Top Flite KittiWake User Manual

Page 12

the back of the spinner 1/32" from the front of F-4.

This is the position that your engine should be for

drilling the holes in the motor mount. Mark these

engine lug holes now, on the motor mount with a

pencil or scribe. Remove the engine, spinner and

motor mount. Accurately drill the four required

holes in your motor mount (Note: For .25-sized

engines, we suggest using #4-40 socket head

bolts and tapping the motor mount for #4-40

threads.). Reassemble the mount, engine and

spinner to check for accuracy of fit. With

everything still in place, positioning of the two

fuel line holes (fuel feed and muffler

pressure/overflow venting) and the throttle

linkage should be noted on the firewall for drill-

ing. The last thing to make provision for is the fit-

ting of your engine's muffler with sufficient

clearance. Do this now.

Remove all of the above components from the

front of your fuselage. Using a longer drill bit of

the correct (never oversize) diameter to the fuel

tubing and throttle linkage housing, drill the

holes marked earlier through the firewall. It is at

this point that we suggest a coat of polyester

resin be given to the inside of the engine compart-

ment and firewall (don't get any in the holes for

the motor mount). We also like to use resin inside

of the tank compartment and on the rear face of

F-5.

19. Use the same method described in the TIP FLOAT

ASSEMBLY section to accurately cut the molding

base off of the canopy. Next, securely tape a

sheet of #220 sandpaper over the area that the

canopy is to be mounted on the fuselage. Careful-

ly sand the base of the canopy to conform to the

top of the fuselage (it won't take much since the

fuselage, at this point, is only slightly rounded).

Once the canopy fits, hold it in place exactly

where you want it to be, and use a soft pencil to

draw its outline on the fuselage. If you wish, as we

did, to add cockpit detail, now is the time. We us-

ed a Wm. Brothers pilot head, suitably cut-down

to fit, scraps of black construction paper and a

few instrument decals we had laying around to

make a reasonable-looking cockpit. Once

satisfied, the canopy can be glued in place to the

fuselage with a slow-setting CA glue—tape or

hold and allow to set.

20. There are some good fillet materials currently on

the market which we have used and recommend;

Penn's "Pie N' Patch" and Model Magic Filler.

Use the one that you're most comfortable with to

now apply a small fillet around the canopy (tape it

off with electrical tape) and around the

fin/fuselage, stabilizer/fuselage and sub-

fin/fuselage joints. You should also lookoveryour

fuselage carefully for any nicks, dings or voids

and fill these at this time. Once the filler has set,

use a light grade of sandpaper to smooth these

out. You should now cut the last required hinge

slot in the rear edge of R-3 for rudder attachment.

FINAL ASSEMBLY

I. MAIN FLOAT ASSEMBLY

Back in the construction of the fuselage (Step 13), you

drilled the two required mounting holes in each of the

two unbent aluminum float legs. The float legs must

now be accurately bent to provide fit and attachment to

the main float and the plywood "hardpoints" built into it.

Take a look at the cross section shown on the plans of

this fuselage/float leg/main float relationship. You can

see that the float legs must be bent equally on each side

and that, at the bottom, they are bent slightly once again

to pick-up the vertical float sides. In all of this, the

fuselage/float relationship must provide for a.) proper

propeller clearance (9" dia. max prop size) and b.) the

correct angle of attack for the wing/fuselage/engine

combination.

