VACUUBRAND PC 600 LAN NT User Manual

Page 78

page 78 of 102

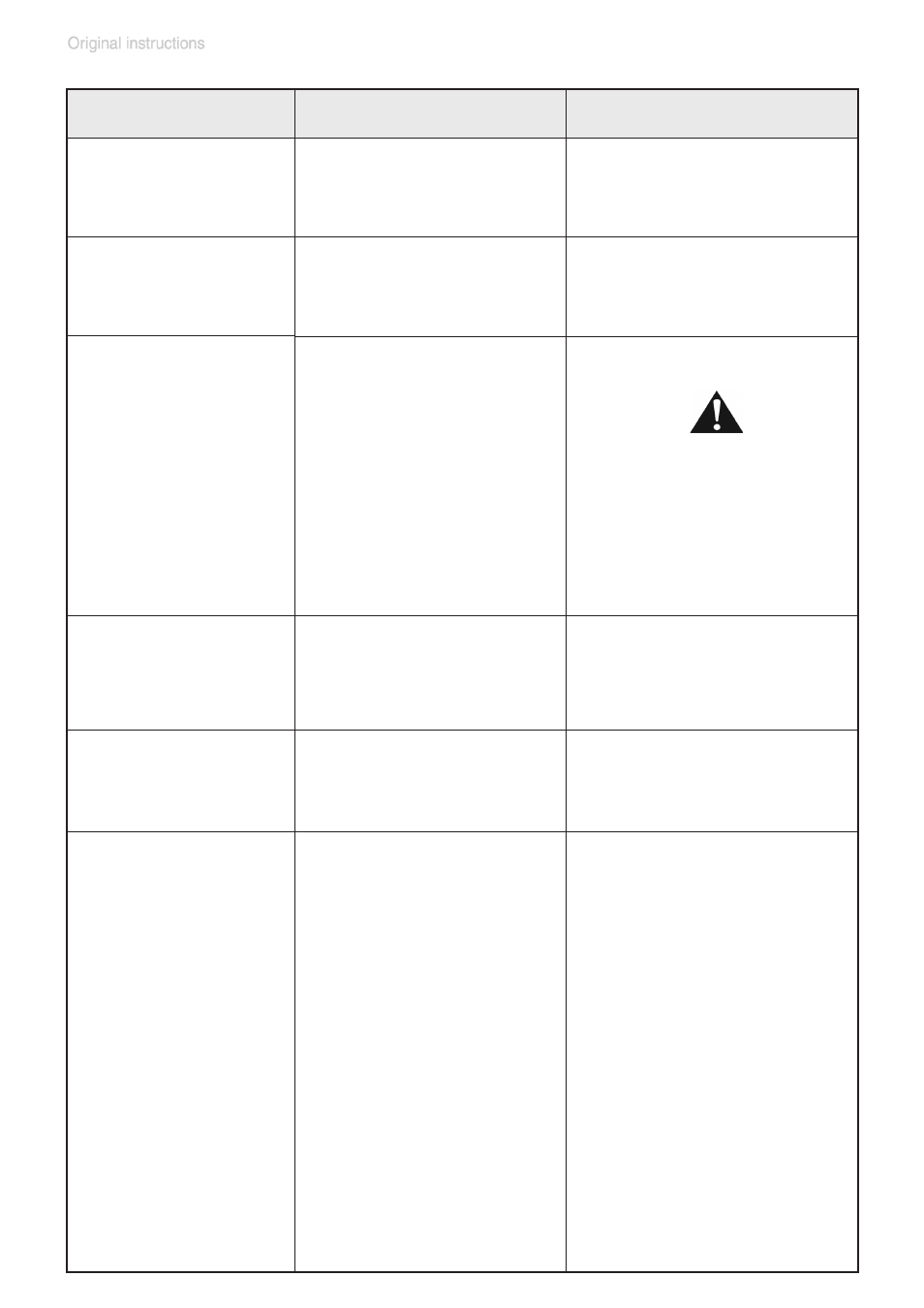

Fault

Possible cause

Remedy

❑ Error message

”ErrValve”, three

blips*.

➨ In-line valve removed

or defective?

✔ Connect or check valve or

replace with a new one or

reconfigure without valve.

Switch VNC 2 off/on.

❑ Error message

”ErrValve”, four

blips*.

➨ Coolant valve removed

or defective?

✔ Connect or check valve or

replace with a new one or

reconfigure without valve.

Switch VNC 2 off/on.

❑ Error message

”p Error”, five

blips*.

➨ Overpressure at the

pressure transducer,

pressure > 810 Torr

(1080 mbar)?

✔ Release pressure imme-

diately (risk of bursting).

➨ External pressure

transducer VSK 3000

removed or defective?

✔ Plug in or check external

pressure transducer or

use a new one or recon-

figure without VSK 3000.

Switch VNC 2 off/on.

➨ Internal pressure trans-

ducer defective?

✔ Contact local distributor.

❑ Error message

”ErrTemp.”, seven

blips*.

➨ Excess temperature?

✔ Check configuration and

process parameters.

➨ Relay circuit defective? ✔ Contact local distributor.

❑ Error message

”CheckSys”, eight

blips*.

➨ Switch-off time is not

reached within the pre-

set time of process?

✔ Check system for leaks.

Check process time.

Select suitable pressure

value ”p set”.

❑ Error message

”ext. Err”, nine

blips*.

➨ Level sensor has been

set off?

✔ Drain catchpot. Message

disappears. In case, re-

start process.

➨ Level sensor has been

removed?

✔ Connect level sensor

again or reload a factory-

set basic mode.

➨ External fault indicator

has been set off?

✔ Eliminate external error.

➨ External fault indicator

has been removed?

✔ Connect external fault

indicator again or switch

controller off/on.

➨ Emission condenser

EK Peltronic has been

removed?

✔ Connect EK peltronic

again or switch controller

off/on.

➨ Excess temperature at

condenser EK Peltron-

ic? Process stopped?

✔ Allow condenser EK Pel-

tronic to cool down. In

case, restart process.