Slant fin corp, Installation and operation instructions chs series – Slant/Fin CHS-399 User Manual

Page 8

Slant Fin Corp.

│ Installation and Operation Instructions

CHS Series

8

3.0 BOILER LOCATION

In all cases, the CHS boiler must be installed indoors in a dry location where the ambient temperature must be

maintained above freezing and below 100

F [38

C]. All boiler components must be protected from dripping,

spraying water, or rain during operation and servicing. Consider the proximity of system piping, gas and

electrical supply, condensate disposal drain, and proximity to vent termination when determining the best boiler

location.

Water or flood damaged components must be replaced immediately with new factory-

approved components as failure to do so may result in fire, serious injury, or death.

Boiler Area Ventilation Air Openings

If boiler area clearances are less than the recommended clearances specified in Table 3-1, the boiler area must be

ventilated (Exception: if the boiler area/room has a volume of 150 ft

3

or greater, ventilation of the boiler room is

not required). Each ventilation air opening must meet the minimum requirements of 1 in

2

per 1000 Btu/hr, but

not less then 100 in

2

. The lower ventilation opening must be located within 6” of the floor while the upper

opening must be located 6” from the top of the space.

If the "Boiler Area" does not meet the recommended clearances listed in Table 3-1, and if

the boiler area has a volume less than 150 ft

3

, it is considered a Closet or Alcove. In US

/

Canada, PVC vent pipe and fittings shall not be used within the closet or alcove; only

approved CPVC, Polypropylene or Stainless Steel vent pipe and fittings can be used. See Table 4-4 for a list of

approved materials. Under all circumstances, the minimum clearances listed in Table 3-1 must be provided.

Closet Installations

For closet installations it is necessary to provide two ventilation air openings as shown in Figure 3-1, each

providing a minimum area equal to 1 in

2

per 1000 Btu/hr, but not less then 100 in

2

and within 6” of the top and

bottom of the closet door. See Table 3-1 for minimum clearances.

Alcove Installations

Alcove installations have the same minimum clearances as closet installations, except the front must be

completely open to the room at a distance no greater then 18” [457 mm] from the front of the boiler and the

room is at least three (3) times the size of the alcove. Provided these conditions are met, the boiler requires no

extra ventilation air openings to the space. See Table 3-1for minimum clearances.

Residential Garage Installations

When installed in a residential garage, mount the boiler a minimum of 18” [457 mm] above the floor. Locate or

protect the boiler so it cannot be damaged by a moving vehicle. Check with your local authorities for other

possible regulations pertaining to the installation of a boiler in a garage.

Wall Mounting Installations

The CHS is provided with integrated wall mounting brackets. Refer to Figure 3-2 for instructions and

illustrations on wall mounting.

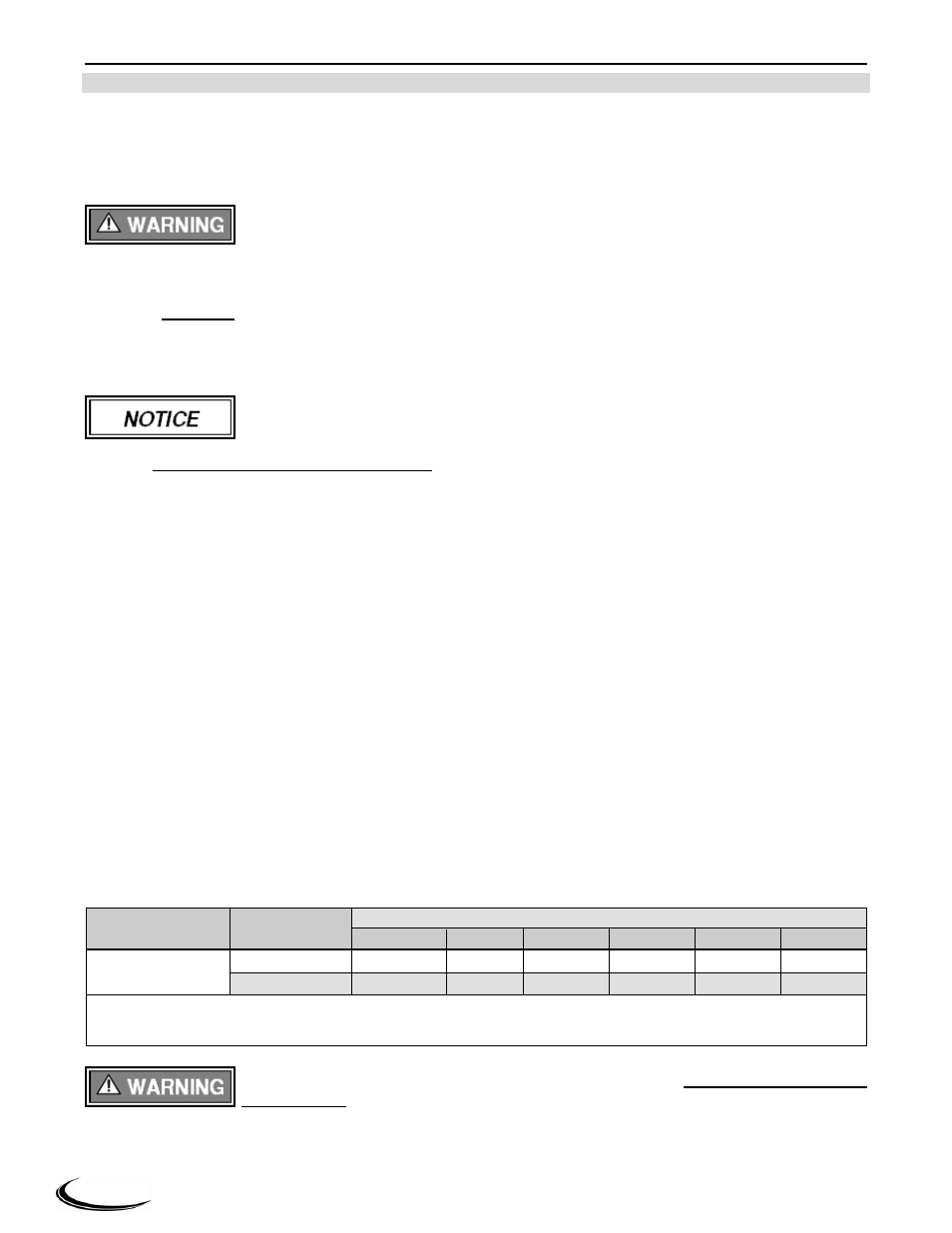

Table 3-1 Minimum Clearances for Installation and Service

Model No.

Clearances

Dimensions - inches [mm]

Front

Top

Sides

Back

Bottom

Flue Pipe

CHS 85-399

Minimum

24 [610]

1

12 [305]

4 [102]

0

9 [229]

1 [25]

Recommended

36 [914]

24 [610]

12 [305]

0

24 [610]

1 [25]

Notes:

1

6” if surface is removable allowing a minimum of 24” [610 mm] clearance (i.e. closet installation). See Ventilation Air

Opening dimensions in Figure 3-1.

Closet/alcove installations in US and Canada require approved CPVC, Polypropylene or

Stainless Steel vent and air-inlet pipe and fittings (see Table 4-4); PVC is not permitted.

Failure to follow these instructions may result in damage or serious injury.