Top Flite KittiWake User Manual

Page 9

3. Use a sanding block to smooth each side of these

surfaces. Remove the two elevator halves and

rudder from their die-cut sheets. Lay the stabilizer

on your flat work surface and pin or weight in

place. Use a strip of clear protective material

(food wrap) to line the trailing edge of the stab.

Position the two elevator halves firmly against

the trailing edge of the stab and pin or weight in

place. From your parts bag, locate the 2-1/2" length

of 3/16"dia. dowel, this is the elevator joiner. Epoxy

this dowel in place in the slot provided in each

elevator half and allow to cure.

4. Remove the now joined elevators from your

bench. Lightly sand the leading edge of the

elevators smooth and flat. Now use masking tape

to accurately attach the elevators to the stab, on

one side only. Turn this assembly over and use a

sanding block to sand the leading edges, tips and

trailing edges to about halfway to the cross-

sections shown on the plans. Now tape the

elevators to the stab on the sanded side, turn the

assembly over, remove the tape and repeat the

sanding procedure just described. The fin and

rudder are match-sanded in the same manner.

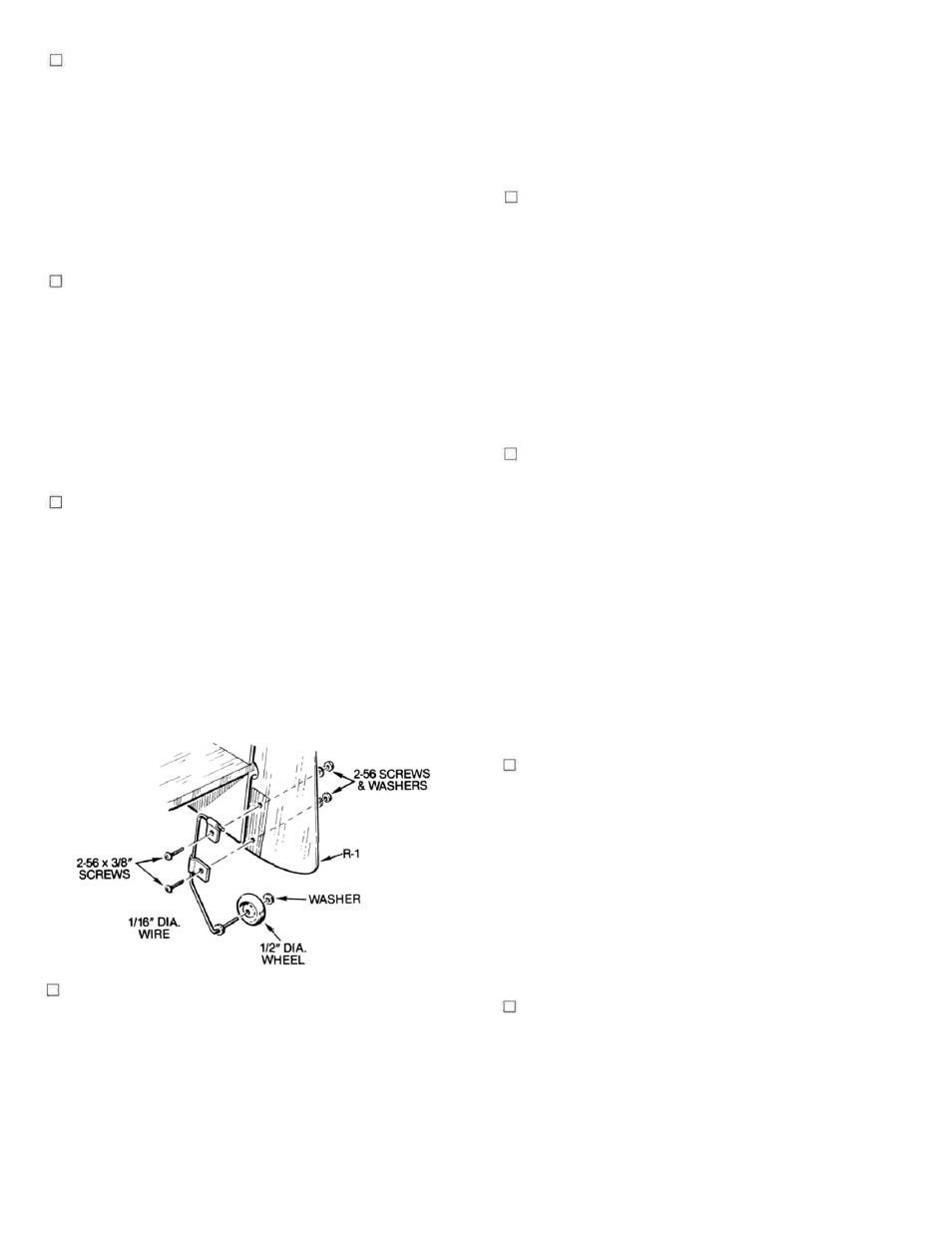

5. Locate and remove the two R-2 parts from their

die-cut sheet. As shown on the plans, these are

meant to provide a hard-point at the bottom,

leading edge of the rudder for mounting the water

rudder or tail wheel. Lightly sand the edges of

these parts smooth. Lay one of the R-2 parts in

place on the rudder and trace it's outline on the

rudder with a pencil. Use a single-edge razor

blade to now cut out a 1/16" deep inset location for

the R-2 part. Repeat this operation on the other

side of the rudder. Once satisfied with the fit,

epoxy the two R-2 parts in place. Weight or clamp

this assembly and allow to cure.

6. As shown on the plans, the leading edges of the

elevators and rudder are beveled to facilitate

movement. Use a sanding block to now bevel

these two parts. Now use the plans to locate and

mark the hinge locations on the elevators, stab,

fin and rudder. Carefully cut the hinge slots in

each of these surfaces and trial fit them

together—do not glue hinges in place yet. Once

satisfied with the fit of these parts to each other,

use a sanding block to match them to each other

while hinged in place.

1. From your kit, locate and remove from their die-

cut sheets, the following parts; F-1 (fuselage

sides, 2), F-3 (nose doublers,2), F-2 (fuselage

doublers, 2) and the light-ply fuselage formers,

F-5 and F-6. Tape or hold the two fuselage sides

together and use your sanding block to match

