Ag 2, Rating plate 2, Duct furnace rating plate – Reznor HRPD Parts Manuals User Manual

Page 2

Form P-RG/RP/RBL, P/N 263984R4, Page 2

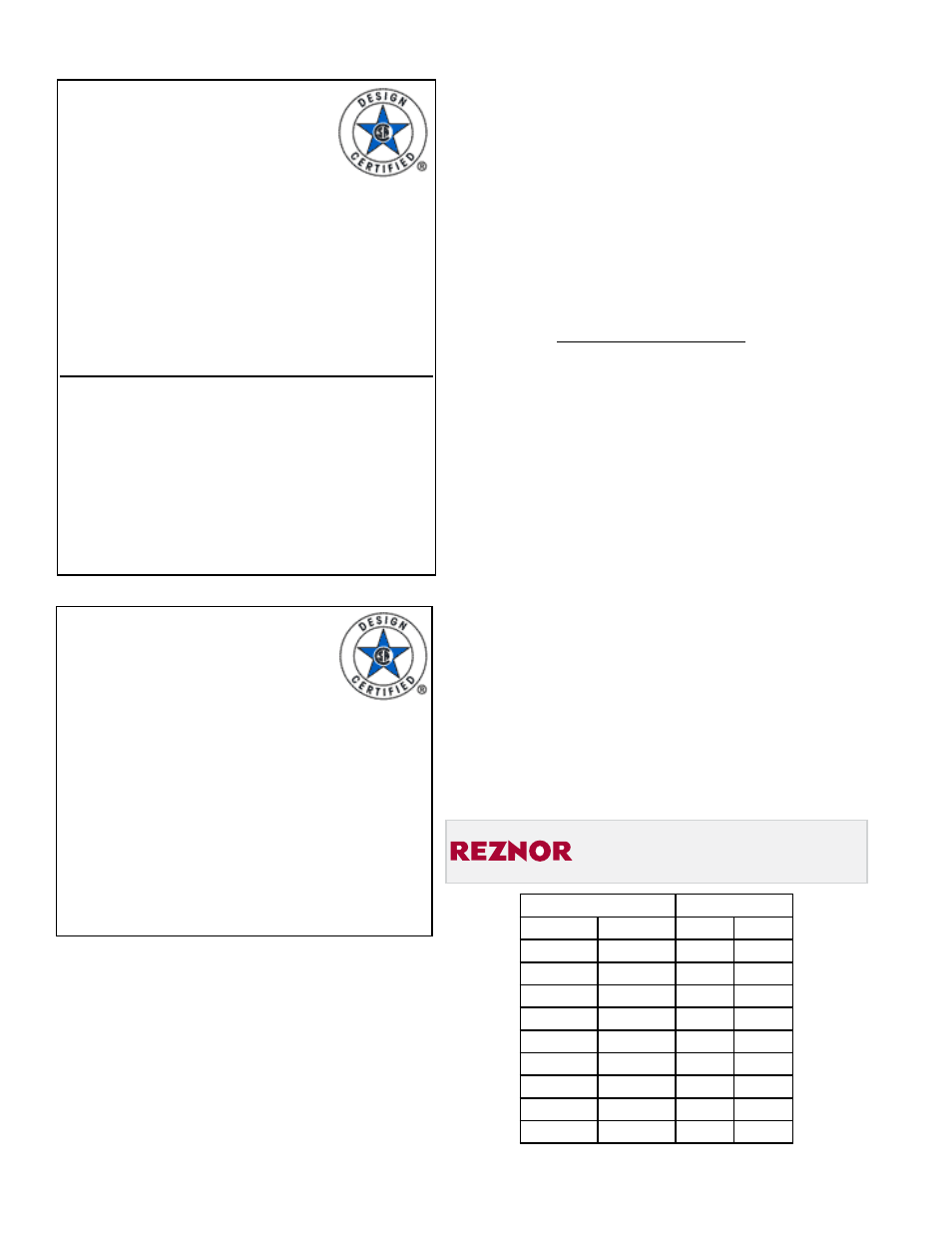

Blower Cabinet Rating Plate on Certified Packaged Units (see table on page 3)

Key to Cabinet Rating Plate

A = Standard

B = Model

C = Date of Manufacture

D = Motor Horsepower

E = Volts/Phase/Hertz/Amps

F = SCFM

G = Static Pressure (w.c.)

H = Drive AM Option Code

I = Wiring Diagram No.

Duct Furnace Rating Plate

De-Coding a Serial No.

Sample:

S BKI 95 W8 N 12345 MV3

1 | 2 | 3 | 4 | 5 | 6 | 7

1 = Stainless steel heat exchanger (with an aluminized heat

exchanger, there is no letter suffix

2 = Date code (see page 3)

3 = Pilot code (Reference Form P-VALVES)

4 = Valve code (Reference Form P-VALVES)

5 = N is natural gas; L is propane gas

6 = Consecutive number

7 = Maxitrol system (optional)

Key to Duct Furnace Rating Plate

A = Standard

B = Model and Size

C = Date of Manufacturer

D = Serial No.

