Top Flite TOPA0220 User Manual

Page 15

❏ ❏

2. Use your bar sander to sand the edges flat

and straight where the parts join. Using one set of

parts, edge glue the upper fuselage side, front lower

fuselage side and rear lower fuselage side parts

together using either thin CA or aliphatic resin. Align

the front lower fuselage side even with the front of

the upper fuselage side. Align the rear lower

fuselage side even with the wing saddle cutout.

When the glue dries, use your bar sander with 150-

grit sandpaper to sand the assembled fuselage side

flat and smooth.

❏ ❏

3. Edge glue the three parts for the belly pan

side together and sand the completed assembly flat

and smooth.

❏

4. Return to step 2 and make a second set

of parts.

❏

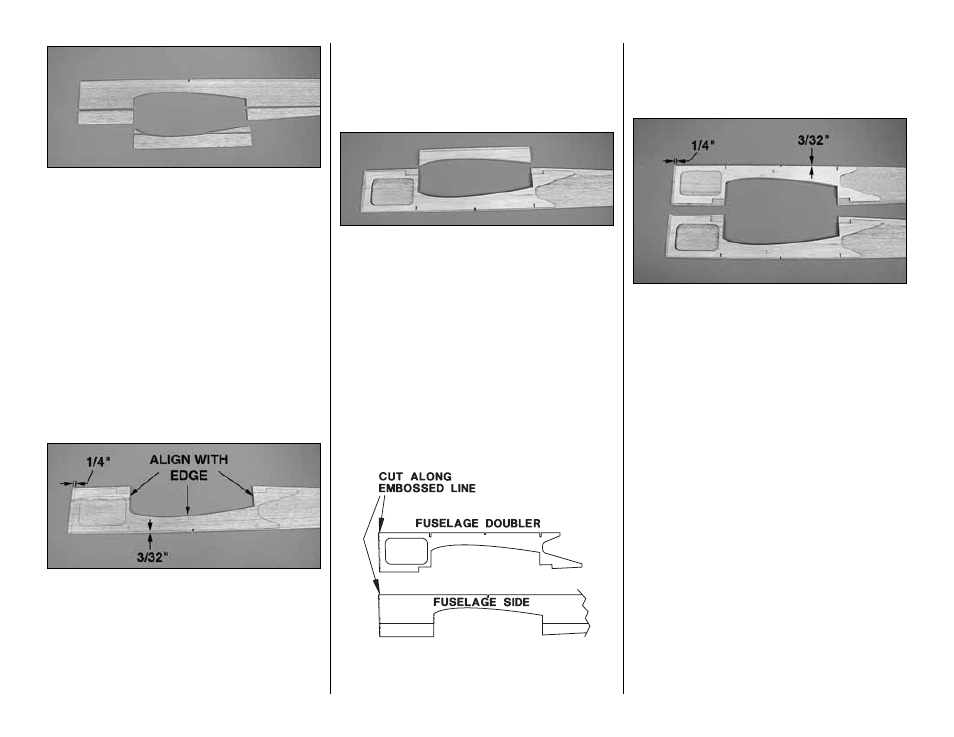

5. Position one of the sides on your building board

as shown in the photo. Position the die-cut 1/8"

[3.2mm] ply fuselage side doubler on the fuselage

side. Align the doubler with the wing saddle and

trace the outline of the doubler onto the fuselage

side with a ball point pen.

Note: It is important that the doubler be accurately

positioned on the fuselage side. Check that the

fuselage side extends 1/4" [6.4mm] beyond the

doubler at the front end of the assembly. Also check

that the fuselage side extends 3/32" [2.4mm]

beyond the doubler along the edge of the assembly

as shown in the photo.

❏

6. Glue the doubler to the fuselage side using

aliphatic resin glue or epoxy, aligning it accurately in

position. Do not use CA as it will not allow you to

reposition the parts. Use weights to hold the parts

together until the glue dries, making sure the parts

remain accurately positioned.

❏

7. When the glue has dried, remove the side from

the building board. Label this side “L”.

❏

8. Glue the belly pan doubler to the belly pan

side. Align the doubler with the wing saddle and with

the ends. The belly pan side should extend 1/4"

[6.4mm] beyond the doubler along the straight edge.

Label this assembly “L”.

❏

9. Locate the remaining fuselage side assembly and

fuselage side doubler. Note that the front edge of these

parts have an embossed cut line that is about 3/32"

[2.4mm] from the edge. Use a straight edge and your

knife with a sharp #11 blade to cut and remove the

material along the embossed line. This will establish the

proper right thrust for the engine.

❏

10. Position this side on your building board as

shown in the photo. BE SURE IT IS POSITIONED

AS SHOWN (unless you want two left sides)!

Position the die-cut 1/8" [3.2mm] ply fuselage side

doubler on the fuselage side. Align the doubler as

you did in steps 5 and 6 and glue it in position with

aliphatic resin or epoxy. Use weights to hold the

parts together until the glue dries, making sure the

parts remain accurately positioned.

Note: It is important that the doubler be accurately

positioned on the fuselage side. Check that the

fuselage side extends 1/4" [6.4mm] beyond the

doubler at the front end of the assembly. Also check

that the fuselage side extends 3/32" [2.4mm]

beyond the doubler along the edge of the assembly

as shown in the photo.

❏

11. When the glue has dried, remove the side from

the building board. Label this side “R”.

❏

12. Glue the belly pan doubler to the belly pan

side. Align the doubler with the wing saddle and with

the ends. The belly pan side should extend 1/4"

[6.4mm] beyond the doubler along the straight edge.

Label this assembly “R”.

Caution: Be sure you are building a right side, not

another left.

-15-