Top Flite KittiWake User Manual

Page 7

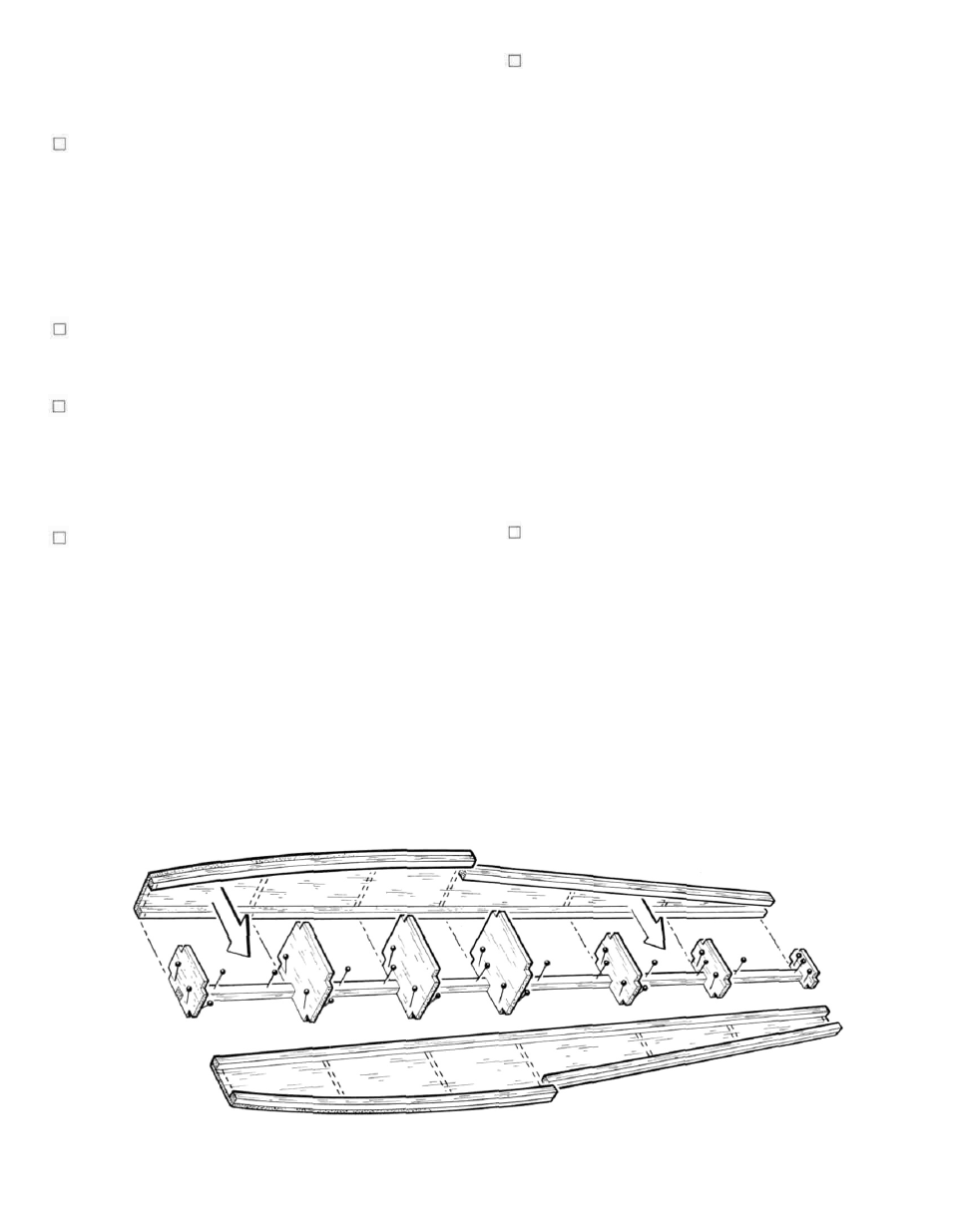

1. Locate and remove the two FL-1 main float sides

from their die-cut sheets. Tape or pin these ac-

curately together and use a sanding block to light-

ly sand their edges smooth. Now lay one of the

FL-1 parts directly over the side view of the main

float on the plans. Use a soft pencil to accurately

mark the position of each float former—top and

bottom. Use a straight edge to draw the former

locations directly onto the FL-1 part. Do the same

thing to the remaining FL-1 part.

2. Using the 1/4" sq. balsa stock provided in your kit,

glue the top and bottom longerons in place to

each FL-1 float side—REMEMBER, you want a

LEFT and a RIGHT float side!

3. Locate and carefully remove the seven required

float formers (FL-2 through FL-8) from their die-

cut sheets. Now trial-fit each former in place

against each of the FL-1 float sides. Use a single

edge razor blade to make any adjustments re-

quired to achieve a good fit to the float sides and

the 1/4" sq. longerons.

4. As shown, the main float is built upside down,

directly over the plans. Start by accurately posi-

tioning and pinning in place the 1/4 " sq. balsa

"former locator" directly over the centerline on

the top view of the main float. We'd suggest using

along straight edge to be certain that this piece is

straight. Starting with the forward FL-2 former, ac-

curately glue each former in place to the 1/4" sq.

former locator making sure that each former is 90°

upright from your work surface; a triangle is

helpful here. Securely pin each former in place.

5. In this step you are going to glue the float sides in

place to the formers (still pinned and positioned

overthe plans). You will need to use a slow-drying

adhesive to allow you time to work. We suggest

the slowest setting CA-type adhesive you can find

or something like 15-30 minute epoxy. Before

glueing, trial-fit the sides to the former assembly

to be sure that everything fits as it should. While

doing this, experiment with bending the float

sides to fit the formers at both ends to get some

idea of the amount of pressure required. If there

seems to be too much pressure needed to do this,

a little common household ammonia, wiped or

sprayed on the float sides, helps the wood to

bend. Assuming that you are satisfied with the fit,

you can start to glue the FL-1 sides in place. We

suggest starting by applying glue to the inside of

each FL-1 (using the pencil marks made earlier)at

the FL-5 through FL-8 former locations. Working

quickly, position each FL-1 side in place to each

former; securely pin and/or weight as needed.

Now apply glue to the FL-4 through FL-2 former

locations drawn on the FL-1 sides and bend the

sides around these three forward formers. Again,

securely pin and/or weight as needed. Allow this

assembly to dry completely.

6. Carefully unpin and remove the float assembly

from your work surface. Use a sanding block to

now smooth the top and bottom. You can also

make a few passes with the sanding block on

each of the sides. Now carefully sand the front of

former FL-2 to render it flush with the sides. Do

the same thing to the rear FL-8 former. Once

satisfied, the front and rear balsa blocks can be

glued in place. These two blocks are now shaped

to conform to the top and side views, shown on

the plans, with the exception of the tops of each

block, leave these flush with the float sides for

now.

painted with a variety of available paints,

preferably sprayed. Our choice is K&B epoxy.

MAIN FLOAT CONSTRUCTION

7