Slant fin corp – Slant/Fin CHS-399 User Manual

Page 66

Slant Fin Corp.

│ Installation and Operation Instructions

CHS Series

66

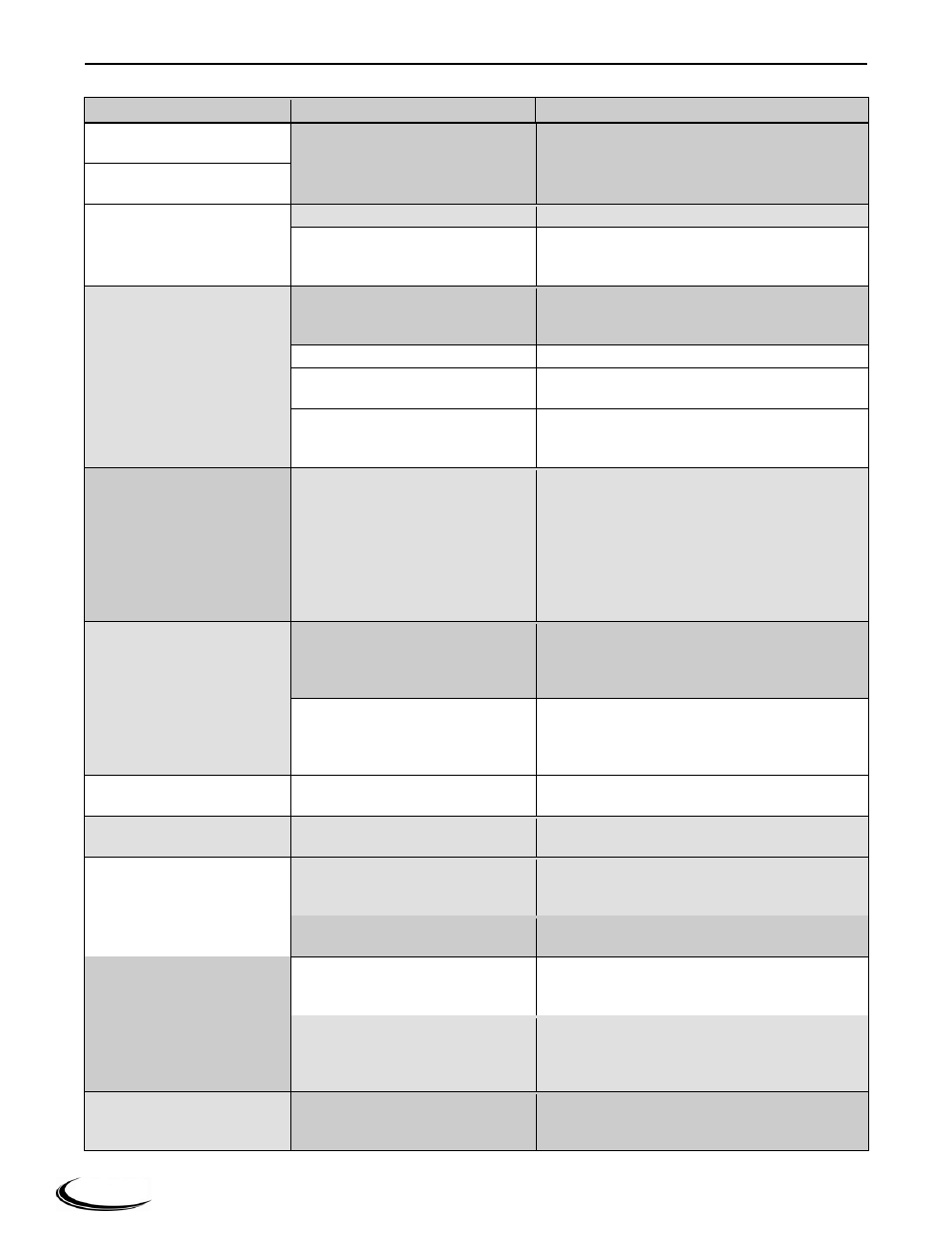

Table 15-1 Troubleshooting Chart

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

Hold 65 – Interrupted Air

Switch OFF

Hold 66 – Interrupted air

switch ON

Hold 67 – ILK OFF

Low Water Condition

Check operation of internal LWCO.

External Limit Tripped

Indication that an external limit (wired to “LIM”)

is open. Not a problem with boiler, check

external limit.

Lockout or Hold 79 – Outlet

High Limit

CH or DHW settings

Check if CH and/or DHW setpoint temperature

plus off hysteresis exceed “High limit” setpoint –

factory setting = 200°F (93°C).

CH or DHW pump problem

See

"

Inoperative CH or DHW pump

"

below.

Incorrect “Outlet high limit” setting

Increase “Outlet high limit” setting; maximum

setting = 200°F (93°C).

Incorrect “Outlet high limit

response” setting

Unless deemed unacceptable by local installation

codes, the “Outlet high limit response” should be

set to “recycle and hold” to prevent lockout.

Lockout or Hold 81 – Delta T

limit

OR

Appliance making banging or

hissing sounds

Insufficient water flow

Check Fuse

"B"

Check appliance pump.

Ensure plumbing is correct. Refer to Section

10.0 System Piping. Check that water pressure

is at least 15PSI.

Boiler heat transfer surfaces may be fouled

with scale or magnetite. Clean with Fernox

DS-40 Descaler and Cleanser. See Table 10-1.

Lockout 82 – Stack limit

Dirty heat exchanger

Inspect and if required clean the combustion

chamber and/or heat exchanger. Refer to Section

14.0 Annual Maintenance and Inspection and

Section 10.0 Boiler and Heating System Piping.

Incorrect “Stack limit setpoint”

Unless installed in Canada with PVC exhaust

venting, set “Stack limit setpoint” to maximum

setting of 220ºF (104ºC). In Canada PVC exhaust

venting is limited to 149ºF (65ºC).

Lockout 85 – Inlet/Outlet

Inversion Limit

Pump flowing in the wrong

direction

Ensure water circulation through the boiler is in

the correct direction, see Figure 10-1.

Lockout or Hold 88 – Outlet

T Rise limit

Insufficient water flow

See Lockout 81.

Hold 91– Inlet sensor fault

Sensor disconnected

Check sensor connection located on the bottom of

the heat exchanger. Check connection on control

board.

Faulty sensor

Check resistance of sensor and compare to

thermistor resistance chart, see Table 15-2.

Hold 92 – Outlet sensor fault

Sensor disconnected

Check sensor connection located on the top of the

heat exchanger. Check connection on control

board.

Faulty sensor

Check resistance of sensor and compare to

thermistor resistance chart, see Table 15-2. (Note

the Outlet sensor incorporates two sensors, check

resistance individually.)

Hold 95 – Stack sensor fault

Sensor disconnected

Check sensor connection located at the bottom of

the flue pipe inside the boiler cabinet. Check

connection on control board.