Carrier 38GS User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

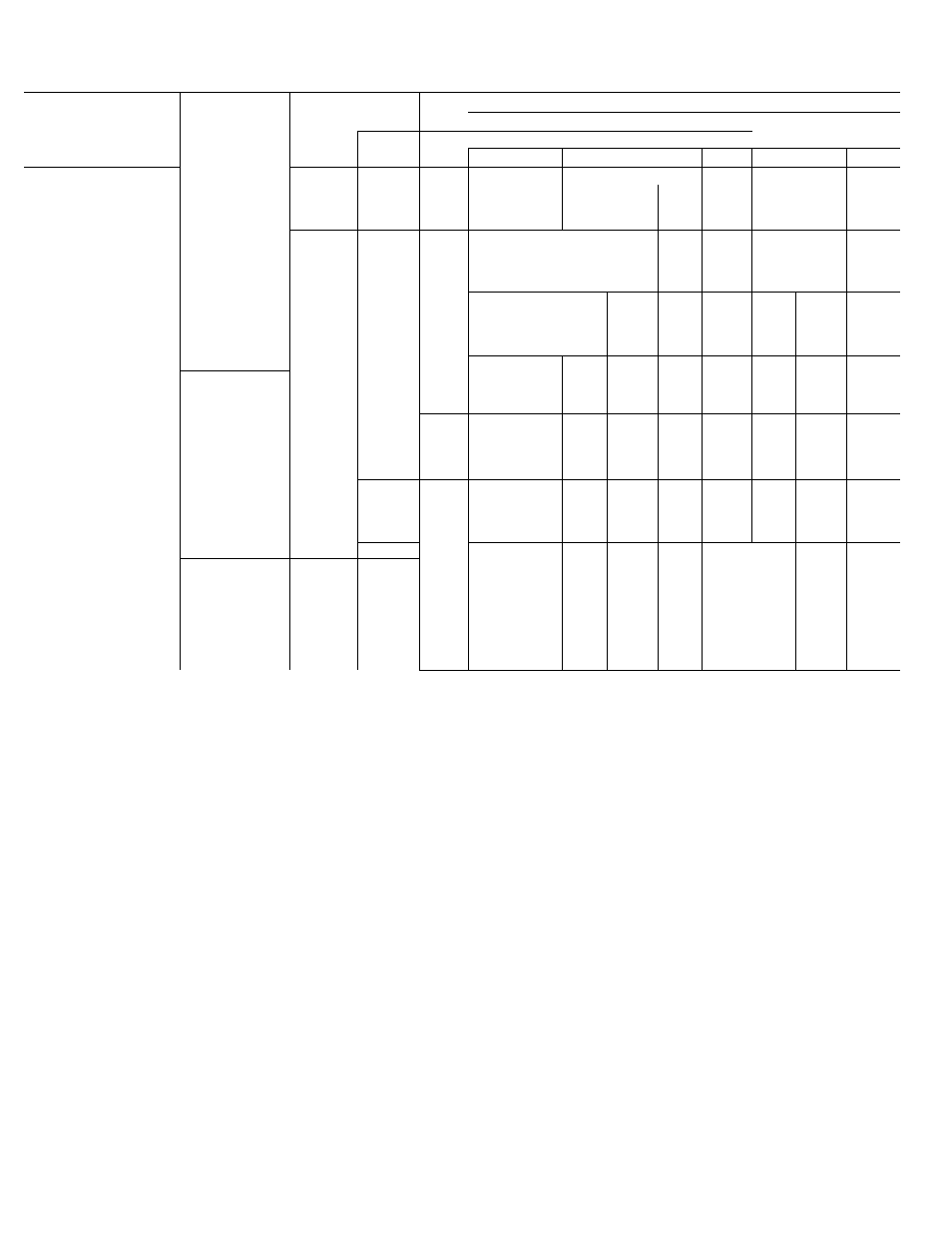

Table 3 — Field-Supplied Piping Data

MAX COND

REFRIGERANT LINE LENGTH (ft)

