Gas train (cont'd) manifold arrangements – Reznor DV Operation Manual (for units built before August 2003) User Manual

Page 17

Form

O-DV/RDF/ADF, P/N 148385, Page 16

If the gas train includes either or both high and low gas pressure switches, the

switches monitor gas pressure downstream from the safety valves.

If the gas pressure in a system equipped with a high gas pressure switch (stan-

dard with manifold Options BM 78, 79, 80 and 81; Option BP2 with other

manifolds) exceeds the setpoint, the switch will open the electrical circuit to

the burner, stopping all gas flow. The high gas pressure switch is a manually

reset device.

A low gas pressure switch (Option BP3) will shutoff the gas flow if the gas

pressure drops below the setpoint of the low pressure switch. The low gas

12. Gas Train (cont'd)

Manifold

Arrangements

Description: The manifold is the gas train from the gas supply connection to

the burner. The manifold selection ordered determines the manifold arrange-

ment including all of the gas train components except the main control valve.

Manifold arrangements are available for varying BTUH ranges and gas con-

trols and meet ANSI, CSA, FM or GAP (former IRI) requirements.

All manifold arrangements include two 5psi rated manual shutoffs.

These systems are designed to operate on a natural gas supply differential

pressure range of a minimum of 4.3-5.0" w.c. plus the manifold pressure drop.

Maximum supply pressure depends on manifold selection; see below. If the

gas supply pressure is above the maximum allowed, it is necessary to install a

field-supplied step-down gas regulator in the supply line. Order and install the

appropriate Gas Regulator Kit, Option CZ1 (1") or CZ2 (1-1/2"). Follow the

instructions provided with the kit. Measure the gas pressure between the step-

down regulator and the unit.

Maximum Supply Pressure by Manifold

(Refer to the wiring diagram or rating plate to identify the manifold on the

system being serviced.)

