Top Flite TOPA0220 User Manual

Page 37

❏

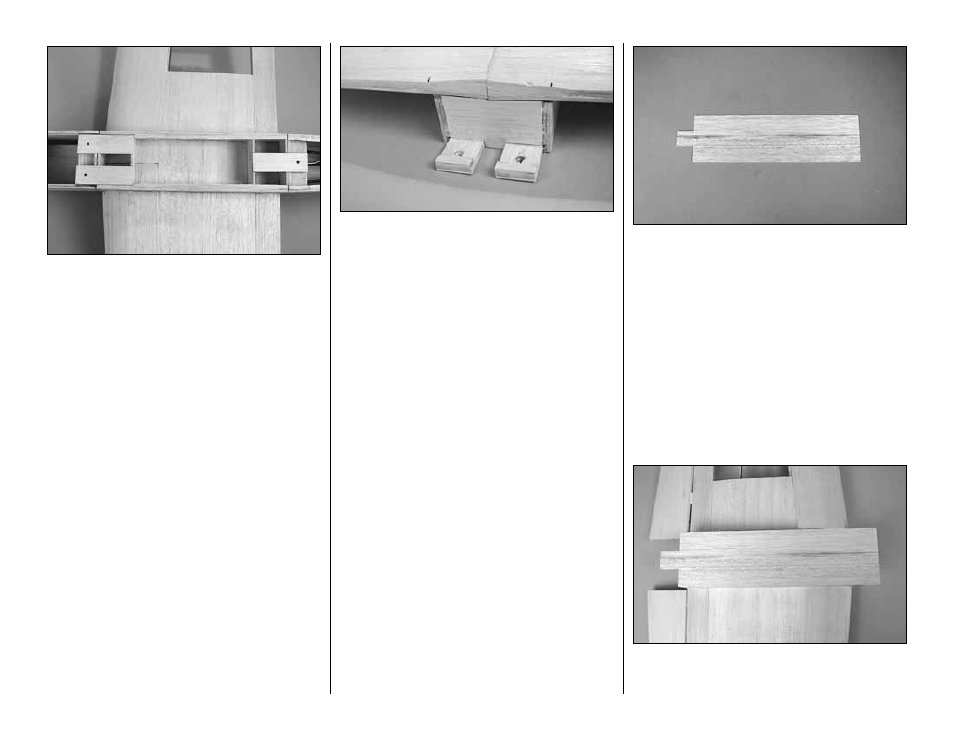

13. Reposition the wing on the fuselage making

sure it fits properly and that the belly pan sides are

even with the fuselage sides. Drill a tap hole for the

1/4-20 nylon bolts in the three wing hold down

blocks. Drill the holes at the pin point punch marks.

The holes go through the wing hold down blocks and

also through the fuse hold down blocks under them.

❏

14. Remove the wing from the fuselage. Drill the

holes in the

wing hold down blocks ONLY with a 1/4"

[6.4mm] drill bit. Harden and fuel proof the area with

some thin CA.

❏

15. Tap the holes in the fuse hold down blocks with a

1/4-20 tap. Harden the tapped holes with a few drops of

thin CA. When the CA cures tap the holes again.

❏

16. Cut the three 1/4 -20 x 2" [51mm] nylon bolts

to a length of 7/8" [22.2mm]. This is necessary to

clear the fuel tank.

❏

17. From a leftover 1/8" x 1/4" [3.2 x 6.4mm]

basswood stick cut three pieces 1" [25.4mm] long.

Glue these pieces to the ends of the wing hold down

blocks as shown in the photo.

Note: When the wing is mounted there is a 1/8"

[3.2mm] gap between the wing hold down block and

the fuse hold down block. This allows the 1/4-20

wing bolts to flex a bit should you catch a wing tip on

landing. The 1" [25.4mm] sticks stop the wing hold

down blocks from being deformed when the wing

bolts are tightened.

❏

18. Install the control linkage on the flap servo.

Plug the flap and elevator servos into the receiver,

turn the transmitter on and temporarily plug a battery

into the receiver. Mount the wing to the fuselage and

check the clearance of the flap servo and linkage

with the other servos and linkages in the fuselage.

Operate the flap servo throughout the full range of

motion. If there are any conflicts you may need to

shorten the flap joiner arm slightly. Remove the wing

from the fuselage and unplug the battery and flap

servo. Turn the transmitter off.

If you are installing an electric motor on the model

for power, you will want to build a battery access

hatch in the belly pan. If you are installing a glow

engine then just skip the steps for the hatch and

glue the bottom sheeting into place.

❏

19. Locate the two die-cut 3/32" [2.4mm] balsa belly

pan sheeting parts. Use your bar sander to sand the

edges flat and straight where the parts join. Edge glue

both parts together using either thin CA or aliphatic

resin. Align the parts even at the front edges. Use your

bar sander with 150-grit sandpaper to sand the

assembled belly pan sheeting flat and smooth.

❏

20. Glue the belly pan sheeting to the bottom of

the belly pan with medium CA. Drill 1/4" [6.4mm]

holes through the sheeting for the wing bolts.

-37-