Top Flite TOPA0220 User Manual

Page 16

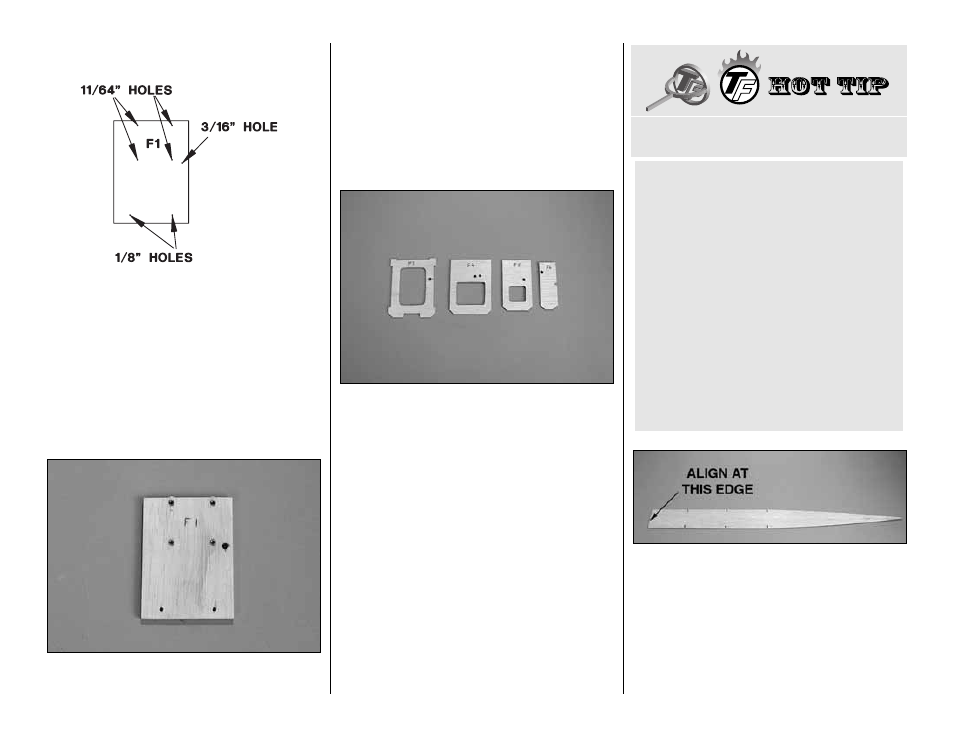

FRAME THE FUSELAGE

❏

1. Locate both die-cut 1/8" [3mm] ply F1 firewalls.

Glue them together using 6-minute epoxy.

Note: Make sure the pin point punch marks are

facing out on one side. Label this side F1.

❏

2. When the epoxy has cured drill 1/8" [3.2mm]

and 11/64" [4.4mm] holes where shown in the sketch

above. The 3/16" [4.8mm] hole is for the throttle

pushrod for an OS .46 FX.

❏

3. Install four 6-32 blind nuts in the 11/64" [4.4mm]

holes. Put some epoxy on the blind nuts as you install

them to hold them in place. Be careful not to get any

epoxy in the threaded holes in the blind nuts.

Note: The blind nuts are installed on the aft side of F1.

❏

4. Referring to the former drawings on the

fuselage plan, drill 3/16" [4.8mm] holes for the

pushrods in formers F2, F3, F4, F5 and F6 at the pin

point punch marks. Label the front of each former.

❏

5. Refer to the “pushrod exit locations” drawing on

the plan and the HOT TIP below. Drill 3/16" [4.8mm]

holes in the fuselage sides for the pushrods. The left

side has one hole for the rudder pushrod. The right

side has one hole for the elevator pushrod.

Note: The drawing shows where the holes should

enter and exit the fuselage sides on the inside and

outside. This allows you to judge the angle at which

the holes should be drilled.

❏

6. Locate the die-cut 3/32" [2.4mm] balsa left and

right fuselage top deck parts. Use your bar sander to

sand the edges flat and straight where the parts join.

Edge glue the left and right fuselage top deck parts

together using either thin CA or aliphatic resin. Align the

parts even at the front edges. Use your bar sander with

150-grit sandpaper to sand the assembled fuselage top

deck flat and smooth.

Note: The front edge is cut at a 2 degree angle to

establish the engine right thrust angle.

A. Mark the fuselage side with pins where the

hole enters and exits the fuselage side.

B. Start by drilling a 3/16" [4.8mm] hole at the

exit point on the outside of the fuselage side.

C. Turn the side over and use a rotary tool with a

cutoff wheel to cut a trough in the interior of the

fuselage side. The trough should extend from the

pin mark at the entry point to the hole you drilled

at the exit. MAKE SURE you are cutting the

trough on the inside of the fuselage side.

D. Dress the angled hole up by using the 3/16"

[4.8mm] drill at an angle and sliding it in and out

of the hole to shave the hole clean. Any

imperfections at the exit can be filled and sanded

after the pushrod is installed.

HOW TO DRILL ANGLED HOLES

-16-