Reznor DV Operation Manual (for units built before August 2003) User Manual

Page 24

Form

O-DV/RDF/ADF, P/N 148385, Page 23

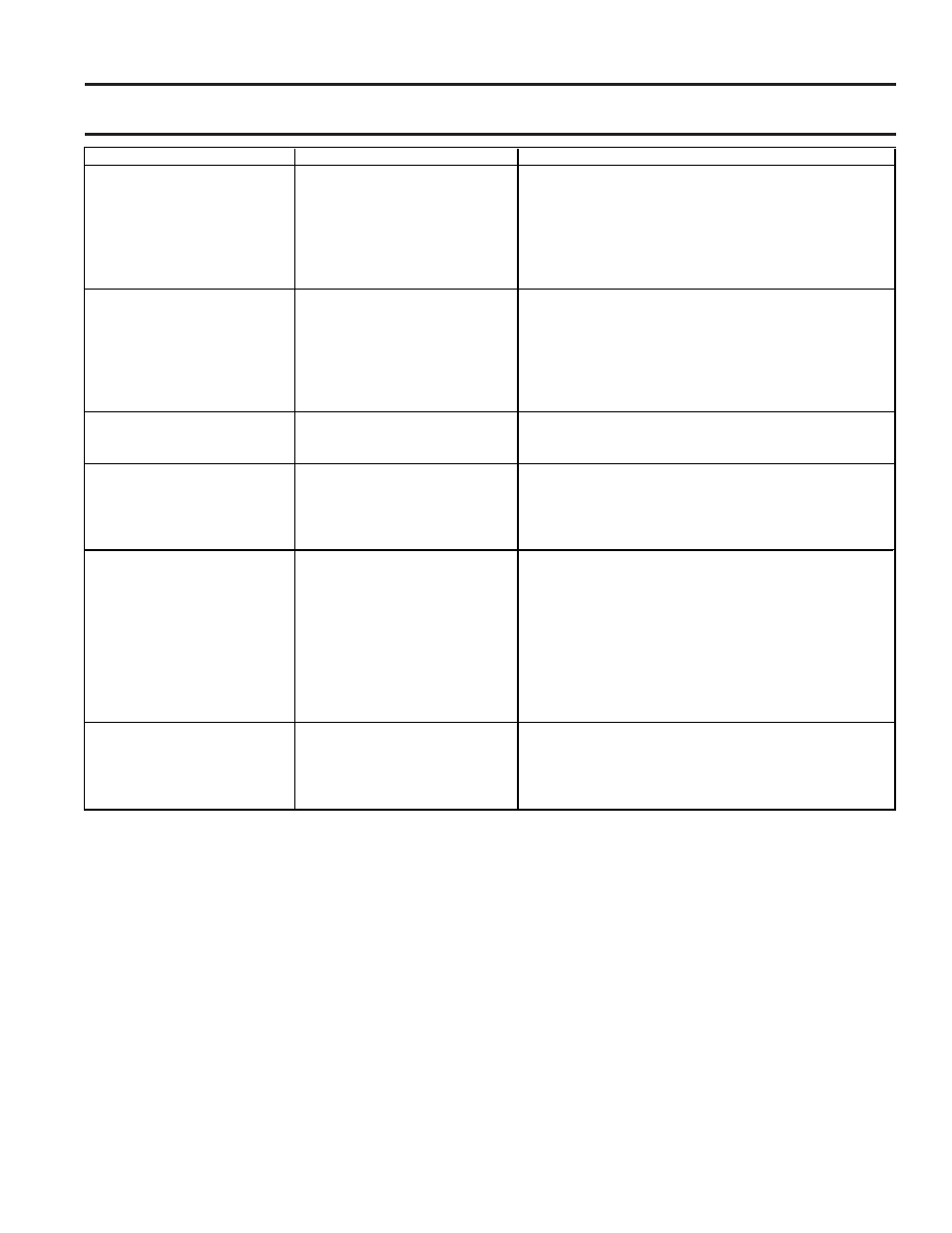

Chart 2 - Troubleshooting Optional Evaporative Cooling Module (Models ADF/ADFH)

WARNING: Disconnect the power before servicing the cooling module. Failure to do so can

cause electrical shock, personal injury or death.

Problem

Probable Cause

Remedy

Float & Pump Control System - Pump

does not run. Unit is calling for cooling

(i.e. console control switch is in cooling

position) and reservoir is full.

1. Electrical connections

1. Verify all electrical connections. See Wiring Diagram.

2. Electric float switch on pump

2. Check position of the actuators on the electric float switch.

3. Dirty pump

3. Clean pump.

4. Defective pump

4. Replace pump.

Float & Pump Control System -

Required water level (3") not

maintained

1. Float valve

1. Adjust float valve. See Filling and Adjusting Water Level.

2. Optional drain and fill valves

2. Check valve for proper operation.

3. Incorrect overflow pipe nipple -

should be 3-1/2"

3. Replace pipe nipple.

4. Drain leaking

4. Tighten drain plug.

Water running off of media pads

1. Excessive water flow

1. Adjust ball valve in distribution line. See Maintenance Section,

Paragraph 7.

2. Media pads need cleaned or replaced.

2. Clean or replace media pads. See Maintenance Section, Paragraph 7.

Water not distributing evenly

1. Distribution line clogged

1. Flush distribution line. See Maintenance Section, Paragraph 7.

2. Holes in distribution line turned

2. Check position of distribution line. Holes should be spraying upward.

If not positioned with holes toward top, adjust position of PVC line.

3. Incorrect voltage to pump (Float &

Pump control system)

3. Check voltage at pump terminal in cooling module junction box.

Media pads becoming clogged and

discolored quickly (scale/salt deposits)

and/or rapid deterioration of the float

switch (Float and Pump Control

System)

1. Bleed off line clogged

1. Clean bleed line.

2. Excessive water flow

2. Reduce flow by adjusting ball valve in distribution line. See

Maintenance Section, Paragraph 7.

3. Inadequate bleed off

3. A uniform build-up of minerals on the entering air face of the media

indicates insufficient bleed off. Increase the rate until the mineral deposits

dissipate.

Water blowoff from media

1. Media pads installed incorrectly

1. Install media pads correctly. See Maintenance Section , Paragraph 7.

pads or water being pulled from

reservoir

2. Requires moisture elimination pad (over

600 FPM)

2. Install moisture elimination pad. Consult factory.

3. Water level not 3 inches (float & pump

control system)

3. See second problem listed above (Required water level not being

maintained.)