Warning, Power supply, Power wiring – Carrier 38AH024-034 User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

3. Size the suction line from the evaporator through the

riser for high velocity. Suction piping for the high

velocity section should be selected for about 0.5° F

(0.3° C) frietion loss. If a 2° F (1.1° C) loss is allowed

for the entire suction line, 1.5° F (0.8° C) is left for the

balance of the suction line and it should be sized on that

basis.

Check that the high-velocity sizing is ade

quate for oil return up the riser.

If an oil return connection at the bottom of this suction

header is supplied with an evaporator, this connection must

be teed-in ahead of first mixing elbow. When the condens

ing unit is below the evaporator, the riser at the evaporator

does not have to extend as high as the top level of a given

evaporator circuit. After a 15-diameter riser has been pro

vided, the suction line may elbow down immediately.

SAFETY RELIEF — A fusible plug is located on unit liq

uid line before the liquid valve. Other fusible plugs are

located on the compressor(s) and on the suction line(s).

VAV (Variable Air Volume) APPLICATIONS — Field-

supplied suction line accumulators (one per circuit)

(Replacement

Components

Division,

Carrier

Part

No. KH73LZ001) are required for VAV applications in

outdoor units.

A

WARNING

Failure to install accumulator in outdoor unit VAV ap

plications may VOID warranty.

