Filters, Manifold gas pressure, 1b. blower belts – Reznor DV Operation Manual (for units built before August 2003) User Manual

Page 4: Recommended bearing lubrication schedule in months, Quantity and size of filters by model, Re s, Figure 1 - belt tension, Figure 2 - gas pressure tap locations

Form

O-DV/RDF/ADF, P/N 148385, Page 3

R

E

S

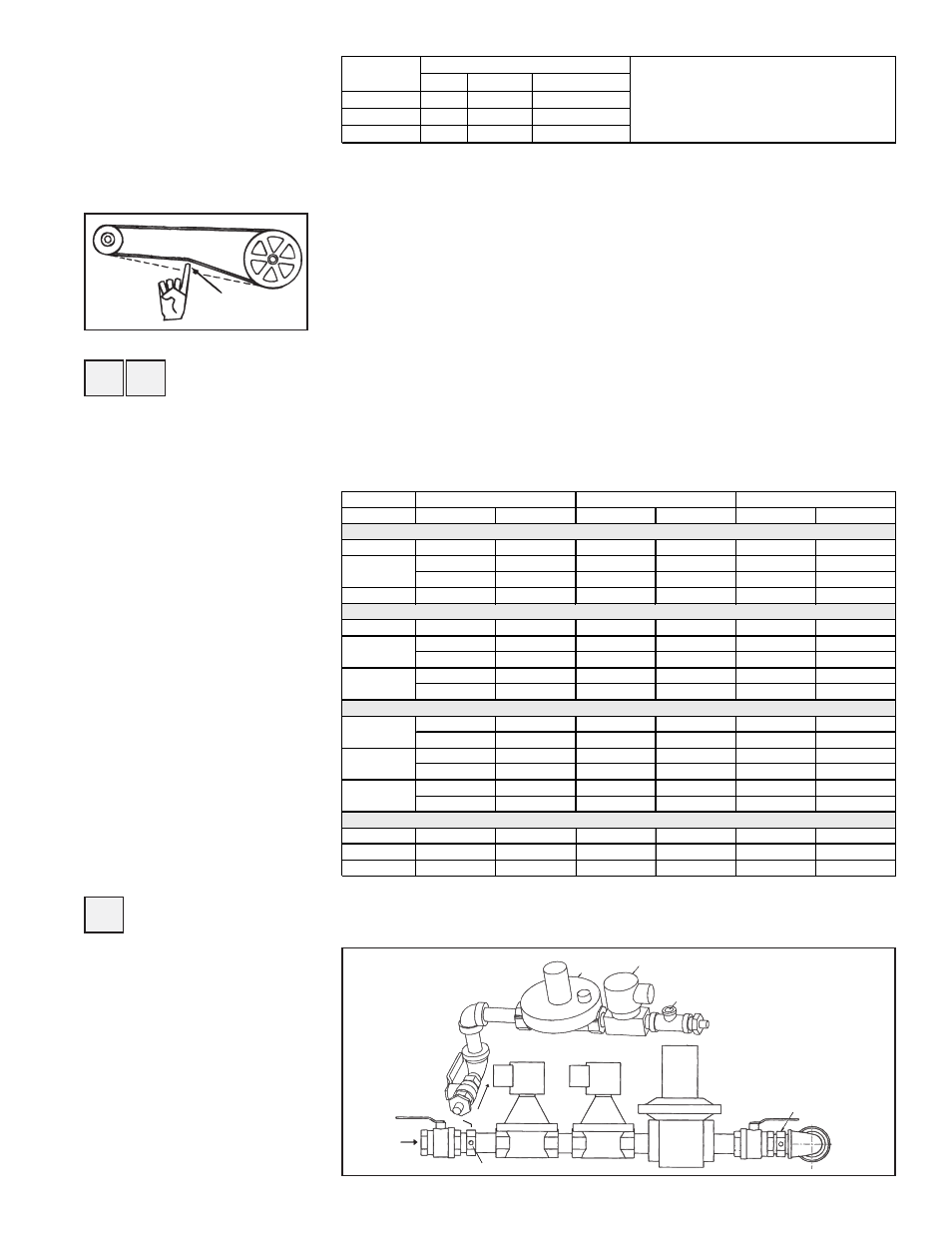

1B. Blower Belts

Check belts for proper tension and wear. Adjust belt tension as needed. Re-

place worn belts.