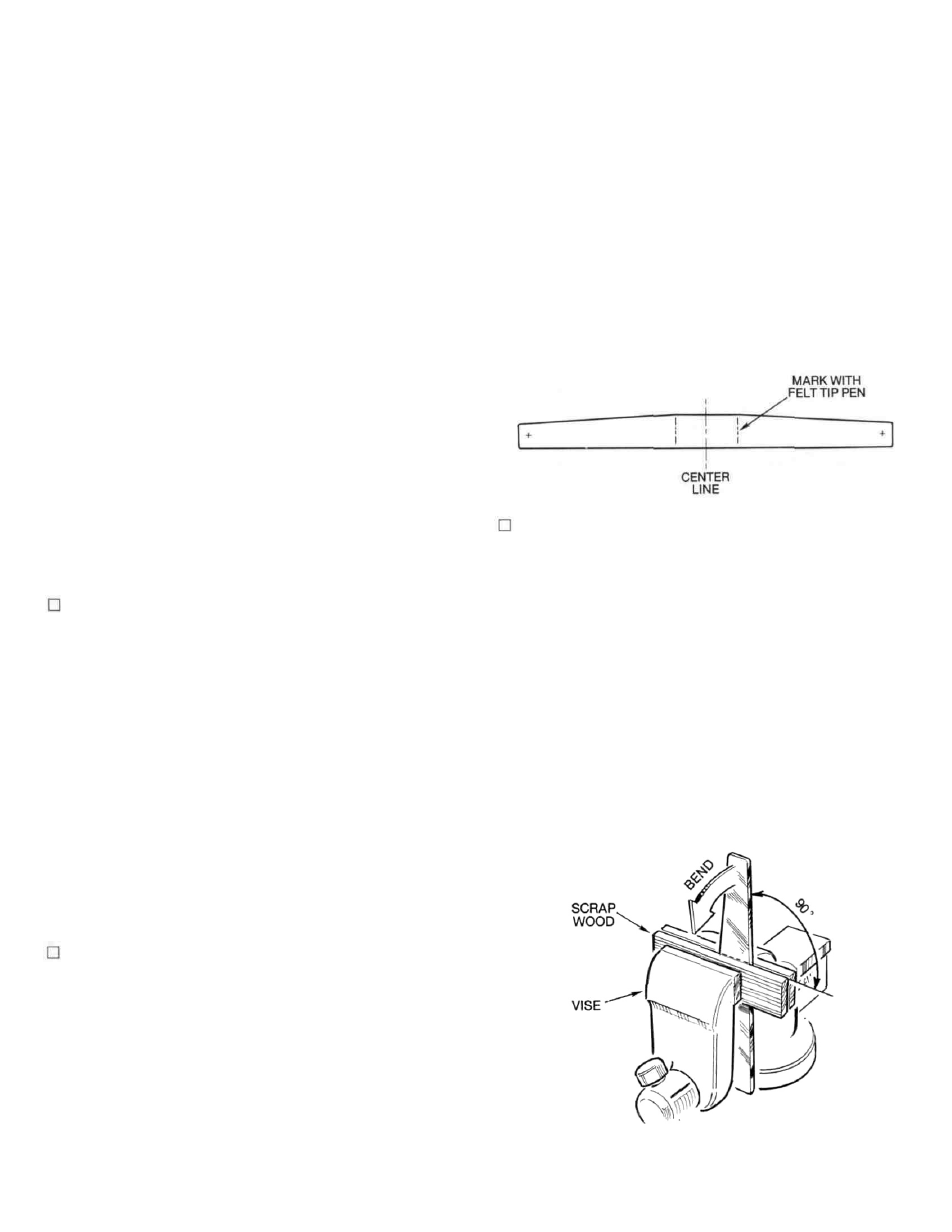

1. Hold the float leg, straight edge down, vertically

in place on your flat bench. With a triangle and

scribe (sharpened nail will do) mark two vertical

lines on the float leg, each 1 -1/4" on either side of

the centerline that you marked earlier. This pro-

vides you with an accurate 2-1/2" inside bending

location. Place the float leg into a vice with a

piece of hardwood on each side of it (see

diagram) and make the first bend directly along

the line just marked on the part. This bend is made

by "eyeballing" the drawing provided. Turn the

part over and make the second bend. Remove the

part, lay it over the drawing to check for how close

you came. Continue this process until the part

matches the drawing. Repeat this procedure for

the other float leg.

12