E = Volts/PH/Hz/Amps

F & G = Natural Gas or Propane

H & I = Altitude

J = Orifice Drill Size

K = Normal Input (altitude adjusted)

L = Thermal Output (altitude

adjusted)

M = Minimum Input (altitude

adjusted)

N = Normal Manifold Pressure

O = Minimum Gas Supply

Pressure

P = Maximum Air Throughput

Q = Minimum Air Throughput

R = Normal Input (sea

level)

S = Thermal Output (sea level)

T = Minimum Input (sea

level)

Replacement Parts Tag - Each unit has a replacement

parts tag that includes the Model No. and the Serial No.

as well as a list of original common replacement parts.

Always provide the full model and serial numbers when

ordering replacement parts.

Identification Plate on Blower Cabinets Manufactured

Prior to Package Certification (see dates on page 3)

HP

Codes

®

MODEL NUMBER

SERIAL NUMBER

DRIVE NO.

WIRING DIAGRAM NO.

CFM _____ AT____ IN. W.C. MAX. E.S.P. AND ____ HP

VOLTS PHASE HERTZ AMPERES

Single-Speed Motors

2-Speed Motors

Code

HP

Code

HP

05

1

20

1/.44

06

1-1/2

21

1.5/.68

07

2

22

2/.88

08

3

23

3/1.3

09

5

24

5/2.2

11

7-1/2

25

7.5/3.3

12

15

26

10/4.4

13

10

14

20

REZNOR

MERCER, PA. USA 16137

Made

in

Mexico

DUCT FURNACE

CATEGORY I

FOR INDUSTRIAL/COMMERCIAL USE ONLY

ANSI Z83.8 [ AA ] - [ A ] CGA 2.6 [ AA' ] -M [ A' ] DUCT FURNACE

MODEL [ B ] [ C ]

SERIAL NO. [ D ]

[ E ] VOLTS [ E ] PH [ E ] HZ MAXIMUM TOTAL INPUT [ E ] AMPS

TYPE OF GAS: [ F ]

[ G ]

ORIFICE SIZE [ J ] DRILL HAS BEEN FACTORY ADJUSTED

FOR USE AT [ H ] FEET [ I ] METERS OF ALTITUDE.

SEA

LEVEL

ALT.

ADJUSTED

NORMAL INPUT

[ R ] [ K ]BTU/HR.

OUTPUT CAPACITY

[ S ] [ L ]BTU/HR.

MINIMUM INPUT(2,M,MB,MV MODELS)

[ T ] [ M ]BTU/HR.

NORMAL MANIFOLD PRESSURE

[ N ] IN.W.C.

MIN. PERMISSIBLE GAS SUPPLY PRESSURE

FOR PURPOSE OF INPUT ADJUSTMENT.

[ O ] IN.W.C.

MAXIMUM THROUGHPUT [ P ] C.F.M.

MINIMUM THROUGHPUT [ Q ] C.F.M.

CLEARANCES TO COMBUSTIBLE CONSTRUCTION: VENT CAP-10' , BOTTOM- 3",

FLUE CONNECTION-6", SERVICE SIDE- WIDTH OF UNIT, OPPOSITE SIDE-6"

THIS UNIT SHALL BE INSTALLED ON THE POSITIVE PRESSURE SIDE OF THE

AIR CIRCULATING BLOWER.

THIS UNIT MAY BE INSTALLED DOWNSTREAM FROM A REFRIGERATION

SYSTEM (USE DRAIN OPTION CS1).

THIS UNIT MAY BE USED WITH DUCTS.

THIS UNIT IS FOR OUTDOOR INSTALLATION ONLY.

MINIMUM OPERATIONAL AMBIENT AIR TEMPERATURE: -40 DEG. F

THIS UNIT IS FOR USE WITH NATURAL GAS AND PROPANE. A CONVERSION

KIT AS SUPPLIED BY THE MANUFACTURER, SHALL BE USED TO CONVERT

THIS DUCT FURNACE TO THE ALTERNATE FUEL.

FOR ALTERNATE INSTALLATIONS USE THE LATEST EDITIONS OF THE

APPROPRIATE STANDARD LISTED BELOW:

FOR AIRCRAFT HANGERS USE STANDARD ANSI/NFPA 409

FOR PARKING STRUCTURES USE STANDARD ANSI/NFPA 88A

FOR REPAIR GARAGES USE STANDARD ANSI/NFPA 88B

REZNOR

MERCER, PA., U.S.A. 16137

PACKAGED DUCT FURNACE

FOR INDUSTRIAL/COMMERCIAL USE ONLY

DESIGN CERTIFIED FOR A.G.A REQUIREMENTS UNDER

[ A ] PACKAGED DUCT FURNACE STANDARD

MODEL [ B ]

[ C ]

SERIAL NO.

[ D ]

HP

[ E ] VOLTS [ E ] PH [ E ] HZ MAXIMUM TOTAL INPUT [ E ] AMPS

IF EQUIPPED WITH R.E.C. OPTION, ADD [ V ] AMPS

EQUIPPED FOR OPERATION AT AN AIR FLOW OF [ F ] SCFM

AGAINST A STATIC PRESSURE OF [ G ] INCHES WATER COLUMN.

DRIVE NO. [ H ]

WIRING DIAGRAM [ I ]

SEE MANUFACTURER'S INSTRUCTIONS FOR OTHER AIR FLOW

CAPACITIES.

FILTERS, WHEN USED, MUST BE INSTALLED EXTERNAL TO THE

HEATING CASING.

REFER TO THE RATING PLATE OF THE DUCT FURNACE FOR

ADDITIONAL INFORMATION.