0 maintenance (cont'd), 0 operation and service, 3 maintenance procedures (cont'd) – Reznor ADFH Operation Manual User Manual

Page 8: 1 control locations, 2 electronic circuit board with lights

Form O-ADF/RDF, P/N 148385R2, Page 8

2.0 Maintenance

(cont'd)

2.3 Maintenance

Procedures

(cont'd)

2.3.7 Optional Evaporative Cooling Module (cont'd)

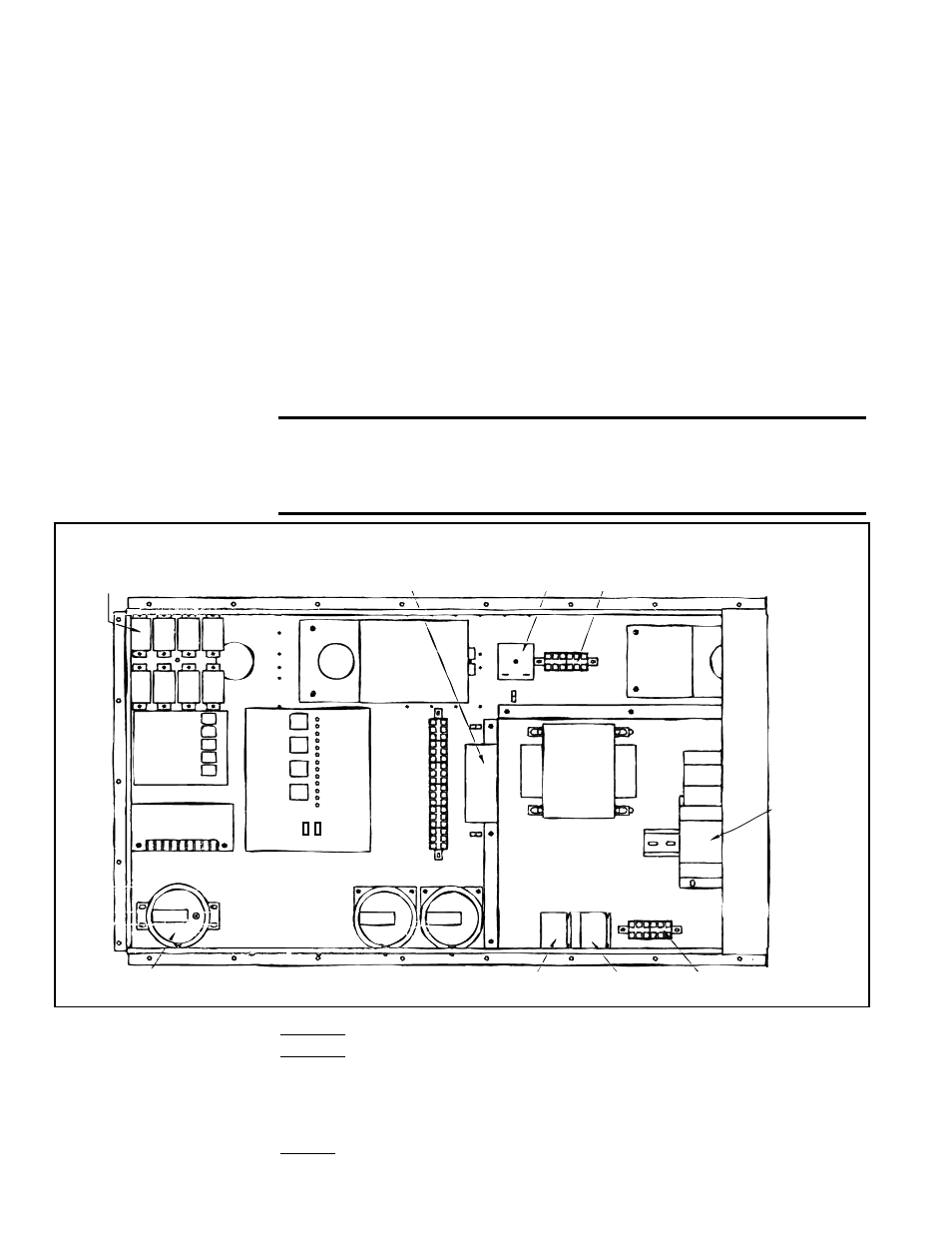

FIGURE 9 - Control Identification and Typical Locations

Control

Relays

Outside Air Cutoff

(high ambient limit control)

Time Delay

Relay

24-volt Terminals

Ignition

Module

Maxitrol Amplifier

or Signal

Conditioner

Service

Switches

St

atus Light

s

Circuit

Board

24-V

olt T

erminals

Bypass

Damper

Motor

Return

Air

Damper

Motor

Motor

Starter

Transformer

Line Voltage

Terminals

Starter

Relay

Relay for

Optional 2-Speed

High

Low

Standard

Pressure

Switches

Optional Dirty Filter

Pressure Switch

3.0 Operation and

Service

3.1 Control Locations

To service this system, it is necessary to understand the normal operation of the con-

trols and the function of the diagnostic circuit board. Refer to the electrical box drawing

in

FIGURE 9 and to the individual illustrations to identify and locate each of the con-

trols. The wiring diagrams for this unit are located in the main electrical box.

WARNING: Service work on this system should only be done

by a qualified gas service person. The service information and

the troubleshooting guides are intended as an aid to a qualified

service person.

3.2 Electronic

Circuit Board

with Lights

Location: Control Compartment Electrical Box (See FIGURE 9)

Function: The diagnostic lights on the circuit board are designed to assist in trouble-

shooting. When the system is operating properly, the lights on the circuit board are lit.

If the system fails to operate properly, all lights on the circuit board up to the one that

represents the component or system that has failed will be lit. For more detailed infor-

mation, refer to the Troubleshooting Guide in Paragraph 3.9..

Service: Replacing burned out bulbs is the only service required. If a bulb is not lit,

check the bulb by switching it with a bulb that is lit.

2. Remove the service panel and the junction box door. Disconnect the two-line

voltage power supply wires from the terminal block inside the junction box.

3. Disconnect the water feed line hose from the upstream side of the ball valve.

4. Unscrew the four sheetmetal screws holding the junction box to the cooling

module. Remove the junction box-pump-float switch assembly (See

FIGURE 8).

5. Dislodge the inlet basket screen from the pump and clean any buildup of debris

and dirt. Carefully remove the base cover plate from the bottom of the pump. Using

a mild soap solution, wash all deposits from the inside of the pump and remove all

debris from the impeller.

6. Reassemble the pump. Replace the parts in exact reverse order, being careful that

everything is returned to its proper position.