Top Flite TOPA0220 User Manual

Page 27

front of each rib with thin CA. The top of the leading

edge should be even with the tops of the ribs. Use a

straight edge along the sides of W1 and W10 to

insure that they are straight.

Note: You will need to carefully sand the front of W2,

W3 and W4 at an angle to match the sweep of the

LE if those ribs have a ply doubler installed.

❏ ❏

22. Use your bar sander with 150-grit sandpaper

to lightly sand the top of the leading edge to blend it

evenly with the tops of the ribs.

❏ ❏

23. Using medium CA, glue one of the leading

edge skins that you prepared in step 2 into place on

the ribs and the top spar. The skin should extend

forward from the center of the spar. Refer to the

HOT

TIP that follows.

Note: Make sure you glue the skin in place with the

smooth side facing out. Position the 1/2" [12.7mm]

strip that was glued to the sheeting at the spar.

❏ ❏

24. Remove the wing panel from the building

board. Glue the wing skin to the tapered leading

edge with thin CA. Checking from the bottom of the

wing panel, insure that the leading edge skin is

securely glued to the tops of all the ribs.

❏ ❏

25. Carefully check all of the glue joints

between the spar web, top and bottom spars and the

wing ribs. Fill in any glue joints that don’t look solid

with thin CA.

❏ ❏

26. Trim the leading edge, leading edge

sheeting, spars and trailing edge even with W1 and

W10. Trim the leading edge sheeting even with the

front of the tapered leading edge.

❏ ❏

27. Snap the bottom of the TE spar/jig off even

with the bottom of the ribs. The TE spar/jig has an

embossed cut line where it is to be snapped off. OK,

so you got too much CA on the TE spar/jig when you

glued the ribs in place. Use a razor saw to cut along

the embossed line.

Important: Use caution not to break any of the short

jig tabs off of the top of the TE spar/jig.

❏ ❏

28. Use your sanding bar to sand the bottom of

the tapered leading edge even with the bottom of the

ribs, following the contour of the ribs. Do not change

the shape of the ribs. Also sand the trailing edge, TE

spar/jig and bottom spar even with the ribs.

❏ ❏

29. Turn the wing panel upside down and place

it on your building board. Pin the TE spar/jig to the

board and use weights to hold the front of the wing

panel on the building board.

Retracts go to step R33.

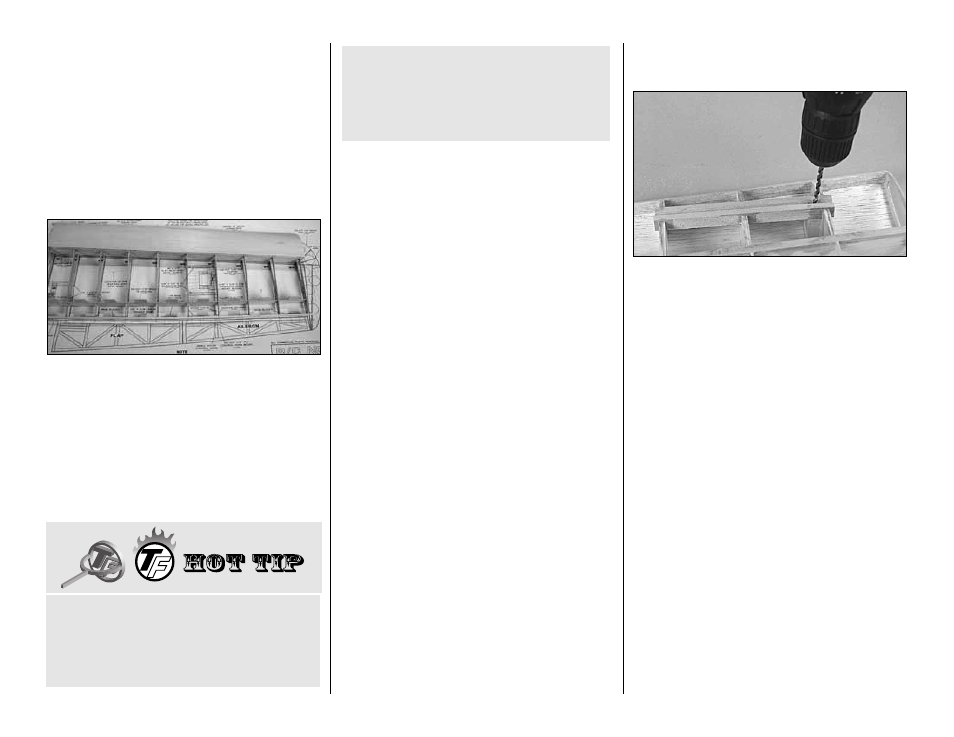

Use the following photo for the next two steps.

❏ ❏

F30. If you are installing fixed landing gear on

your model, glue the 7/16" x 5/8" x 5-5/8" [11.1 x

15.9 x 142.9mm] basswood grooved landing gear

rail into the notches in W2, W3 and W4 using

6-minute epoxy. The groove in the rail should face the

bottom surface of the wing. Glue the 7/16" x 5/8" x

7/8" [11.1 x 15.9 x 22.2mm] maple torque block to

the top surface of the rail against W2, as shown on

the plan.

Note: Before gluing the rail in place check the fit of

the rail in the notches. The rail should protrude 1/16"

[1.6mm] from the bottom of the ribs so as to be level

with the 1/16" [1.6mm] balsa sheeting when the

wing is sheeted.

❏ ❏

F31. Mark the bottom of the groove in the

landing gear rail 3/16" [4.8mm] from the edge of W2.

Drill a 5/32" [4mm] hole through the landing gear rail

and the torque block at the mark. As you drill, make

sure you hold your drill at a 90 degree angle to the

landing gear rail.

Note: The hole should go into the middle of

the torque block. Be careful not to drill through the

top skin.

After you remove the wing from the building

board, use thin CA to glue the skin to the tapered

leading edge. Working one section at a time

between two ribs, hold the skin to the tapered

leading edge and wick in some thin CA. Firmly

hold the skin in place until the CA cures.

It can be difficult to get a tight glue joint between

the leading edge skin and the tapered balsa

leading edge while the wing panel is still on the

building board. Do not apply any CA to the

tapered leading edge until after you remove the

wing from the building board in the next step.

-27-