COND

REFRIG

UNIT HT (ft)

25- 50 51»

7S

7&~

1

m

f 3 UNIT

CONTROL

Above

Be low

Line Diameter (in* OD)

X-

Evap

Evap

Suet

Liq

iÄiii

Litj 1

LE

íj

TXV

90

90

'

38GS014,

38GS018

Cap. Tube

or

AccuRater'*'^

150

50

V

'8

V»

'x

iiiiii

lili

IH

iiiiii

¡Mil

38GS024

TXV

Cap. Tube

yo

150

90

50

%

%

IIBI

■

AccuRater

38GS030,

38CC030,

38CE002

Cap. Tube

or

AccuRater

150

__

50

%

Vs

iiiiiiiiiii

wmmmmmmm

ilM

MB

ilBi

%

38GS036,

38CC036,

38CE003

TXV

90

90

Cap. Tube

or

AccuRater

150

50

%

V» T

ISl

38GS042,

38CC042,

38CE004

TXV

90

90

Cap Tube

or

AccuRater

150

50

/4

V»

N

s

TXV

90 ■

90

38GS048,

38CC048

Cap Tube

or

AccuRater

150

50

%

% liM

T

%

■

TXV

90

90

38CE045

Cap. Tube

or

150

50

1%

% Iliiii

k

V

11

»

AccuRater

Äiii

38GS06 0,

38CC060,

38CE005

L^y

Cap. Tube

or

AccuRater

90

150

90

50

IV»

V»

*

Í...............

Cap. Tube

TXV

Crankcase heater and liquid line filter-drier required

on 38GS and 38CE units Accessory start capacitor

with

relay

also

required

on

38GS

unit,

but

not

normally

required

on

38CE

units

See

Compressor

Service Reduce liquid line diameter by 1/8-in OD

(min 1/4-in OD) when evaporator is 20 ft or more

below condensing unit

■ Capillary Tube

- Thermal Expansion Valve

NOTES

1 The following system modifications are required adjust

refrigerant charge on systems with over 25 ft separation

between

condensing

unit

and

evaporator

(See

Refrigerant

Charging ) Adjust system oil charge as described in Note 2

Oil

charge

adjustment

add

1%

of

nominal

oil

charge

in

system (Table 7) for each 10 ft of refrigerant line length

above 50 feet Eor example, a system that has a 50-oz oil

charge with 1 50 ft of interconnecting piping requires 5 oz of

additional oil as shown below:

150 ft - 50 ft = 100 ft

100 ft -E 10 ft = 10 ft

1 0 x 1 % = 1 0 % ( 1 0 )

10

X

50 oz = 5 oz

Do not permit condensing unit to short cycle, particularly on

applications

with

long

vertical

line

lengths

Correct

short

cycling condition immediately

Connection Procedure

— When making tubing

connections, be sure to provide clearance at unit

for electrical connections.

Connect refrigerant liquid and suction lines to

condensing unit, Fig. 1. Unit Compatible Fittings

permit 2 methods of refrigerant line connection;

mechanical (quick connect) or sweat connection.

Make suction line connection first.

38CE045,005, 38GS060 AND 38CC060 UNITS -

Remove suction line adapter taped to compressor

suction line. Connect 3/4-in. end of adapter to unit

suction line Compatible Fitting. Sweat connect

refrigerant suction line to 1 1/8-in. end of adapter.

Connect liquid refrigerant line to unit.

MECHANICAL CONNECTION (Mate one set of

connections at a time.)

1. Loosen nut on Compatible Fitting one turn. Do

not remove.

Remove plug and be sure 0-ring is in the groove

inside the Compatible Fitting.

Cut tubing to correct length.

Use gage on tag attached to service valve to

mark tube end for correct insertion depth.

Insert tube into Compatible Fitting until it

bottoms. (Tube should be inserted at least as

far as mark on tubing.)

Tighten nut until it bottoms on back coupling

flange.

2

.

3.

4.

5.