Conductivity, Calibration conductivity – YSI ProDSS User Manual

Page 37

35

Calibration

Conductivity

A conductivity/temperature sensor must be installed on the bulkhead for accurate temperature compensation and

measurements of all other parameters (

). Temperature calibration is not available or required for

accurate temperature measurements.

The conductivity/temperature sensor can measure and calculate conductivity, specific conductance (temperature

compensated conductivity), salinity, non-linear function (nLF) conductivity, TDS, resistivity, and density. Calibration

is only available for specific conductance, conductivity, and salinity. Calibrating one of these options automatically

calibrates the other conductivity/temperature parameters listed above. For both ease of use and accuracy, YSI

recommends calibrating specific conductance.

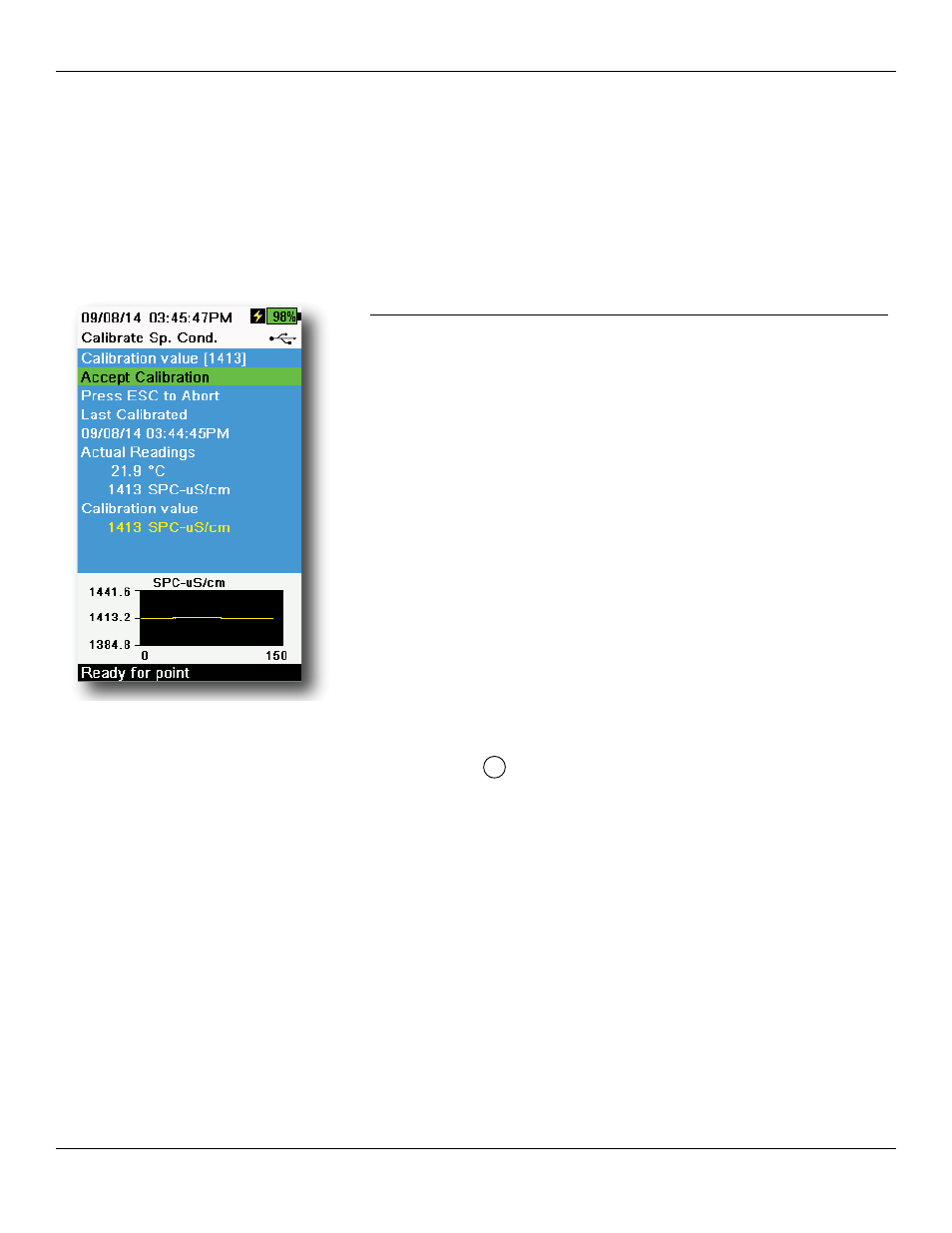

Figure 45 Calibrate specific

conductance

Conductivity calibration

1. If necessary, clean the conductivity cell with the supplied soft

brush. See

Conductivity/temperature sensor maintenance on

2. Perform the

Calibration setup (pH, ORP, ISE, conductivity, turbidity)

3. Place the correct amount of conductivity standard (225 mL if using

the calibration cup) into a clean and dry or pre-rinsed calibration

cup.

NOTE: Select the appropriate calibration standard for the

conductivity of the sampling environment. Standards

greater than 1 mS/cm (1000 μs/cm) are recommended for

the greatest stability. For fresh water applications, calibrate

to 1,000 or 10,000 uS. For salt water applications, calibrate

to 50,000 uS.

4. Carefully immerse the sensors into the solution. Make sure the

solution is above the vent holes on the side of the conductivity

sensor.

5. Gently rotate and/or move the sensor up and down to remove any

bubbles from the conductivity cell. Allow at least one minute for

temperature equilibration before proceeding.

6. Push the

Cal

key, select Conductivity, then select Specific

Conductance.

NOTE: Calibrating any conductivity calibration option will

automatically calibrate the other options. Specific

conductance is recommended for both ease of use and

accuracy.

7. Select Calibration value then enter the calibration value of the

standard used. Note the measurement units the instrument is

reporting and calibrating and be sure to enter in the correct

calibration value for the units being used. For example, 10,000 uS

= 10 mS. Make sure that the units are correct and match the units

displayed on the handheld.

8. Observe the actual measurement readings for stability (white line

on graph shows no significant change for 40 seconds), then select

Accept Calibration (

). “Calibration successful!” will be

displayed in the message area.