Slant fin corp, Installation and operation instructions chs series – Slant/Fin CHS-399 User Manual

Page 16

Slant Fin Corp.

│ Installation and Operation Instructions

CHS Series

16

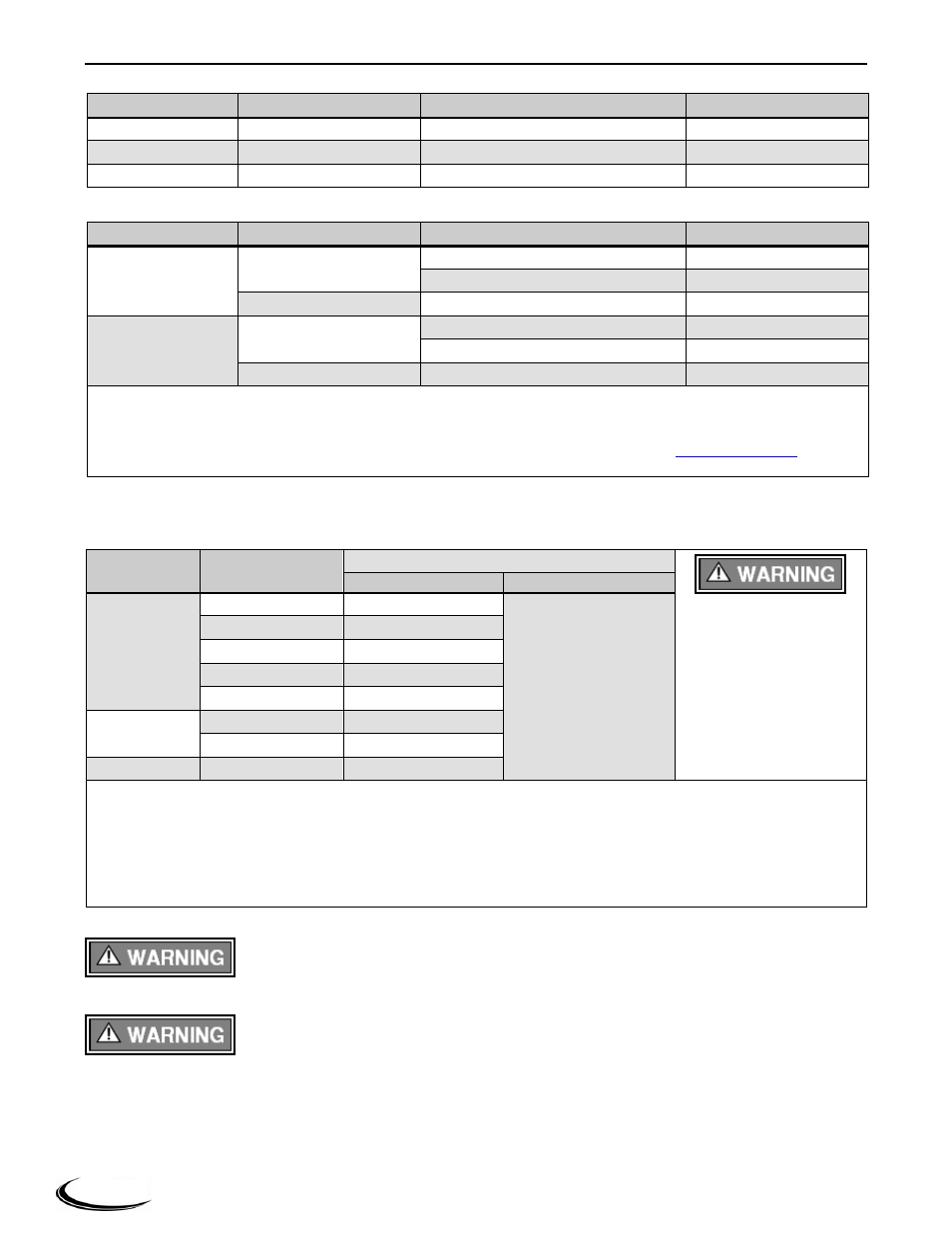

Table 4-2 CPVC Vent Pipe Transition Piece (used when venting with PVC)

Model No.

Vent Pipe Size

CPVC Transition Vent Pipe Length

Full Insertion Depth

CHS 85-110

3”

Minimum 5” [127 mm]

2-7/8” [73 mm]

CHS 155-250

3”

Minimum 5” [127 mm]

2-5/8” [67 mm]

CHS 300-399

4”

Minimum 5” [127 mm]

2-5/8” [67 mm]

Table 4-3 Appliance Adapters for Polypropylene and Stainless Steel Venting

Model No.

Vent Material

Venting Brand

Adapter Part No.

1,2

CHS 85-250

Polypropylene

DuraVent – PolyPro

300150

Centrotherm - InnoFlue

ISAA0303

Stainless Steel

DuraVent – FasNSeal

300715

CHS 300-399

Polypropylene

DuraVent – PolyPro

300151

Centrotherm - InnoFlue

ISAA0404

Stainless Steel

DuraVent – FasNSeal

303631

Notes:

1

Listed appliance adapters are only approved for use with the respective venting brand; i.e. a PolyPro appliance adapter

shall not be used with InnoFlue venting.

2

PolyPro and FasNSeal appliance adapters are available from DuraVent (1-800-835-4429 or

;

InnoFlue appliance adapters are available from Centrotherm Eco Systems (1-877-434-3432 or www.centrotherm.us.com).

Vent/Air-inlet Pipe Material

Table 4-4 Acceptable Vent and Air-Inlet Pipe Material

Items

1

Materials

2, 3

Venting System Standards

All Vent and Air-Inlet

materials installed on gas

fired appliances in CAN/US

must meet the Standards

listed in this Table. Failure

to comply could result in

fire, serious injury or death.

United States

Canada

4

Vent Piping

and Fittings

PVC - DWV

ANSI/ASTM D2265

All venting material in

Canada must be

ULC S636 approved.

See Note 4 below for

appropriate temperature

applications.

PVC Schedule 40

ANSI/ASTM D1785

CPVC Schedule 40

ANSI/ASTM F441

Stainless Steel (SS)

UL-1738

Polypropylene (PP)

-

Pipe Cement

PVC

ANSI/ASTM D2564

CPVC

ANSI/ASTM F493

Primers

PVC / CPVC

ANSI/ASTM F656

Notes:

1

Refer to Table 4-5 for Allowable Vent and Air-Inlet Pipe Sizes and Lengths.

2

PVC venting (exhaust and air-inlet) is not permitted within the Closet/alcove of a Closet/alcove installation.

3

The Air-inlet does not require high temperature pipe material. Check applicable local codes for acceptable materials.

4

ULC S636 PVC is approved for flue gas temperatures up to 149

o

F (65

o

C) and must only be used for low temperature

applications. High temperature applications requiring boiler supply water temperatures greater than 140

o

F (60

o

C) must

use ULC S636 CPVC, PP or SS.

The use of cellular core PVC (ASTM F891), cellular core CPVC, or Radel®

(polyphenolsulfone) in the exhaust venting system is prohibited. Failure to follow these

instructions may result in property damage, personal injury or death.

Covering non-metallic vent pipe and fittings with thermal insulation is prohibited. Failure

to follow these instructions may result in property damage, personal injury or death.