Winter start control, Head pressure control, Fig. 15 — capacity control valve – Carrier 38AH024-034 User Manual

Page 20: Table 5 — fan cycling controls

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

TOP OF FAN ORIFICE

FILL HOLE IN FAN HUB

PROP LOCATION

“A” in. (mm)

60 Hz

38AH024-034

3.5 (89)

50 Hz

38AH024-034

4.3 (109)

Fig. 14 — Location of Prop on Motor Shaft

from Outside of Orifice Ring

Table 4 — Pressure Switch Settings, psig (kPa)

HIGH PRESSURE

LOW PRESSURE

Cutout

Cut-in

Cutout

Cut-in

426 ± 7

320 ± 20

27 ± 3

44 ± 5

(2937 ± 48)

(2206 ± 138)

186 ± 21)

(303 ± 34)

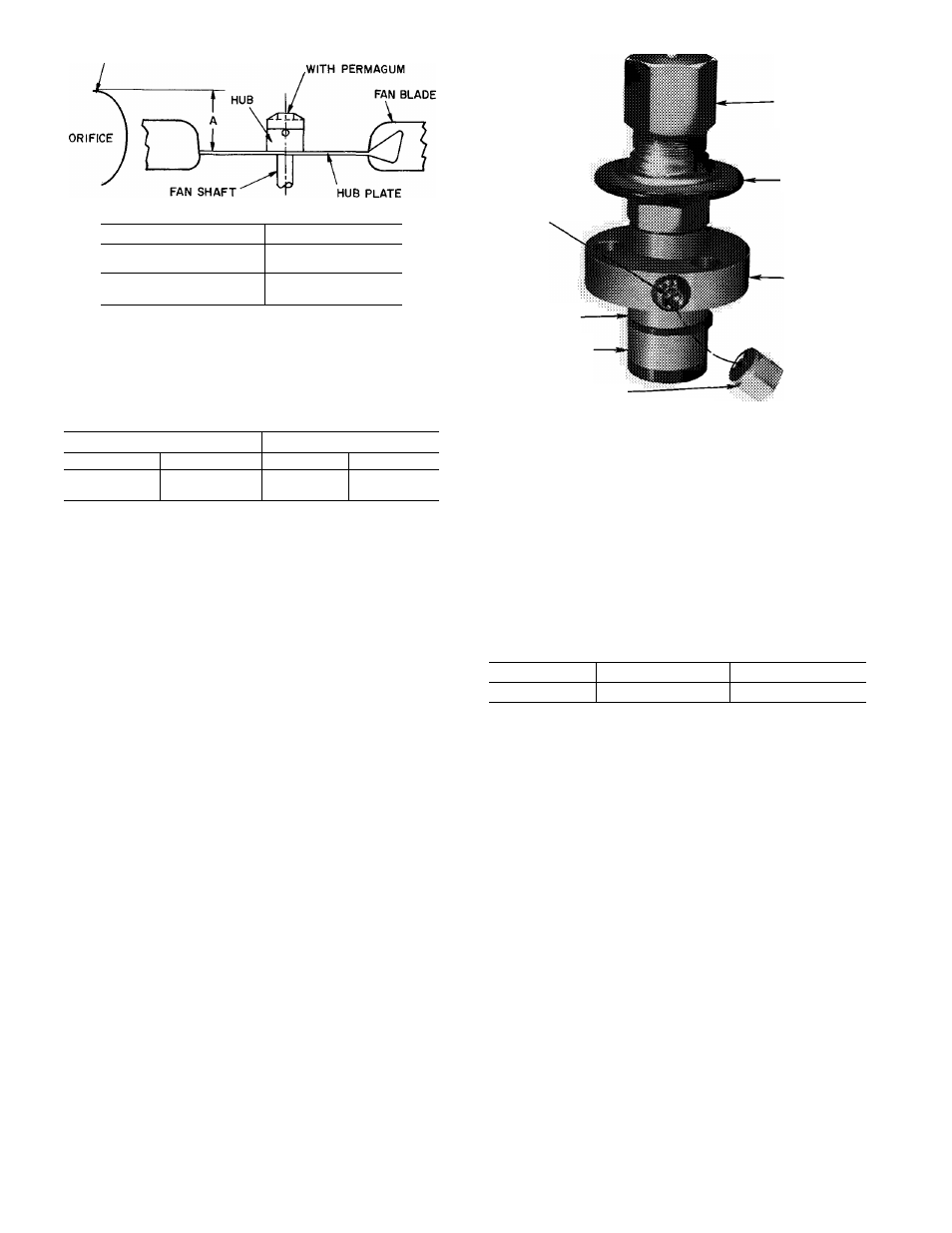

PRESSURE

DIFFERENTIAL

ADJUSTMENT

SCREW

CONTROL

SET POINT

ADJUSTMENT

-NUT

POWER HEAD

VALVE BODY

BYPASS

PISTON RING

BYPASS PISTON

DIFFERENTIAL SCREW

SEALING CAP

(CAP MUST BE REPLACED

TO PREVENT REFRIGERANT LEAKAGE)

Fig. 15 — Capacity Control Valve

Winter Start Control

— Purchase accessory Carrier

part no. 38AE900021 for winter start control.

Head Pressure Control

— Control allows system to

operate at full capacity under low ambient temperature

conditions.

FAN CYCLING — These 38AH units have standard pro

vision for fully automatic intermediate-season head pres

sure control through condenser fan cycling. Fan no. 2 is

cycled by an outdoor-air thermostat which responds to out

door ambient temperature. The thermostat is loeated in the

lower divider panel between the compressor compartment

and condenser section. Through a hole in the panel, the

sensing element is exposed to air entering the no. 1 fan

compartment. Fan no. 1 is non-cycling. Table 5 shows the

operating settings of the air temperature switch.

Table 5 — Fan Cycling Controls

CONTROL BY

SWITCH OPENS

SWITCH CLOSES

Temp — F (C)

60 ± 3 (15 6 ± 1.7)

70 ± 3 (21.1 ± 1.7)

NOTE: See Fig. 6 for fan arrangement.

20