Top Flite KittiWake User Manual

Page 6

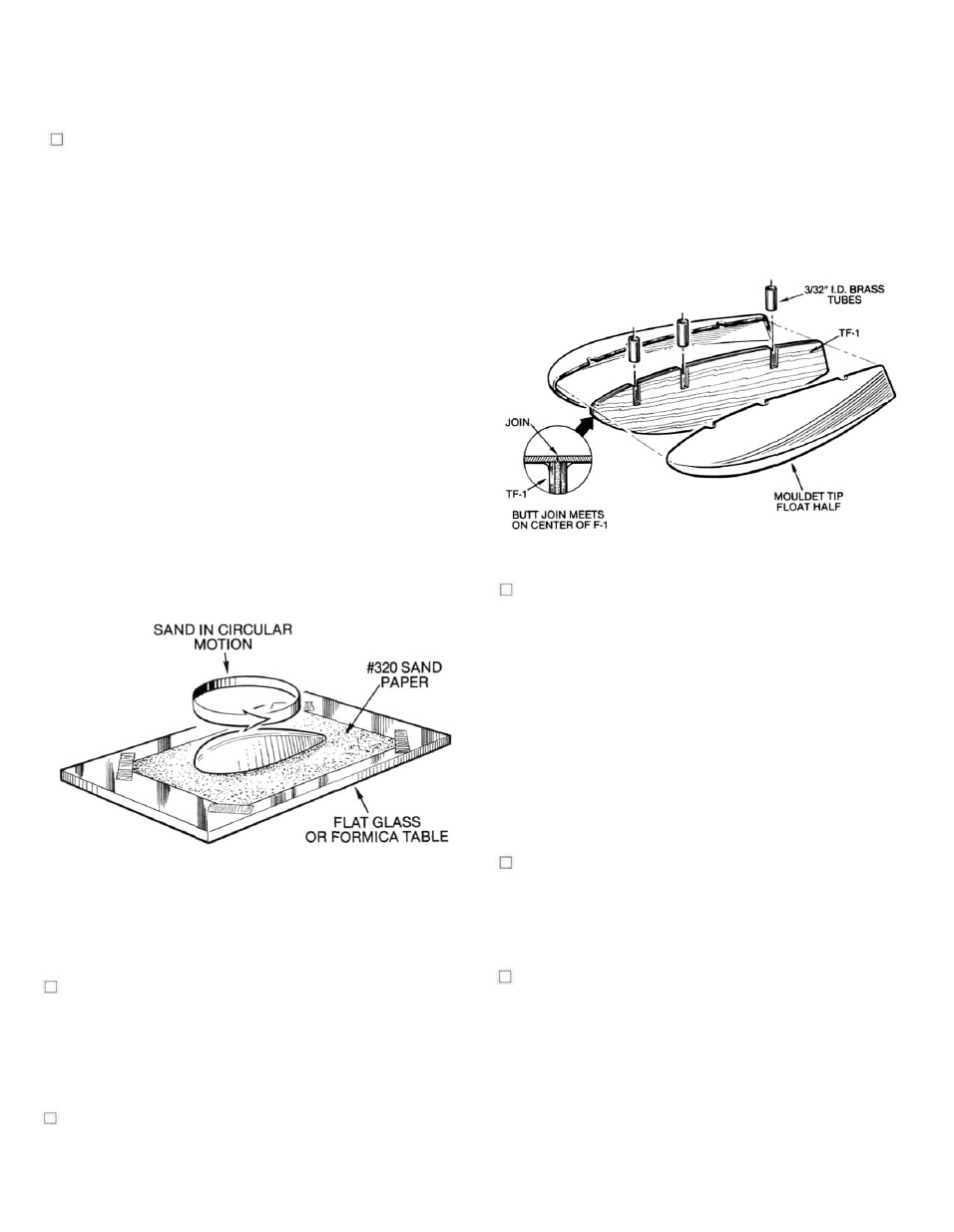

1. As shown in the cross-section diagram, the tip

float has to be cut from it's base. The easiest way

to do this with absolute accuracy is to make a sim-

ple cutti ng tool. We use a 4 "-5" length of 1/8" x 3/8"

spruce or hard balsa to which we glue a #11 X-acto

blade, flat, to one end of this stick with about one

half of the blade's length protruding past the end

of the stick. When this tool is laid flat on the

bench, it can provide a consistently accurate cut

1/8" above the work surface. Use a flat formica

table top for this operation. Select one of the tip

float halves and place flat on the table and hold it

firmly to the table with one hand. With your other

hand, slide the X-acto tool all around the tip float,

scoring it lightly as you go. Repeat this operation

several times until you have a definite score line

all around the piece. You should now be able to

flex the plastic at the score line until it breaks

free. Repeat this procedure with the remaining

float halves.

halfway into the center—take your time to

achieve a good fit. Once satisfied, locate the six

required lengths of brass tubing from the parts

bag in your kit. Lay the TF-1's flat on a protected

work surface and epoxy one of the tubes into each

of the slots provided. Be sure the tubes are laying

flat and that glue does not get into them and allow

to cure completely. When dry, lightly sand the

tops of these tubes flush with the top edges of the

TF-1 cores.

tubes provide mounting capability to the wing. The

secret to success here is the accurate cutting of the tip

float halves from their bases, thus providing a nice,

straight edge at the center.

2. As shown, the edges of each tip float should now

be sanded lightly to absolute flatness. A piece of

#320 sand paper taped to a piece of glass or a for-

mica table top will work great for this purpose.

Simply hold the tip float half on the sandpaper

and move it lightly in a circular motion. Just a few

passes will be needed.

3. Locate and remove the two required TF-1 light-ply

cores from their die-cut sheet. These cores now

need to be final sanded to fit exactly into the

center of the tip float halves. They only need to fit

4. In this step you are going to glue the TF-1 cores

halfway into one of the tip float halves. We sug-

gest using a slow-setting CA adhesive for this

operation. Use your finger to apply a liberal

amount of glue around the inside center edge of

the tip float half. Now carefully insert the TF-1

core halfway into the float half and lay the

assembly down on your protected work surface

(core side down) and allow to cure. Once the glue

has set, pick up the assembly and inspect it for

any glue runs, etc. These can be quickly removed

with a single edge razor blade. Once satisfied,

trial fit the other float half in place—it should fit

accurately, even if a little pressure is required to

do so. Remove the remaining unglued half.

5. Use a 3/32" dia. drill bit to carefully open up the

ends of each of the brass tubes. The remain ing tip

float half can now be glued in place. Again apply

glue all around the inside center edge of the part

and press it in place. Tape or hold the assembly

until cured.

6. Once again use the 3/32" drill bit to clear-out the

holes in the brass tubes. The now-assembled tip

floats should be lightly sanded along the center

joint with #320 paper to true them. Some filling

may be required along this joint and for this we

would suggest something like lacquer putty (pro-

bably the best choice), available at most

automotive paint supply outlets. On our pro-

totypes, we used both PIC's "Pie N' Patch" filler

and Model Magic Filler with great results. Finally,

we suggest wet-sanding the floats with #600

paper prior to painting. These floats can be

6