Build the elevators – Top Flite TOPA0220 User Manual

Page 11

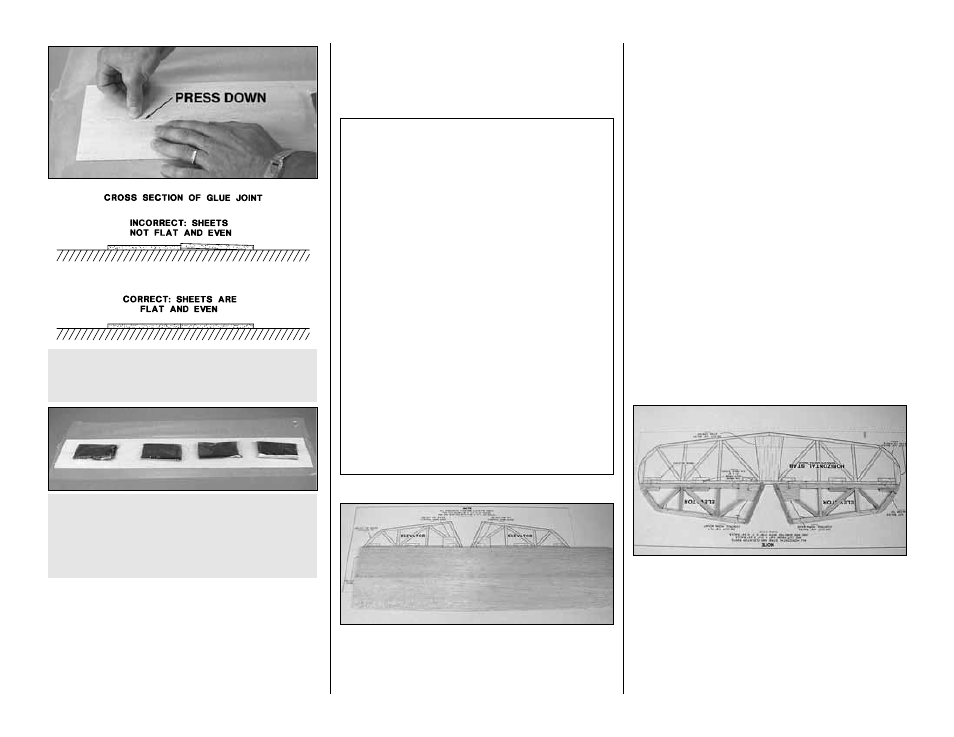

Note: Some modelers tend to sand the sheeting too

much after it is applied to the structure, making thin

spots where fingers can easily go through. By

following the procedure above (specifically, by aligning

the joined edges of the sheets as shown in step E),

little sanding should be required. Most of the sanding

that

is required should be done before the sheeting is

glued in place. The only sanding that should be

required after the sheeting is glued to the structure is

final sanding with 320 or 400-grit sandpaper.

❏

8. Use medium CA or aliphatic resin to glue the

stab skin to the top of the stab. Align the skin even

with the TE of the stab. Note that the sheeting is

positioned so that it overhangs one end of the stab.

❏

9. After the glue dries, remove the stab from the

building board and trim the sheeting along the LE

and both tips. Save the leftover sheeting for use in

the next step.

❏

10. Locate another hard sheet of 1/16" x 3" x 24"

[1.6 x 76 x 610mm] balsa. Use this sheet and the

leftover sheeting from the above step to make

another stab skin.

❏

11. Turn the stab over and use a sanding block to

sand the un-sheeted side of the stab flat. Use

medium CA or aliphatic resin to glue the stab skin to

the stab. Align the skin even with the TE of the stab.

The sheeting is positioned so that it overhangs one

end of the stab.

❏

12. After the glue dries, remove the stab from the

building board and trim the sheeting along the LE

and both tips. Save the leftover sheeting for use in a

later step.

BUILD THE ELEVATORS

❏

1. Pin the die-cut 1/8” balsa control horn base

into position. Use 1/8" x 1/4" x 24" [3.2 x 6.4 x

610mm] soft balsa sticks to cut all of the parts for

both elevators. Pin them into position and glue the

parts together with thin CA where they join.

❏

2. After the CA has cured, remove the pins from

both elevators. Use a sanding block with 150-grit

sandpaper to sand the elevators flat.

Here are a few other things to keep in mind

while sanding balsa sheeting:

1. Make sure you sand the sheets on a flat work

surface that is free from hardened drops of glue or

other imperfections that will damage your

sheeting.

2. Sand the sheeting only as much as required.

The inside of the sheeting needs to be sanded just

enough to remove excess glue and doesn’t have

to be perfectly flat or smooth.

3. Though more material can be removed by

sanding across the grain, this leaves scratches in

the balsa. Balsa sheeting should be sanded with

the grain—especially when finish-sanding.

4. If some of the glue joints are uneven, it may be

best just to leave them that way, rather than to

sand the sheets too thin. A slightly uneven glue

joint is preferable to paper-thin balsa.

F. Place weights on top of the sheet to hold it flat

while the glue dries.

G. After the glue dries, sand the sheets flat

and even.

E. Press the joining edges of the sheets down to

make sure they are even. This is important. Little

sanding will be required if the sheets are even.

-11-