Manifold Option BM75, BM76, BM77 - 1/2 psi

Manifold Option BM78, BM79 - 2 psi

Manifold Option BM80, BM81 - 5 psi

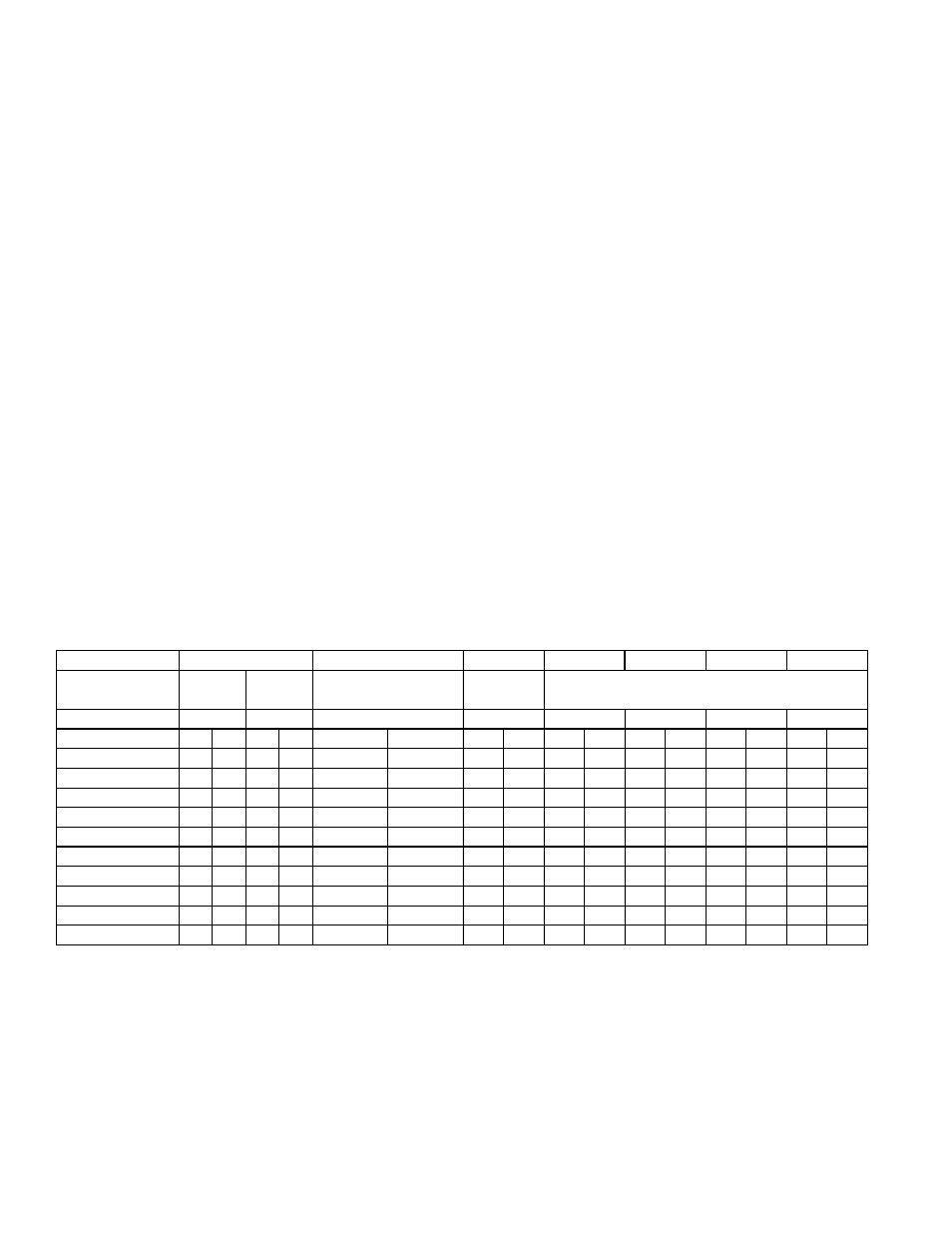

The table below lists the minimum supply pressure required for manifold and

gas control combinations. Refer to the wiring diagram to be sure which combi-

nation of options applies to the system being serviced. (NOTE: Not all options

are applicable on all models.)

OPERATION/SERVICE SECTION (cont'd)

Minimum Supply Gas Pressure ("w.c.) for Full Fire

Manifold Option

with Gas Control

Option

Manifold Size

MBH

Nat Pro Nat Pro

Nat

Pro

Nat

Pro

Nat

Pro

Nat

Pro

Nat

Pro

Nat

Pro

250

4.0

1.4

4.0 N/A

4.1

1.6

4.3

1.5

4.4

1.6

4.6

1.6

4.5

1.6

5.1

1.8

500

5.3

1.9

5.0 N/A

5.8

2.3

6.2

2.2

6.0

2.3

5.2

1.9

5.0

1.7

5.3

1.9

750

7.5

2.7

6.8 N/A

8.5

3.3

9.5

3.3

8.4

3.3

6.1

2.3

5.7

2.0

5.5

1.9

1000

12.4

4.7

11.7

4.6

7.4

2.8

6.7

2.4

5.8

2.1

1250

9.1

3.5

8.0

2.9

6.2

2.2

1500

11.2

4.3

9.6

3.5

6.6

2.4

1750

13.6

5.3

11.5

4.2

7.2

2.6

2000

16.5

6.3

13.7

5.0

7.8

2.8

2500

23.3

8.9

18.9

7.0

9.4

3.4

3000

11.3

4.1

AG1

BM75

1"

1-1/4"

AG3

AG 30, 31, 32, 33, 35,

36, 37, 47, 48, or 51

BM76

BM78

AG 49, 50

BM77

1-1/4"

2"

1"

1"

1"

1"

BM80

BM81

BM79

AG 30, 31, 32, 33, 35, 36, 37, 47, 48, or 51