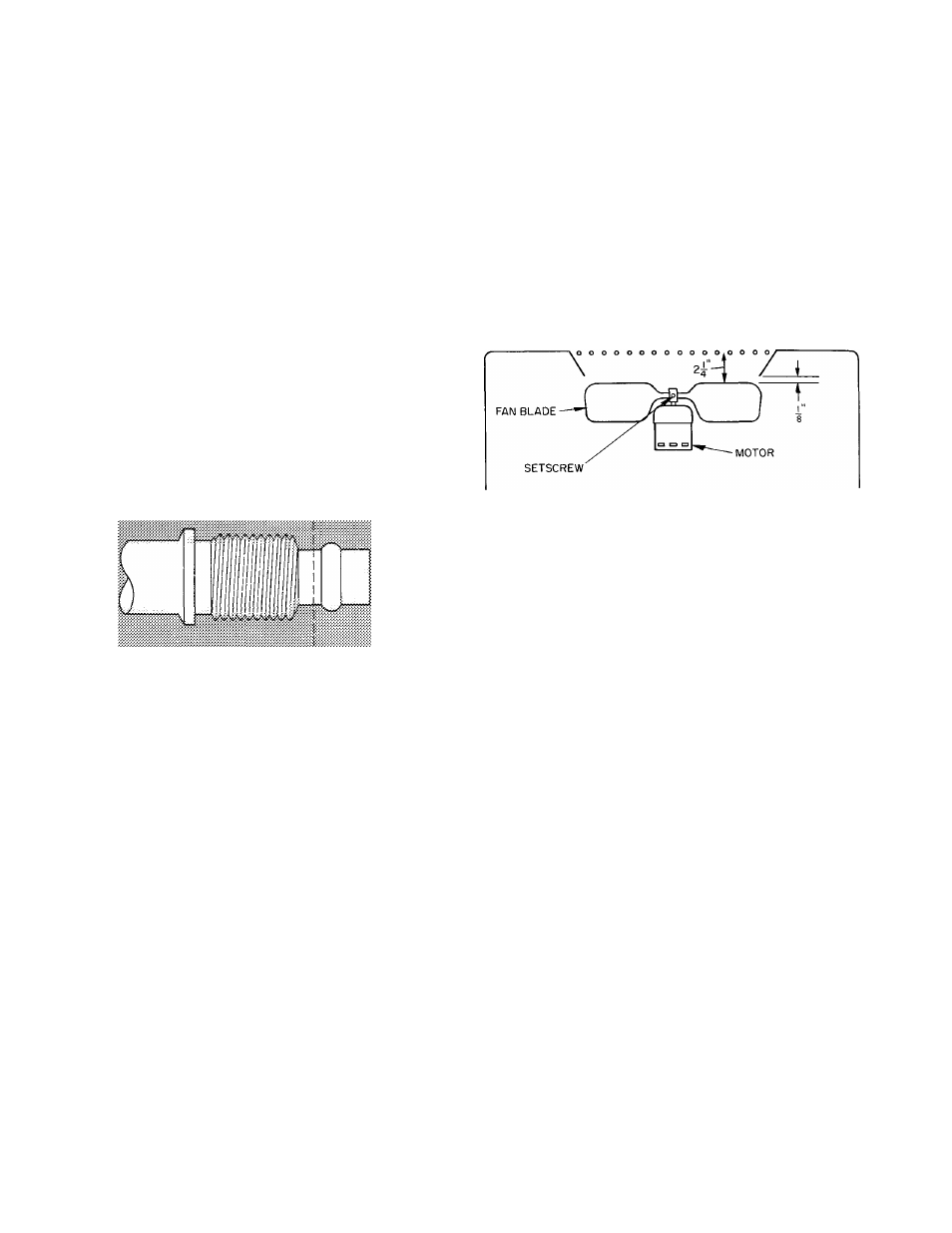

Fig. 11 — Condenser Fan Position

Fig. 10 — Repair of Mechanical Connection

CONDENSER

Coil Cleaning

— Ensure power to unit is shut off

Clean the condensing unit coil at the beginning of

every cooling season or more often if required. Use

ordinary garden hose at a pressure high enough to

clean efficiently. For best results, unscrew and

remove unit top cover (grille). Insert hose nozzle

between fan blades and spray coil fins from

inside-to-outside the unit. If unit has a double-row

coil, loosen screws to separate coils, and flush dirt

toward outside of both coils. Flush dirt from base

pan by spraying water thru top of unit. Avoid

splashing mud on coil or water on the fan motor.

Metal Fan

— Required fan position is shown in Fig.

11. Adjust fan by loosening setscrew and moving

fan blades up or down.

Plastic Fan

is correctly positioned in unit by

placing fan on motor shaft — align flat mark on top

of fan hub with flat on shaft. Press down evenly on

top of fan hub until shaft bottoms in fan hub.

LUBRICATION

Fan Motor Bearings

— Oiling holes are provided at

each end of current condenser fan motor. Remove

fan motor and lubricate motor with 32 drops (16

drops per hole) of SAE-10 nondetergent oil at

intervals described below:

a.

Annually, when environment is very dirty,

ambient temperature is higher than 105 F and

average unit operating time exceeds 15 hours a

day.

b. Every 3 years when environment is reasonably

clean, ambient temperature is less than 105 F

and unit operating time averages 8 to 15 hours

a day.

c.

Every 5 years when environment is clean,

ambient temperature is less than 105 F and unit

operating time averages less than 8 hours a day.

Compressor

contains factory oil charge. When oil is

lost, see Table 7 for oil charge and Carrier Standard

Service Techniques Manual, Chapter 1, page 1—21,

for instructions. Use Carrier PP33-1, Texaco

Capella B or Suniso 3G oil.

1 4