A warning – Carrier 38AH024-034 User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Mounting Unit

— When unit is in proper location, use

of mounting holes in base rails is recommended for secur

ing unit to supporting structure, or for mounting unit on

vibration isolators if required. Fasteners for mounting unit

are field supplied. Be sure to mount unit level to ensure

proper oil return to compressors.

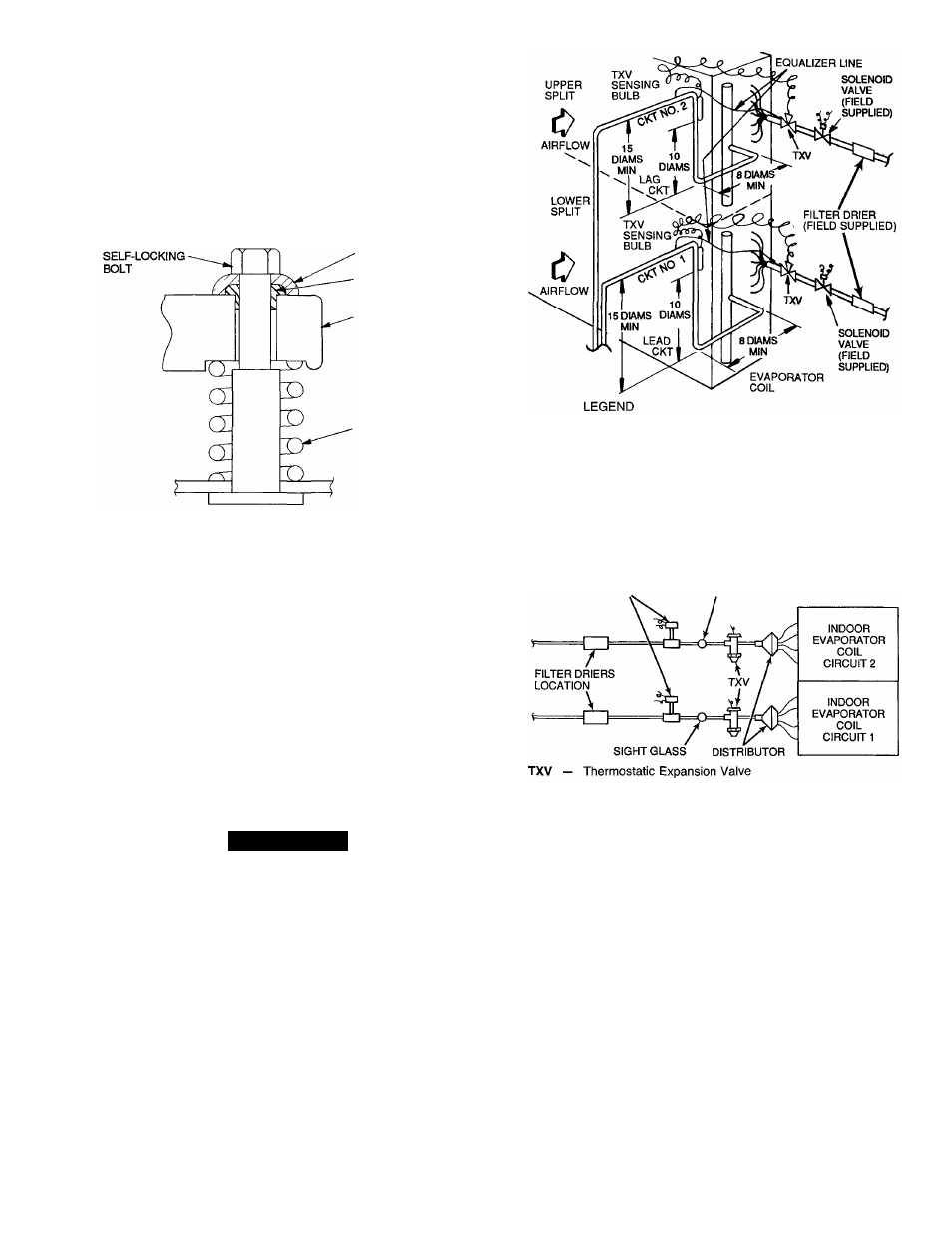

Compressor Mounting

— As shipped, compressor

is held down by 4 bolts. After unit is installed, loosen each

bolt until the snubber washer can be moved with finger pres

sure. See Fig. 3.

SNUBBER FLANGED

WASHER

NEOPRENE

SNUBBER

COMPRESSOR FOOT

ISOLATION SPRING

Fig. 3 — Compressor Mounting

TXV — Thermostatic Expansion Vaive

NOTES:

1. Lower section is first on and last off.

2. For more complete piping information, refer to Carrier System

Design Manual, Part 3, or E20-II refrigerant piping computer

program

Fig. 4 — Suction Line Piping to Unit with

2-Section Coil Split

INSTALLATION

Refrigerant Piping Connections

— Line sizes de

pend on length of piping required between condensing unit

and evaporator. See Table 2A or 2B. It is important to con

sider liquid lift and compressor oil return. Refer to Part 3 of

Carrier System Design Manual for line sizing information,

and Fig. 4 for recommended piping details.

Solenoid Drop Refrigerant Control

— All units

are factory wired to operate on solenoid drop refrigerant

control. A field-supplied liquid line solenoid valve must be

installed in the liquid line ahead of the indoor coil. See

Fig. 5. Wires from solenoid valve do not need to be in con

duit as coil voltage is 24 v (class 2 circuit).

A WARNING

Failure to properly install liquid line solenoid at the in

door unit as described, without Carrier authorization,

may VOID warranty.

fie

L

d

-

supplied

SOLENOID VALVE

SIGHT GLASS

Filter Drier and Moisture Indicator

— Every unit

should have a filter drier and a sight glass (moisture indi

cator) field installed. Select the filter drier for maximum

unit capacity and minimum pressure drop. Figure 5 shows

recommended locations of filter drier(s) and sight glass(es).

Complete the refrigerant piping from the evaporator to the

condenser before opening the liquid and suction lines at the

condensing unit.

Receiver

— No receiver is provided with the unit; it is

recommended that one not be used.

Piping Procedure

— Do not remove run-around pipe

from suction and liquid line stubs until piping connections

Fig. 5 — Liquid Line Solenoid Valve,

Filter Drier(s), and Sight Glass Locations

are ready to be made. Pass nitrogen or other inert gas through

piping while brazing, to prevent formation of copper oxide.

Install field-supplied thermostatic expansion valve (TXV)

in liquid line ahead of each evaporator section.

SUCTION PIPING AT EVAPORATOR AND TXV BULB

LOCATION (See Fig. 5) — The purpose of these recom

mendations is to achieve good mixing of the refrigerant leav

ing the evaporator suction header for proper sensing by the

TXV bulb.

1. A minimum of two 90 degree elbows must be installed

upstream of the expansion valve bulb location.

2. The TXV sensing bulb should be located on a vertical

riser where possible. If a horizontal location is neces

sary, secure the bulb at approximately the 4 o’clock

position.

Copy continued on page 7.