TriangleTube Prestige Cascade System User Manual

Page 30

27

SECTION VI – SYSTEM PIPING

Multiple Distribution Manifolds

The maximum number of boilers that can be piped in

series is five. If installing more than five boilers you will

need to install the boilers in banks of no more than 5 boil-

ers per bank. The multiple banks should only consist of

Primary Secondary Cascade Kits to ensure adequate flow

through boilers. The system piping between these boiler

banks should be piped in parallel, see Figure 29, page 31.

The parallel system piping between banks may require a

balancing valve(s) if installing an uneven number of boil-

ers per bank (i.e. 4 boiler bank, with a 2 boiler bank), see

Figure 30, page 32.

System Piping

The system piping must be a “closed” system to

avoid any oxygen contamination and potential fail-

ure of the Cascade.

1. The minimum recommended system iron pipe size is

listed in Table 9. This table provides the individual

boiler and system flow rates at various system tem-

perature differences. This table also lists system pip-

ing pressure drops per 100 feet of system piping.

2. To determine the system pressure drop, calculate

the total equivalent length (T.E.L.) of pipe for each

valve and fitting in the system piping in the appro-

priate pipe size using Table 10 page 28. Add the

T.E.L. to the actual straight length of system pipe

of the same size.

3. Once you have calculated the T.E.L. of system pipe

based on a specific pipe size, multiply it by the pressure

NOTICE

drop/100 feet listed for the pipe size to establish the total

circuit pressure drop for that pipe size. If using various

pipe sizes in the system, you will need to do this calcula-

tion for each pipe size separately and add the total pres-

sure drops of all sizes to get a total system pressure drop.

When sizing the system piping and components, it’s

recommended to use a minimum flow rate of 11 gpm

per Solo 250 boiler or 19 gpm per Solo 399 boiler in the

cascade to limit the flow velocity to 4 feet/second and

the friction loss (pressure drop) to 4.2 feet/100 feet of

pipe. Size system piping and components using

approved/recognized design methods, if necessary con-

tact Triangle Tube Technical Support for assistance.

It is recommended to utilize a primary/secondary

Cascade when the total system flow rate is greater

than 22 gpm per Solo 250 boiler or 38 gpm per Solo

399 boiler or less than 11 gpm per Solo 250 boiler or

19 gpm per Solo 399 boiler. A primary/secondary

Cascade is also recommended when the system flow

rate and pressure drop are unknown.

See Figure 31, page 33 for P/S Cascade system piping.

See Figure 32, page 34 for R/R Cascade system piping.

To avoid potential contamination of the boiler piping

and heat exchangers. Install optional strainer kit,

PSCAS24 on the system return piping to boilers in any

R/R Cascade application (with or without boiler valves).

