Ready, Build, Build the tail surfaces – Top Flite TOPA0305 Part 1 User Manual

Page 11

GET

READY

TO

BUILD

1. Unroll the plan sheets, then roll them inside

out

so

they lie flat.

2.

Remove all the parts from the box. Use a

ballpoint pen (not a felt-tip pen) to lightly write the

name or size on each piece

so

you can identify it

later. Use the

die-cut patterns

on pages 8 & 9 to

identify and mark the die-cut parts before you

remove them from their die-cut sheets. Many of the

parts already have numbers stamped on them, but

in some cases the number is located alongside the

parts. You may remove all the die-cut parts from

their die sheets now or wait until you need them. If

a part is difficult to remove, don't force it out but cut

around it with a

#I1

blade. After you remove the

parts from their die sheets, lightly sand the edges

to remove slivers or die-cutting irregularities. Save

some of the larger scraps of wood.

DO NOT PUNCH OUT THE

ROUND LIGHTENING HOLE

W4, W5,

W6

Note: If you are going to install retracts, don't

punch out the round

lightening hole

in the die-cut

3/32"

balsa wing ribs W4, W5 and W6. Instead,

apply thin CA around the lightening hole to glue it

in place.

3.

Separate the parts into groups such as stab,

fin, wing and fuse.

Store smaller parts in zipper-top food storage

bags.

BUILD THE TAIL SURFACES

Make the skins

for the tail surfaces

1. See the Hot Tip that follows and use six

1/16"

x

3"

x 30" balsa sheets to make two

1/16" x 9"

x

30"

stab skin

planks.

If you're building

the straight-tail, make a third

plank

for the

finlrudder skin from three more 1/16"

x

3"

x

30"

balsa sheets.

Hey, if you're building the V-tail it

looks as if you are going to have three sheets

of

1/16"

balsa leftover!

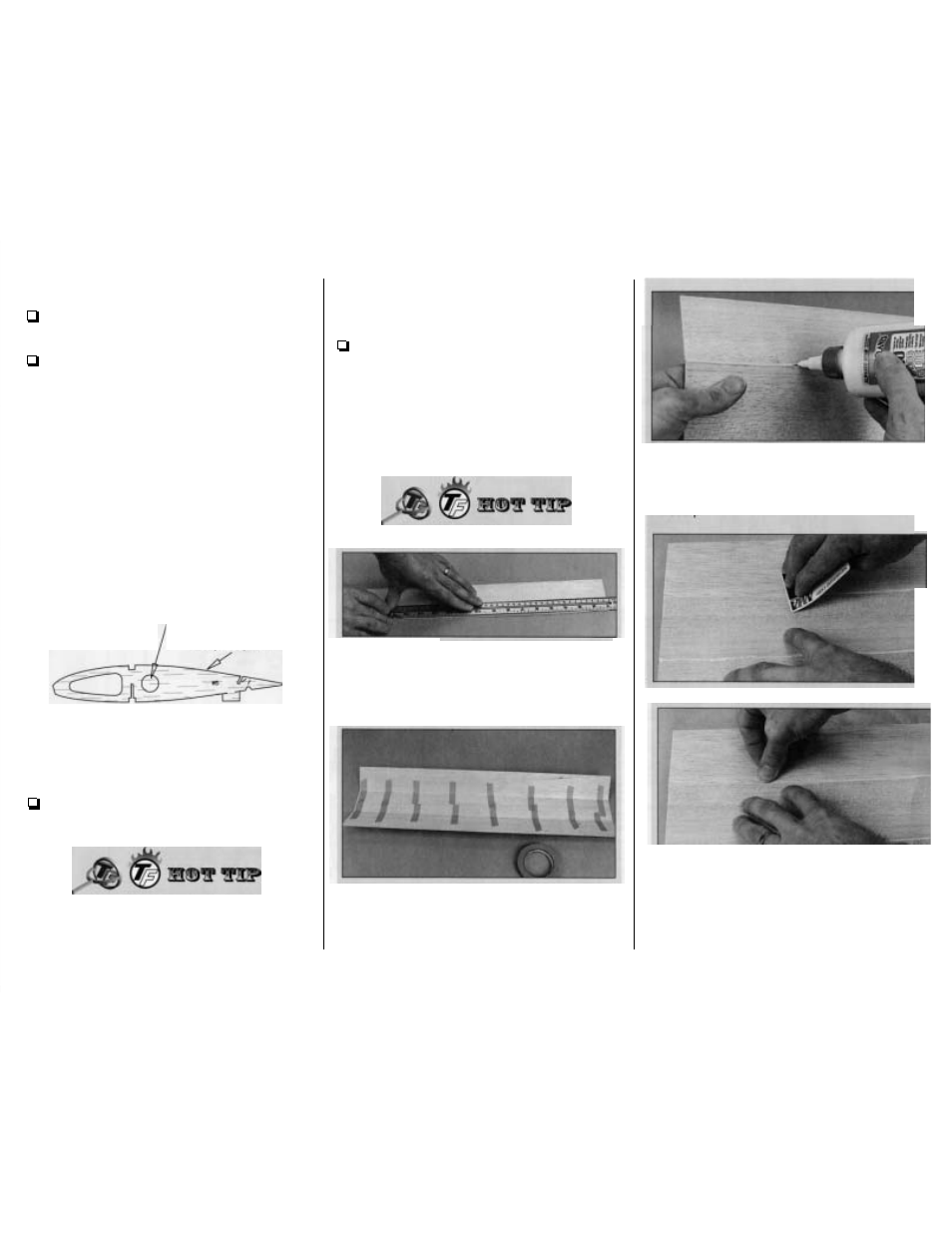

HOW TO MAKE THE SKINS

A. Use a straightedge and a sharp

# I 1

blade to

true the joining edges of the sheets. When you

trim them, do not cut all the way through the first

time but make

several passes so

you

slice

the

wood instead of splitting it.

B. Tightly tape the sheets together with masking

tape placed about every 4" along the seams. The

sheets will not lay flat because they are tightly

taped together.

C. Place wax paper on your workbench. Flip the

sheets over and apply a bead of aliphatic resin

(wood workers glue

such as Great Planes Pro"")

between the seams. Immediately proceed to the

next steD.

-10-

D. Use a credit card or thin peice of plywood to

squeegee the excess glue from the seam. Wipe

the glue off your squeegee with a paper towel or a

stick of wood. Immediately proceed to the

next step.