Top Flite TOPA0140 User Manual

Page 57

your wheels to the landing gear with a 3/16"

[4.8mm] wheel collar on both sides of both wheels.

Secure the wheel collars with a drop of thread lock

on the set screws.

Note: We recommend you file a small flat spot on

the landing gear wire where the set screws

are located.

Skip to step 5.

❏

2. Use a small file or a rotary tool with a cut-off

wheel to grind small flat spots on the main landing

gear wires so the set screws in the retracts will

securely lock the wires in position. Adjust the flat

spots until you can achieve the alignment detailed

earlier in the manual when you were first installing

the landing gear. File flat spots on the ends of the

wires for the set screws of the axles and on the

axles for the set screws of the wheel collars.

❏

3. Securely fasten the axles to the landing gear

wires. Use a drop of thread lock on the set screws

or, for the most security, silver solder the axles to

the main gear with the set screws in place.

❏

4. Securely mount the landing gear to the

retracts using a small drop of thread lock on the

set screws. Mount the wheels to the axles with

wheel collars and, you guessed it, a small drop of

thread lock (if you don’t thread lock the set screws,

you will lose a wheel!).

❏

5. Mount a 1-1/4" [32mm] tail wheel on the tail

gear wire and secure it with a 3/32" [2.4mm] wheel

collar and a drop of thread lock.

❏

6. If you haven’t already done so, route your air

lines and servo connectors in the wing and in the

fuse. Connect the servos in the fuselage to the

receiver and plug in servo extension cords for the

aileron and flap servo. Make sure no wires or air

lines interfere with any of the servo arms,

pushrods, etc.

❏

7. Take the servo arms off your servos, turn on

your transmitter and center all the trims. Reinstall all

the servo arms and secure them with the screws.

❏

8. Double-check all the servos and make sure

the servo arms are secure and all the clevises

have a silicone retainer.

❏

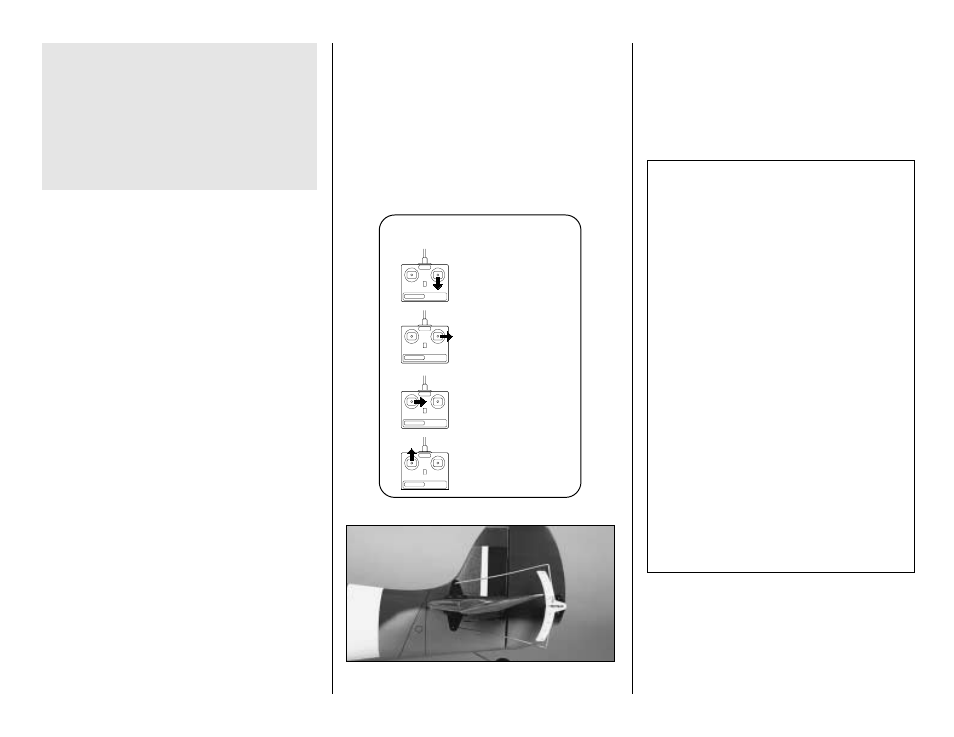

9. Make sure the control surfaces move in the

proper direction as illustrated in the following sketch.

❏

10. Adjust your pushrod hookups and set up

your radio to provide the control surface

movements as follows. Use a ruler or a Great

Planes AccuThrow

™

Control Surface Deflection

Meter (GPMR2405) to measure the throws.

TRIM MIXING: If your transmitter has Elevator to

Retract mixing, we recommend mixing 1/16"

[1.6mm] of down elevator when the gear is

retracted. This will keep the nose level when the

gear is cycled.

CONTROL SURFACE THROWS

Throws are measured at the widest part of the

control surface. We recommend the following

control surface throws:

High rate

Low rate

Elevator

5/8" up

1/2" up

5/8" down

1/2" down

Rudder

1-1/8" left

7/8" left

1-1/8" right

7/8" right

Ailerons

3/4" up

1/2" up

5/8" down

3/8" down

Flaps

Landing

position #1

1/2"

position #2

1-1/4"

The balance point and control surface

throws listed in this manual are the ones at

which the Spitfire flies best. Set up your

aircraft to those specifications. If, after a few

flights, you would like to adjust the throws

or C.G. to suit your tastes, that is fine. Too

much control surface throw can make your

model difficult to control or force it into a

stall, so remember...More is not better.

CARBURETOR WIDE OPEN

RUDDER MOVES RIGHT

LEFT AILERON MOVES DOWN

RIGHT AILERON MOVES UP

ELEVATOR MOVES UP

4-CHANNEL

TRANSMITTER

(STANDARD MODE 2)

4-CHANNEL RADIO SETUP

TRANSMITTER

4-CHANNEL

TRANSMITTER

4-CHANNEL

TRANSMITTER

4-CHANNEL

- 57 -