edges. Lay one of the fuselage sides directly over

the side view on the plans and carefuly mark the

locations (top and bottom) of the firewall, F-5, F-6

and the 1/4" sq. balsa bracing (@D-D). Use a

straight edge to now draw these locations direct-

ly on the fuselage side. Repeat this operation on

the other fuselage side (remember, you need a

RIGHT and LEFT side).

2. With the fuselage sides laying flat on your bench,

glue the F-3 nose doublers in place. Now lay the

F-2 fuselage doublers in place, being careful to

match the wing saddle area. Observe the fit in

relationship to the lines you drew earlier. If

necessary, trim the doublers to fit precisely. Once

satisfied, glue the F-2 part in place, weight or pin

and allow to dry. From your kit, locate the four re-

quired lengths of 1/4" triangle balsa stock. Cut, fit

and glue the triangular fuselage longerons in

place, top and bottom. Cut, fit and glue the four re-

quired lengths of triangular stock to the top and

bottom of the F-3 doublers and finally, glue

triangular stock in place, directly beneath the

stabilizer slots. With the fuselage sides still down

flat on the bench, cut, fit, and glue the 1/4 " sq.

balsa uprights in place (see D-D).

3. At this point, you may wish to start planning your

radio installation by placing one of the servos on

the fuselage side, marking its location on the

wood for later placement of servo rails or servo

rail braces.You may alsowishtoplotouttheeven-

tual location of the throttle pushrod. Next, make

sure that you can pass the fuel tank you're plann-

ing to use through the opening in former

F-5—route out as needed to accomplish this. The

last thing to do before joining the fuselage sides

is to bevel each side, at the tailpost, to provide a

nice fit when the sides are pulled together (see

top view of plans).

4. Trial-fit F-5 and F-6 in place on each of the

fuselage sides; dress them with the sanding

block if needed to achieve a nice fit. Lay the right

fuselage side down flat on the bench and glue F-5

in place using a triangle to make sure that it is

perpendicular. Repeat this process with F-6. App-

ly glue to the other side of these two formers and

position the left fuselage side to them. Turn the

structure upside down on your bench and pin or

weight in place—allow to dry.

FUSELAGE CONSTRUCTION

A review of the plans and cross-sections reveals that the

fuselage construction is basically the typical box-type

which, when completed, lends itself to rounding. Before

starting, you should have available to you the radio

system that you plan to use and the engine, tank and

motor-mount.

9