Proper belt tension is important to the long life of the belt and motor. A loose

belt will cause wear and slippage. Too much tension will cause excessive

motor and blower bearing wear. If adjustment is required, adjust belt tension

by means of the adjusting screw on the motor base until the belt can be de-

pressed 1/2" to 3/4" (FIGURE 1). Tighten the lock nut on the adjusting screw.

Be sure the belt is aligned in the pulleys.

FIGURE 1 - Belt Tension

2. Filters

If the system includes filters, check the filters quarterly. Filters could be either

in an optional filter cabinet (DV/RDF/ADF) or in the optional inlet base (DV).

To access filters in a filter cabinet, remove the filter cabinet door panels. Clean

or replace as needed. If removed, be sure to put blockoff plates in filter rack.

If the filters are in the perimeter of the inlet base of a Model DV; they are two-

inch permanent filters. Remove and clean the filters as needed.

3/4 (19mm)

3. Manifold Gas

Pressure

Semiannually, check the gas pressure to the burner and to the pilot. Measure

both manifold pressure and pilot supply pressure with the blower in opera-

tion. Verify against pressures listed on the rating plate.

Recommended Bearing

Lubrication Schedule in

Months

Bearing Bore Diameter (Inches)

RPM

1/2 to 1 >1 to 1-1/2 >1-1/2 to 1-15/16

to 1000

6

6

6

1001 - 1500

5

5

5

1501 - 2000

5

4

5

NOTE: If unusual environmental conditions

exist (temperatures below 32°F or above

200°F; moisture; or contaminants) more

frequent lubrication is required.

Quantity and Size of

Filters by Model

Type

Thickness

1"

2"

1"

2"

1"

2"

Model RDF with Optional Filter Cabinet

1

-

-

(3)12x35

(4)12x35

-

-

-

-

(4)12x35

(4)12x35

-

-

-

-

(4)12x24

(4)12x24

-

-

3

-

-

(12)12x35

(10)12x35

-

-

Model ADF/ADFH with Optional Filter Cabinet

300

(5)12x30-5/8 (5)12x30-5/8

(10)10x16

(10)10x16

(5)12x32

(5)12x32

(5)12x20

(5)12x20

(5)12x20

(5)12x20

(5)12x20

(5)12x20

(5)12x25

(5)12x25

(5)12x25

(5)12x25

(5)12x26

(5)12x26

(5)12x25

(5)12x25

(5)12x25

(5)12x25

(5)12x25

(5)12x25

(5)12x30-5/8 (5)12x30-5/8

(5)12x32

(5)12x32

(5)12x32

(5)12x32

Model DV with Optional Filter Section

-

(4)16x16

(4)16x16

(4)16x16

(4)16x16

(4)16x16

-

(4)16x20

(4)16x20

(4)16x20

(4)16x20

(4)16x20

-

(6)16x20

(6)16x20

(6)16x20

(6)16x20

(6)16x20

-

(6)16x25

(6)16x25

(6)16x25

(6)16x25

(6)16x25

-

(16)16x16

(16)16x16

(16)16x16

(16)16x16

(16)16x16

-

(6)16x25

(6)16x25

(6)16x25

(6)16x25

(6)16x25

Model DV with Inlet Base with Filters

109, 112

-

-

-

(8) 10x12

-

-

115, 118

-

-

-

(8)15x20

-

-

122, 125

-

-

-

(16)20x20

-

-

109, 112

115, 118

122, 125

500

Disposable

Permanent

Pleated Disposable

700, 1200

2

FIGURE 2 - Gas Pressure

Tap Locations

Inlet Pressure Tap

Valve

Valve

Regulator

Manifold Pressure Tap

Gas

Supply

Pilot

Regulator

Pilot Solenoid Valve

Pilot Pressure Tap