Full size dihedral gauge forw1-a&w1-b – Top Flite KittiWake User Manual

Page 3

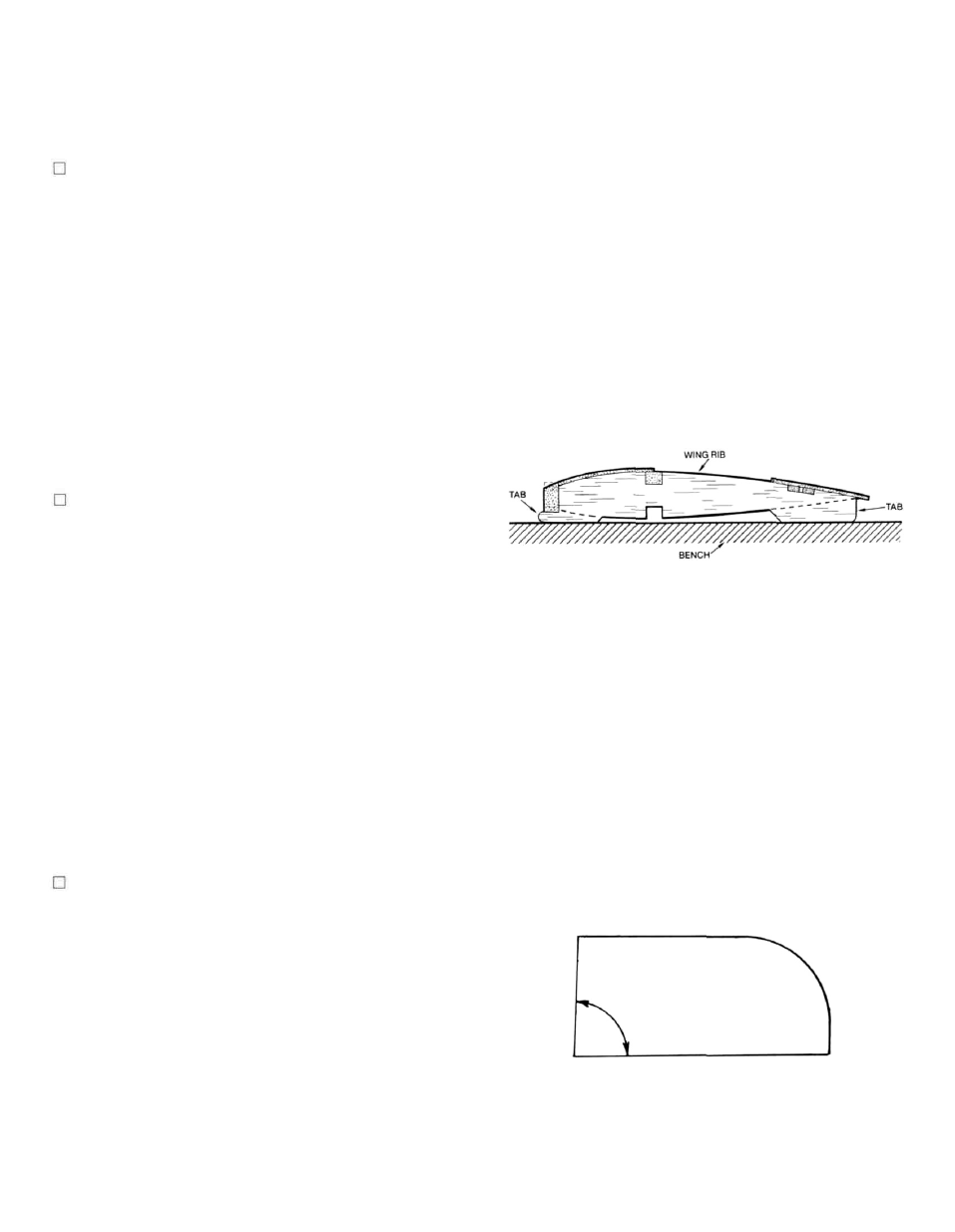

1. From their die-cut sheets, carefully remove all

wing ribs, W-1 (A and B) through W-8. Where

necessary, use a #11 blade to free the parts, mak-

ing very sure that bottom tabs remain attached.

