Top Flite TOPA0140 User Manual

Page 7

IMPORTANT BUILDING NOTES

•

There are two types of screws used in this kit.

Sheet metal screws are designated by a

number and a length.

For example #6 x 3/4" [19.1mm]

Machine screws are designated by a number,

threads per inch and a length.

For example 4-40 x 3/4" [19.1mm]

•

When you see the term

test fit in the

instructions, it means that you should first

position the part on the assembly without using

any glue, then slightly modify or

custom fit the

part as necessary for the best fit.

•

Whenever the term

glue is used you should rely

upon your experience to decide what type of

glue to use. When a specific type of adhesive

works best for that step we will tell you what type

of glue to use.

•

Whenever just

epoxy is specified you may use

either 30-minute epoxy or 6- minute epoxy.

When 30-minute epoxy is specified it is highly

recommended that you use only 30-minute (or

45-minute) epoxy because you will need the

working time and/or the additional strength.

•

Occasionally we refer to the

top or bottom of the

model or

up or down. To avoid confusion, the

top or bottom of the model is as it would be

when the airplane is right side up and will be

referred to as the top even if the model is upside

down during that step,

i.e. the top main spar is

always the top main spar even if the wing is

upside down when you are working on it.

Similarly,

move the former up means move the

former toward the top of the fuselage even if the

fuselage is upside down when you are working

on it.

•

When you get to each step, read that step

completely through to the end before you

begin. Frequently there is important information

or a note at the end of the step that you need to

know before you start.

•

Photos and sketches are placed ahead of the

step they refer to. Frequently you can study

photos in following steps to get another view of

the same parts.

COMMON ABBREVIATIONS

Deg = degrees

Elev = elevator

Fuse = fuselage

" = inches

LE = leading edge

Ply = plywood

Stab = stabilizer

TE = trailing edge

LG = landing gear

mm = millimeters

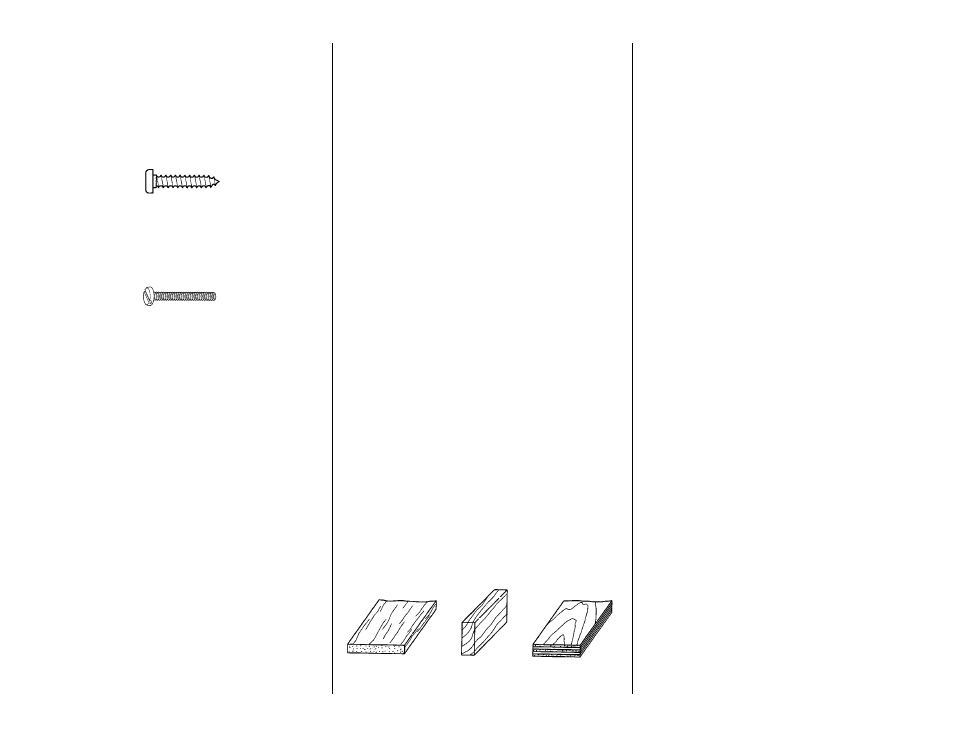

TYPES OF WOOD

BALSA BASSWOOD PLYWOOD

GET READY TO BUILD

1. Unroll the plan sheets. Roll them inside out so

they lie flat.

2. Remove all the parts from the box. Use a

ballpoint pen (not a felt tip pen) to lightly write the

name or size on each piece so you can identify it

later. Use the

die-cut patterns on pages 8 & 9 to

identify and mark the die-cut parts before you

remove them from their die sheets. Many of the

parts already have numbers stamped on them, but

in some cases the number is located alongside the

parts. You may remove all the die-cut parts from

their die sheets now or wait until you need them. If a

part is difficult to remove, don’t force it out but cut

around it with a #11 blade. After you remove the

parts from their die sheets, lightly sand the edges to

remove slivers or die-cutting irregularities. Save

some of the larger scraps of wood.

3. Separate the parts into groups such as stab,

fin, wing, and fuse. Zipper-top food storage bags

are handy to store parts in as you sort, identify and

separate them into subassemblies.

1/64" = .4mm

1/32" = .8mm

1/16" = 1.6mm

3/32" = 2.4mm

1/8" = 3.2mm

5/32" = 4mm

3/16" = 4.8mm

1/4" = 6.4mm

3/8" = 9.5mm

1/2" = 12.7mm

5/8" = 15.9mm

3/4" = 19mm

1" = 25.4mm

2" = 50.8mm

3" = 76.2mm

6" = 152.4mm

12" = 304.8mm

15" = 381mm

18" = 457.2mm

21" = 533.4mm

24" = 609.6mm

30" = 762mm

36" = 914.4mm

METRIC CONVERSION

1" = 25.4mm (conversion factor)

- 7 -