Top Flite TOPA0220 User Manual

Page 32

❏ ❏

6. From a 1/16" x 3" x 24" [1.6 x 76 x 610mm]

balsa sheet cut two pieces to a length of 11"

[279mm]. Use medium CA or aliphatic resin to glue

one piece to the top of the flap. Align the skin even

with the LE of the flap.

❏ ❏

7. After the glue dries, remove the flap from the

building board and trim the sheeting along the TE

and both tips.

❏ ❏

8. Turn the flap over and use a sanding block

to sand the un-sheeted side flat. Use medium CA or

aliphatic resin to glue the second skin to the flap.

Align the skin even with the LE of the flap.

❏ ❏

9. After the glue dries, remove the flap from the

building board and trim the sheeting along the TE

and both tips.

❏

10. Build a second flap starting at step 2 above. The

flaps are symmetrical so you can build the second one

over the same plan.

❏

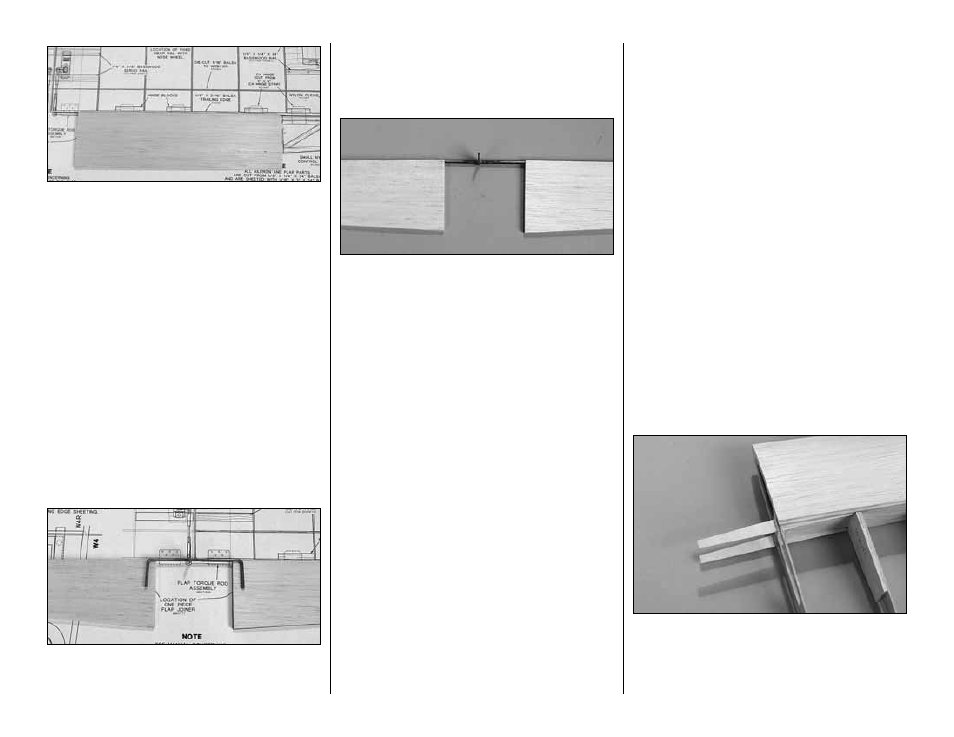

11. Use a file or a rotary tool with a cut-off wheel

to remove sharp edges or burrs on the ends of the

flap joiner. Position the flap joiner on the top of both

flaps as shown on the plan and in the photo. Mark

the leading edge of the flaps where the

arm portion

of the joiner will enter each flap. The center of the

hole will be about 3/8" [9.5mm] from the end.

❏

12. Drill a 1/8" [3.2mm] hole 1-1/4" deep into the

leading edge of both flaps at the mark you made. Be

sure to drill the hole on the centerline of the leading

edge. Cut a groove in the leading edge to

accommodate the flap joiner. If necessary, remove the

joiner and

tweak it so both flaps are in the same plane.

Hint: Use a 1/8" [3.2mm] brass tube sharpened at

one end to cut the groove.

HINGE THE AILERONS AND FLAPS

Hinge the ailerons and flaps in exactly the same

manner as you did the elevators and rudder.

❏

1. Use a straightedge to mark the centerline of the

ailerons and flaps as well as the TE of the wing with

a ballpoint pen. Mark the location of the hinge slots

on the ailerons, flaps and wing TE where shown on

the plan. Cut the hinge slots in the ailerons, flaps and

wing TE along the center lines with a #11 blade or

the Great Planes Slot Machine.

❏

2. Cut twelve hinges to a size of 3/4" x 1" [19 x

25.4mm] from the CA hinge strip. Snip the corners

off so they go into the slots easier.

❏

3. Test fit the hinges into the slots. If the hinges do

not slide into the slots easily, work your knife blade

back and forth in the slot a few times to provide

more clearance.

❏

4. Drill a 3/32" [2.4mm] hole, 1/2" [12.7mm] deep

in the center of the hinge slots. Use a rotary tool with

a 3/32" [2.4mm] drill bit or a carbide cutter for the

best results. Reinsert your knife blade to

clean out

the slot after you drill the holes.

❏

5. Test fit the ailerons and flaps to the wing with

the hinges. If any hinge slots are not wide enough or

are misaligned, make adjustments so the ailerons

and flaps accurately fit the wing.

❏

6. Bevel the leading edges of the ailerons and

flaps to a “V” as shown on the cross section of the

plan. Use the centerline on the leading edges as a

guide. Test fit the ailerons and flaps to the wing.

Note: Make sure you can obtain the control throws

indicated in the back of the manual. If you cannot,

increase the “V” on the leading edges.

DO NOT glue the hinges until the model has

been covered.

JOIN THE PANELS

❏

1. Locate both die-cut 1/16" [1.6mm] ply spar

joiners. Trial fit them in the right wing panel, cleaning

any excess glue that may be in the way. The joiner

should go all the way to W2. The angled edge points

to the front of the wing. DO NOT apply any glue.

-32-