Top Flite TOPA0220 User Manual

Page 35

❏

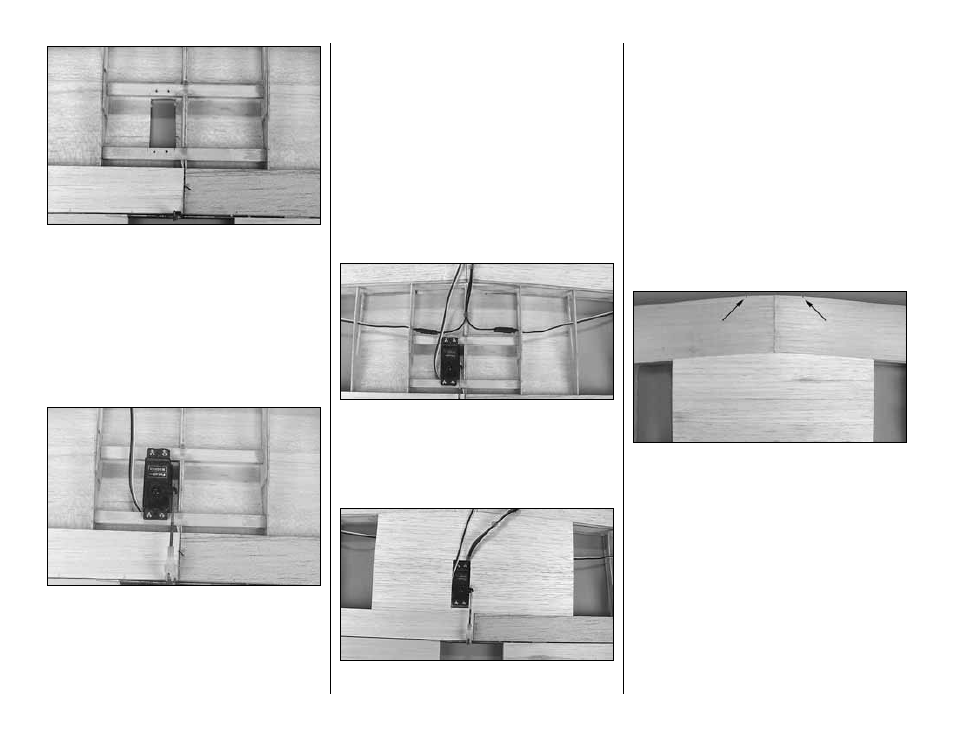

10. Using the FLAP SERVO MOUNTING

TEMPLATE as a guide, mark the location of the

basswood rails for the flap servo on the top of rib W1

and both W2 ribs. Fit the servo rails in the wing. The

rails extend from one W2 rib, across both W1 ribs, to

the other W2 rib. It will be necessary to notch the W1

ribs for the rails. The bottom sheeting must also be

cut to fit the servo as it will extend below the

sheeting. The top of the servo arm should be 3/8"

[9.5mm] above the top sheeting. Use the side view of

the fuselage as a guide in positioning the rails.

❏

11. Make a flap control rod from a nylon clevis,

clevis retainer and .074" x 6" [1.6 x 152mm] wire

threaded on one end. Install your flap servo on the

left side of the wing with the screws, grommets and

eyelets supplied with the servo. Install the flap joiner

in the flaps and fit the flaps to the wing. Connect the

joiner to the control rod you just made. With the flaps

centered and the servo arm at 90 degrees to the

servo, make a Z-bend in the control rod where it will

connect to the servo arm. Connect the control rod to

the servo arm. Note that the control rod is installed

into the top of the servo arm.

❏

12. Position the wing on the fuselage and check

the clearance of the flap servo and linkage with the

other servos and linkages in the fuselage. There

should be adequate clearance with no conflicts

between any of the servos and their linkages. Make

any adjustments needed now while you can still see

the servos and linkages. You may need to shorten

the flap joiner arm.

❏

13. Install 12" [305mm] servo wire extensions on

each aileron servo. Secure the connection with tape or

heat shrink tubing. Route the servo wires for each servo

through the wing ribs and out the flap servo area.

Note: For a neater installation, use short lengths of

fuel tubing to tie-wrap the servo wires together.

❏

14. Sand any epoxy that seeped from the joint

between the panels on the top of the wing. Remove

the flap linkage. Sheet the top center section using a

piece of 1/16" x 3" x 24" [1.6 x 76 x 610mm] balsa in

the same manner that you sheeted the bottom

center section, going from one W3 rib across the

center W1 ribs to the other W3 rib. Cut the opening

for the flap servo close to the servo. Otherwise, the

opening will extend beyond the fuselage side.

FINAL CONSTRUCTION

MOUNT THE WING TO THE FUSELAGE

The following steps will be easier to do if you

remove the ailerons and flaps.

❏

1. Measure the width of the fuselage at the leading

edge of the wing. It should be close to 3-1/8"

[79.4mm]. Mark the LE and TE of the wing on both

sides of the centerline exactly 1/2 this amount

(1-9/16" [39.7mm]). Do this on the top and bottom of

the wing.

Note: The photos in this section do not show the

flap servo.

❏

2. Trial fit the wing to the fuselage, centering it

between the marks you just made. The wing should be

slightly shorter than the opening in the fuselage. When

the flaps are hinged to the wing, the flap joiner rod will

be located on the TE of the wing. Slide the wing forward

in the opening and see if there is room for the flap joiner.

You may need to sand the leading edge of the wing flat,

as shown on the plan, to get the proper spacing.

-35-