(These have been partially cut through for later

removal, should one break off, reattach it with a

spot or two of glue). If needed, lightly sand the

edges of the ribs to remove any burring. Locate

and remove die-cut (ply) parts W-9 and W-10. Addi-

tionally, locate and have ready the four 1/

4 " x 3/8"x

24"wing spars, the two 3/8 x 3/4" x 24" leading

edges and the two 1/8" x 1/4" x 36" sub spars—all

balsa. Of course, as we proceed with these in-

structions, you will need wing sheeting

(1/16"balsa) from the stock provided in your kit.

Protect your plans with clear food wrap or

MonoKote® backing. We will build the center

section first, followed by the outer panels.

2. Cut two 2 11/16" lengths of 1/4" x 3/8" spar stock (Im-

portant: cut one of these lengths from one piece

of spar stock and the other piece from a different

length of spar stock). From one of the leading

edge pieces, cut a 2-11/16" piece. Accurately pin one

of the spar pieces directly over the plans. Now

securely pin the two rear W-1 B's in place against

the spar, making sure that they are perfectly ver-

tical to your work surface (use a triangle or block

to be sure). Now set the W-9 dihedral brace in

place on the work surface, against the bottom

spar and the two W-1 B's. Like the W-1 B's, ac-

curately position and securely pin the forward

W-1A's in place against the W-9 brace. With the

above securely in place, glue the 2-11/16" piece of

leading edge stock to the front of each W-1A (do

not glue to the break-away tabs). Now carefully

glue the top length of spar stock in place to the

W-1 B's. Starting from the leading edge, cut, fit

and glue all of the center-section's 1/16" balsa

sheeting in place; allow to dry.

3. Carefully remove this assembly from your work

surface. Unpin the short length of spar stock from

your work surface. Turn the assembly over and

epoxy W-10 in place against the rear face of the

leading edge and up against the top sheeting.

Carefully glue W-9 in place against the W-1A's and

B's, the top spar and sheeting. Take care here to

wipe-off any excess adhesive on the outer sur-

faces of the ribs and W-9. Glue the remaining

length of spar stock in place against W-9 and to

the W-1 B's. Carefully remove the bottom rib tabs

from each rib section and use a sanding block to

smooth the bottom of this structure as well as

bevel the bottom rear edge of the top sheeting.

From the kit, locate the shaped basswood wing

bolt insert. As shown, this part fits in place be-

tween the W-1 B's, about 3/8" ahead of the trailing

edge. Sand the insert as needed to fit and when

satisfied, epoxy in place. The bottom of this struc-

ture is now sheeted with 1/16" balsa from the

leading edge back to the trailing edge. Do this ac-

curately and neatly. Use a small sanding block to

now smooth the rib/sheeting joints, keeping the

outer surfaces of W-1A and B flat.

(Note: The following outer wing panel construc-

tion steps assume that both the left and right

panels are built simultaneously. Also, this is the

point at which your decision about installing the

landing gear option, shown on the plans, should

be made. The patterns provided on the plans for

rib reinforcement parts RR-1 through RR-3 should

be used to make the 1/16" Ply parts and these

should now be epoxied in place to the concerned

ribs.)

4. Use the full cross section of the wing, the view

directly beneath the wing plan, to now accurately

cut and bevel the top and bottom 1/4" x 3/8" spars

and the

3/8"x3/4"

leading edges. You'll note that the

inboard W-1 ribs are angled to provide the needed

7/8" dihedral for each wing panel. In order to pro-

vide this angle uniformly to each W-1 rib section,

we've provided you with a dihedral guage, shown

here. Use this as a pattern to now makethis guage

from either scrap ply or balsa. As you did for the

center section, now pin the bottom spars ac-

curately in place over the plans. Take care here to

ensure that they are in place straight. These bot-

tom spars are only in place for accurate rib align-

ment at this time.

FULL SIZE

DIHEDRAL GAUGE

FORW1-A&W1-B

sells a pre-bent, tempered aluminum landing gear that

mounts directly to the fuselage, at the forward float leg

location. Ken Willard has used this variation quite suc-

cessfully (see RCM Magizine, November, 1986). The

following instructions assume the float plane version

only.

3