Carrier 38AH024-034 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

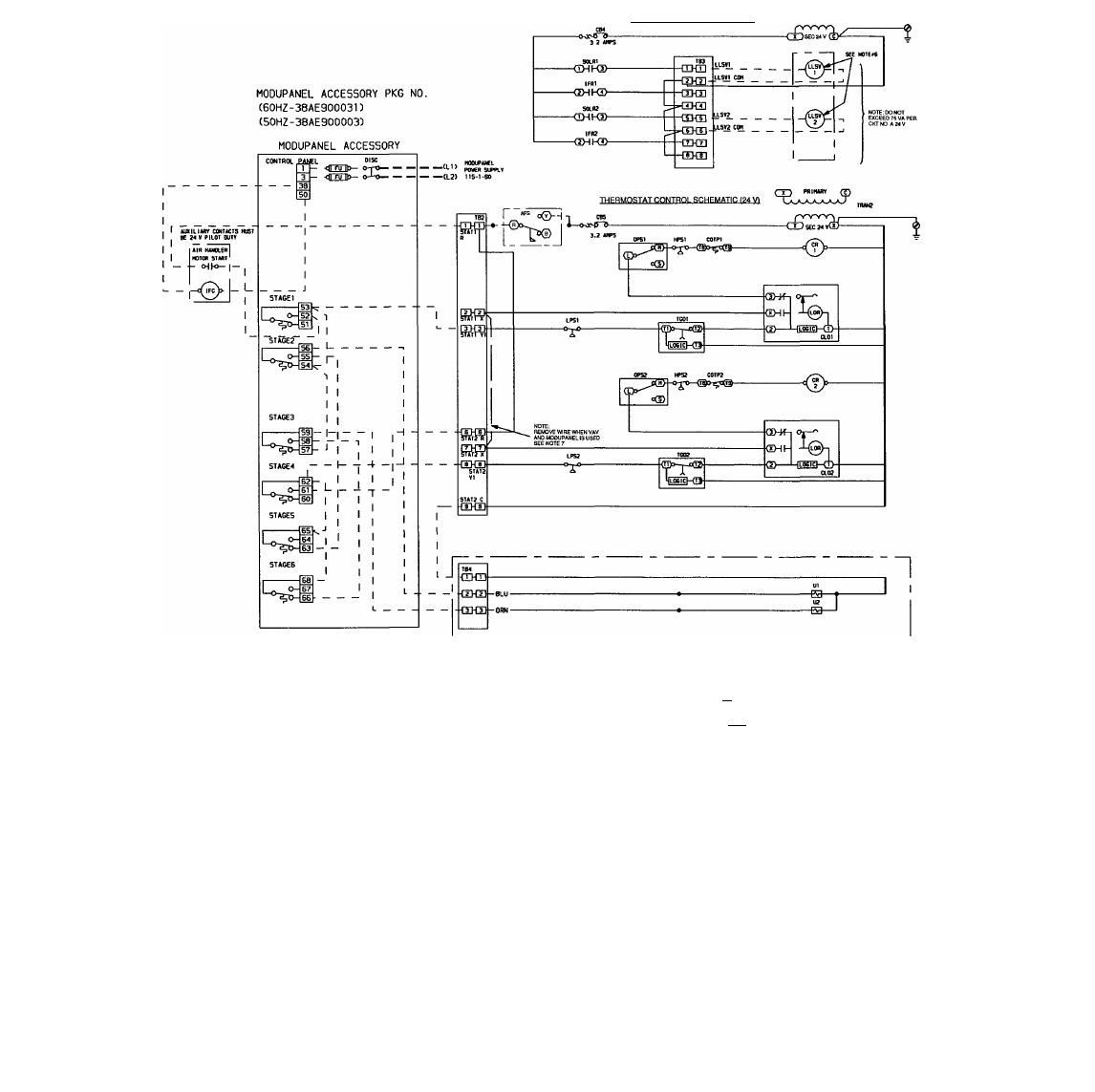

LLSV CONTROL SCHEMATIC 124 VI

AFS

— Airflow Switch

LLSV

C

— Contactor, Compressor

LOR

CB

— Circuit Breaker

LPS

CLO

— Compressor Lock-Out

OPS

COM

— Common

PL

COTP

— Compressor Overcurrent Protection

SOLR

CR

— Control Relay

STAT

DISC

— Disconnect

TB

HPS

— High-Pressure Switch

TGD

IPC

— Indoor-Fan Contactor

TRAN

IPR

— Indoor-Fan Relay

U

kcmil

— thousand circular mils

VA

LLS

— Liquid Line Solenoid

VAV

LEGEND

Liquid Line Solenoid Valve

Lock-Out Relay

Low-Pressure Switch

Oil Pressure Switch

Plug Assembly

Solenoid Relay

Thermostat

Terminal Block

Time Guard® Device

Transformer

Unloader (Solenoid)

Volt-Ampere

Variable Air Volume

I I Terminal Block Connection

^—>

Marked Terminal

O

Unmarked Terminal

Unmarked Splice

Field Accessory Wiring

Factory Wiring

Field Control Wiring

Field Power Wiring

Indicates Common Potential;

Does Not Represent Wiring

Factory wiring is in accordance with National Electrical Code (NEC)

(U.S A. Standard) Field modifications or additions must be in com

pliance with all applicable codes

Wiring for field power supply must be rated 75 C minimum. Use

copper, copper-clad aluminum, or aluminum conductors Maxi

mum incoming wire size for main terminal block (TB1) is 350 max

kcmil (230 v). All other voltages 2/0 AWG (American Wire Gage)

maximum

Terminal blocks TB2, TB3, and TB4 are for external field control

connections Control connections are to be class 2 wiring.

Field-supplied components connected to TB3 (e.g., LLS1 and

LLS2) cannot exceed 75 va total inductive load at 24 vac, so that

NOTES TO FIG. 9 AND 10

TRAN1 does not become overloaded The air handler auxiliary

motor starter contacts must have a minimum rating of 30 va at

24 vac The airflow switch must have minimum contact rating of

125 va at 24 vac.

5. Replacement of factory wires must be with type 105 C wire or its

equivalent

6. Field-supplied liquid line solenoid valves installed at the evapo

rator are required on circuits no. 1 and 2 on all units

7.

ModuPanel control is wired for one air handler only Re

move wire between TB2-2 to TB2-7 for ModuPanel control

applications

Fig. 9 — Typical Wiring Schematic — VAV ModuPaner

One Dual-Circuit Condensing Unit with Air Handler

12