NOTICE

BEST PRACTICE

NOTICE

CSD-1 Piping & Control Installation

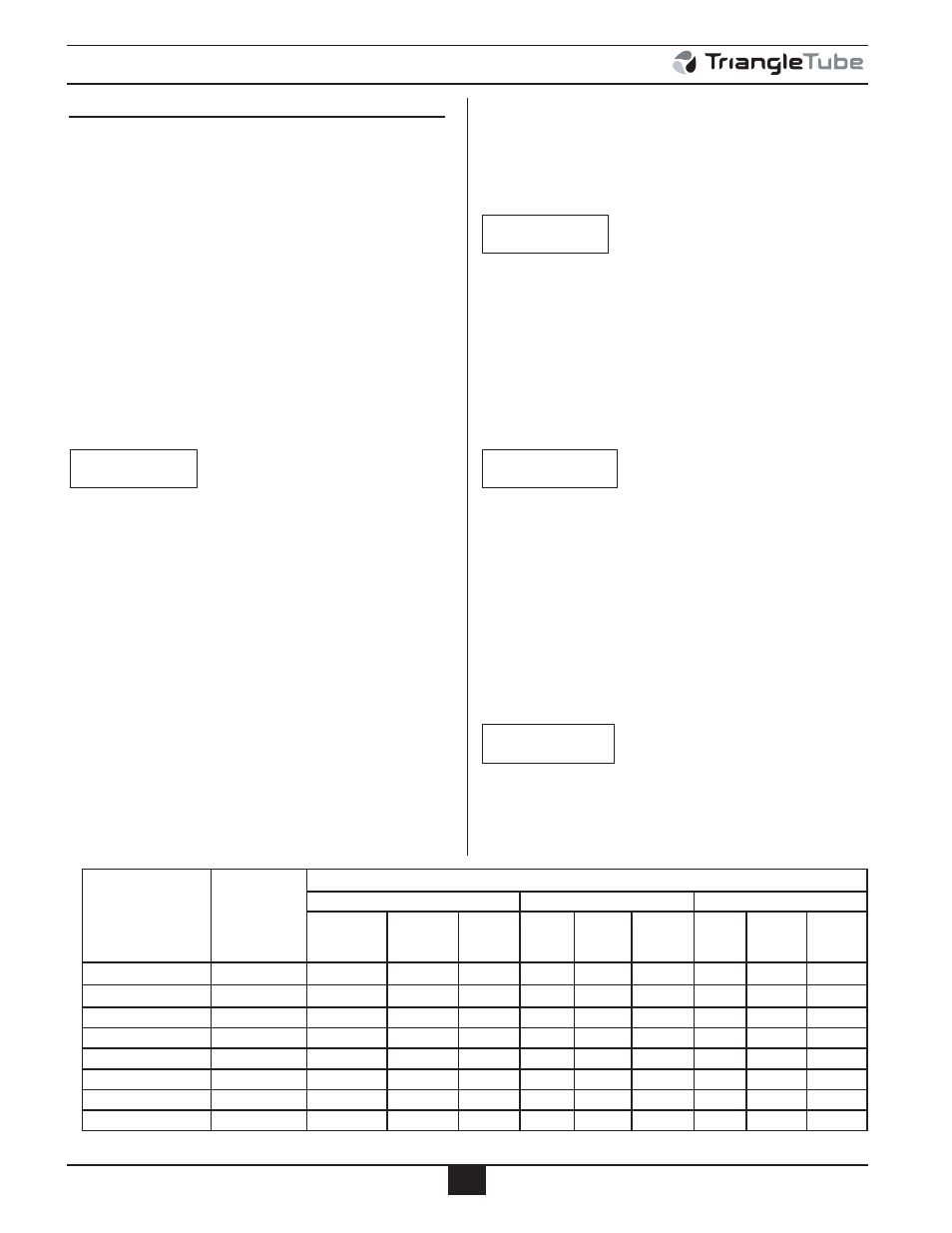

Table 9: Minimum Recommended System Iron Pipe Size and Pressure Drop/100 Feet of Pipe

Individual Boiler

or Cascade Kit

P/N

Total Output

MBH

System Temperature Difference (F)

20

30

40

GPM

Iron Pipe

Size

∆P/100

Feet

GPM

Iron

Pipe

∆P/100

Feet

GPM

Iron

Pipe

∆P/100

Feet

Solo 250

223

22

1.5”

3.4

15

1.25”

3.5

11

1.25”

2.0

Solo 399

379

38

2”

2.8

25

1.5”

4.2

19

1.5”

2.6

C(PS or RR)500

446

45

2”

3.5

30

2”

1.8

22

1.5”

3.4

C(PS or RR)800

758

76

3”

1.4

51

2.5”

1.9

38

2”

2.8

C(PS or RR)1000

892

89

3”

1.9

59

2.5”

2.5

45

2”

3.5

C(PS or RR)1200

1,138

114

4”

0.8

76

3”

1.4

57

2.5”

2.5

C(PS or RR)1600

1,518

152

4”

1.4

101

3”

2.5

76

3”

1.4

C(PS or RR)2000

1,897

190

4”

2.1

126

4”

1.0

95

3”

2.2