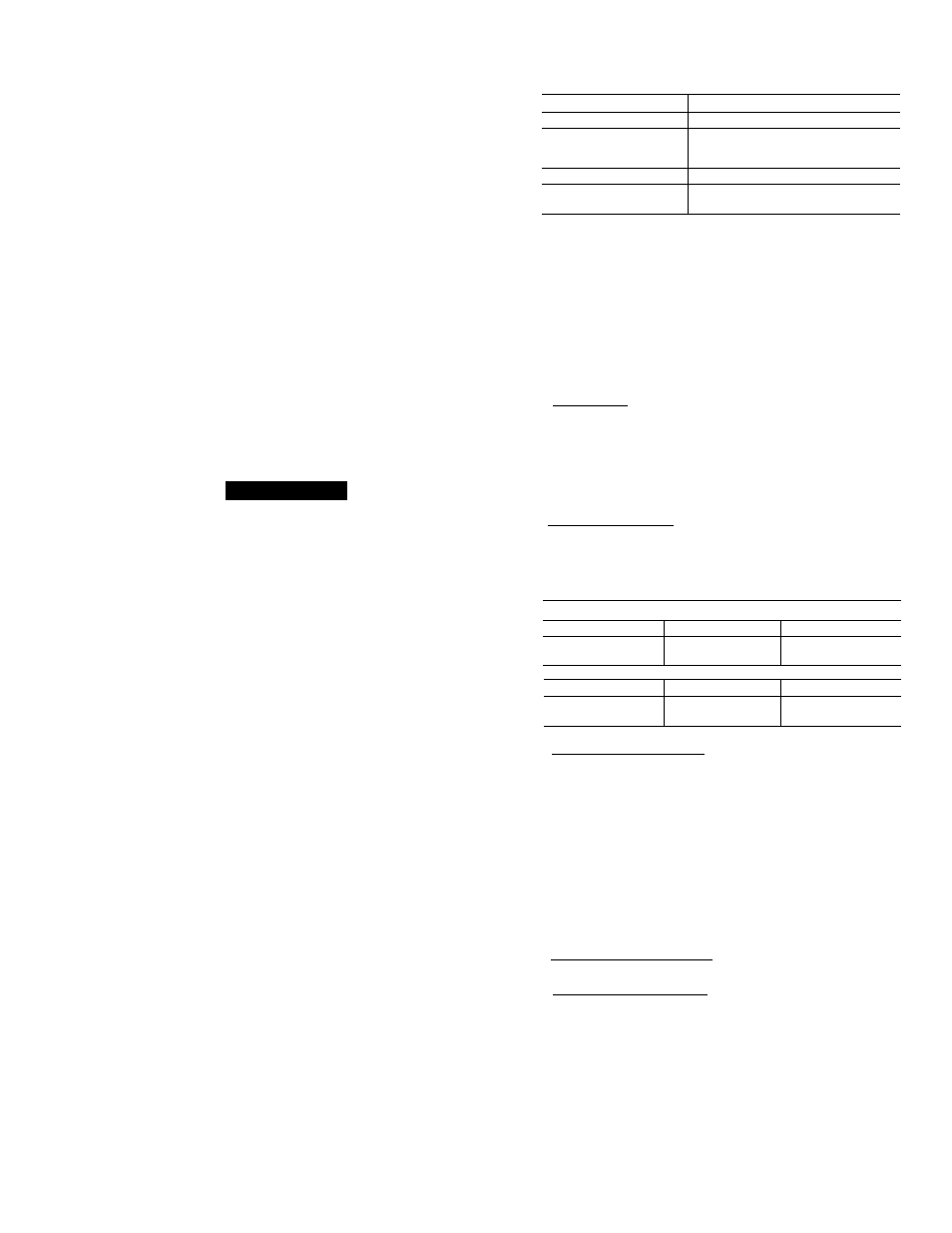

4. Maximum field wire sizes allowed by lugs on terminal

Power Supply

— Electrical characteristics of available

power supply must agree with unit nameplate rating. Sup

ply voltage must be within limits shown in Table 3.

IMPORTANT: Operating unit on improper supply volt

age, or with excessive phase imbalance, constitutes

abuse and may affect Carrier warranty. See Unbal

anced 3-Phase Supply Voltage, page 8.

Power Wiring

— All power wiring must comply with

applicable local and national codes. Install field-supplied

branch circuit fused disconnect(s) per NEC (National Elee-

trical Code [U.S.A. Standard]) of a type that can be locked

OFF or OPEN. Disconnect(s) must be within sight from

and readily accessible from unit in compliance with NEC

Article 440-14.

GENERAL WIRING NOTES

1. A crankcase heater is wired in the eontrol cireuit so it is

always operable as long as power supply disconnect is

on, even if any safety device is open or unit stop-start

switch is off. It is protected by a 5-amp circuit breaker

in control power.

2. The power circuit field supply disconnect should never

be open except when unit is being serviced or is to be

down for a prolonged period. When operation is re

sumed, crankcase heater should be energized for 24 hours

before start-up. If unit is to be shut down for a pro

longed period, it is recommended that the suction and

discharge valves be closed to prevent an excessive ac

cumulation of refrigerant in the compressor oil.

3. Power entry is at compressor end only.

block are as follows:

V-PH-HZ

WIRE SIZE

208/230-3-60

350 kcmil (177.90 sq mm)

380-3-60

460-3-60

575-3-60

2/0 AWG (67 42 sq mm)

230-3-50

350 kcmil (177.90 sq mm)

346-3-50

400-3-50

2/0 AWG (67.42 sq mm)

5. Terminals for field power supply are suitable for cop

per, copper-clad aluminum, or aluminum conductors.

Insulation must be rated 167 F (75 C) minimum.

CONDENSER FANS — The fans must rotate counter

clockwise when viewed from above. If necessary, correct

direction of fan rotation by interchanging any 2 power

input wires at disconneet switch. Affix crankcase heater

decal (located in installer’s packet) to unit disconnect

switch.

FIELD CONNECTIONS

1. Main Power — Bring wires from the fused disconnect

switch through hole in bottom rail of unit to control box

11

12

13

2

.

(Fig. 6) and connect to terminals

on line side of terminal block TBl (see Fig. 7 or 8). To

comply with NEC Article 440-14, the disconnect must

be located within sight from and readily accessible from

the unit.

24-v Control Power — Units have single point power

connections. Control circuit is directly connected inter

nally to unit. Maximum 24-v control circuit is 3.2 amps.

NOTE; For wire runs, use the following sizes of insu

lated wire;

Ft

0-50

50-75

Over 75

No 18 AWG

No 16 AWG

No 14 AWG

35 C Min

35 C Min

35 C Min

0-15.2

15.2-22.9

Over 22.9

0 82 sq mm

1.30 sq mm

2 08 sq mm

35 C Min

35 C Min

35 C Min

3. Control Circuit Interlock — An airflow switch may be

installed in the indoor air handler to prevent unit from

running when indoor air is not flowing. This switch

(Carrier part no. HR81JE001) is available from Service

Parts Center, or equivalent can be field supplied. This

should be electrically interlocked in the control circuit

as shown on the label diagram affixed to the access panel

on end of unit. Note that for a single air handler with

constant volume controls (those shown in Fig. 7 and 8),

the airflow switch must be used in combination with a

relay having 2 sets of normally open contacts (Carrier

part no. HN61KK040 or equivalent). For wiring, see

unit label diagram on inside of unit access door.

4. ModuPanel™ Connections — Refer to Fig. 9 and 10 for

field connections.

5. Transformer Connections — See unit wiring label dia-

gram, notes 1 and 2, located behind compressor com

partment end access door.

IMPORTANT: Ensure power to the crankcase

heater is always on (except when servicing the

unit). If circuit breakers inside unit shut down

the compressor and condenser fans, crankcase heater

remains on.