0 maintenance (cont'd), 3 maintenance procedures – Reznor ADFH Operation Manual User Manual

Page 4

Form O-ADF/RDF, P/N 148385R2, Page 4

The blower, motor and drive components are located in the blower cabinet. Remove

the panels required to access the component(s) being serviced.

Blower Bearings

All blowers are Class I with pillow block bearings. Clean the fitting and add type NLG-2

or -2 standard grade grease. Add grease with a handgun until a slight bead of grease

forms at the seal. Be careful not to unseat the seal by over lubricating.

CAUTION: If the blower is unused for more than three months, the

bearings should be purged with new grease prior to startup.

R

2.3.1 Drive Components

R

E

Blower Belts

Check belts for proper tension and wear. Adjust belt tension as needed. Replace worn

belts.

Proper belt tension is important to the long life of the belt and motor. A loose belt will

cause wear and slippage. Too much tension will cause excessive motor and blower

bearing wear. If adjustment is required, adjust belt tension by means of the adjusting

screw on the motor base until the belt can be depressed 1/2" to 3/4" (

FIGURE 1).

Tighten the lock nut on the adjusting screw. Be sure the belt is aligned in the pulleys.

FIGURE 1 - Belt Tension

2.3.2 Filters

If the system includes filters, check the filters quarterly.

To access the filters, remove the filter cabinet door panels. Clean or replace as needed.

If filters are removed, be sure the blockoff plates are returned to the filter rack.

3/4 (19mm)

S

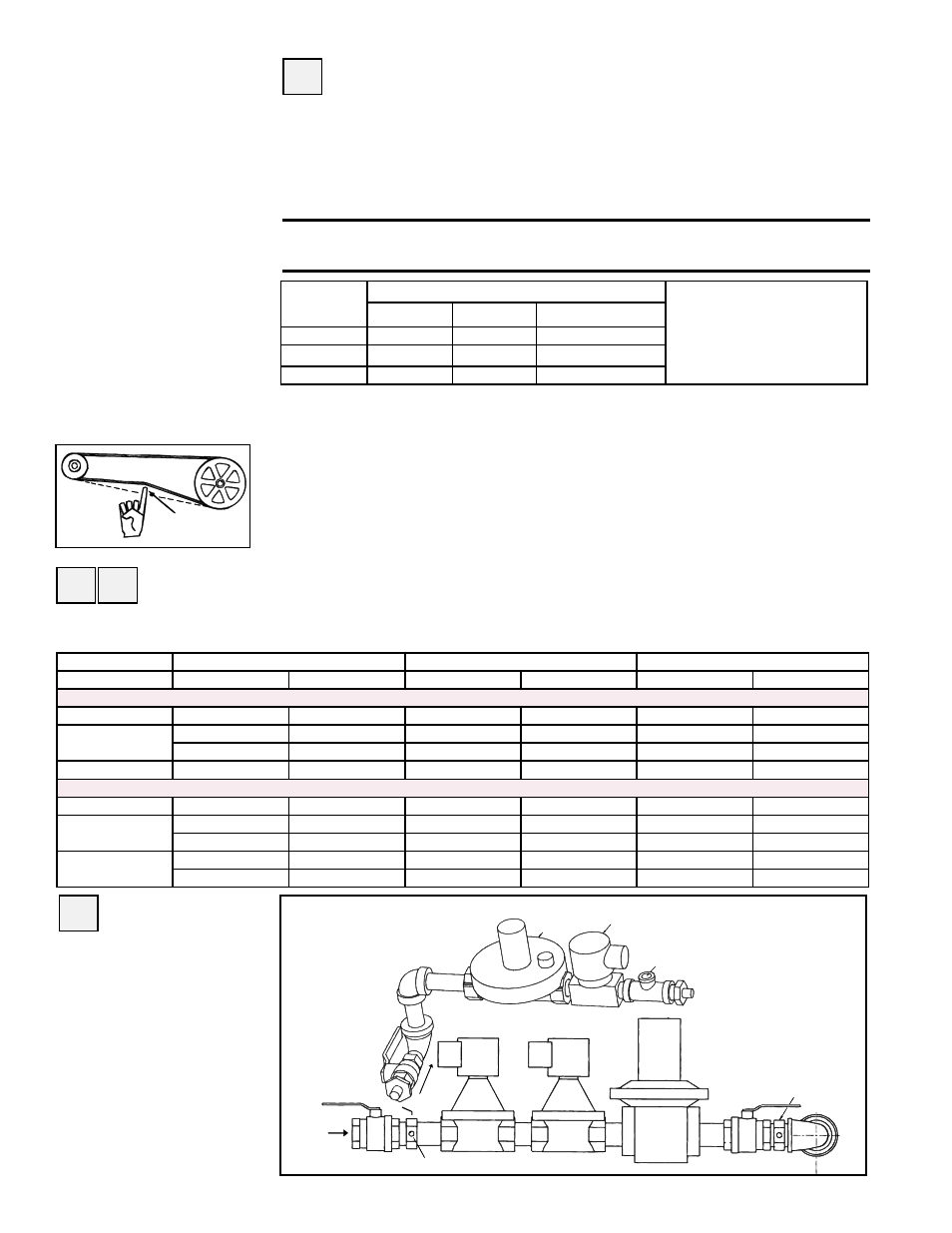

2.3.3 Manifold

Gas Pressure

Semiannually, check the

gas pressure to the burner

and to the pilot. Measure

both manifold pressure and

pilot supply pressure with

the blower in operation.

Verify against pressures

listed on the rating plate.

Recommended Bearing

Lubrication Schedule

in Months

Quantity and Size of Filters by Model

Inlet Pressure Tap

Valve

Valve

Regulator

Manifold Pressure Tap

Gas

Supply

Pilot

Regulator

Pilot Solenoid Valve

Pilot Pressure Tap

2.0 Maintenance

(cont'd)

2.3 Maintenance

Procedures

RPM

Range

Bearing Bore Diameter (Inches)

NOTE: If unusual

environmental conditions exist

(temperatures below 32°F or

above 200°F; moisture; or

contaminants) more frequent

lubrication is required.

1/2 to 1

>1 to 1-1/2

>1-1/2 to 1-15/16

to 1000

6 months

6 months

6 months

1001-1500

5 months

5 months

5 months

1501-2000

5 months

4 months

5 months

Type

Disposable

Permanent

Pleated Disposable

Thickness

1"

2"

1"

2"

1"

2"

Model RDF with Optional Filter Cabinet

1

-

-

(3)12x35

(4)12x35

-

-

2

-

-

(4)12x35

(4)12x35

-

-

-

-

(4)12x24

(4)12x24

-

-

3

-

-

(12)12x35

(10)12x35

-

-

Model ADF/ADFH with Optional Filter Cabinet

300

(5)12x30-5/8

(5)12x30-5/8

(10)10x16

(10)10x16

(5)12x32

(5)12x32

500

(5)12x20

(5)12x20

(5)12x20

(5)12x20

(5)12x20

(5)12x20

(5)12x25

(5)12x25

(5)12x25

(5)12x25

(5)12x26

(5)12x26

700, 1200

(5)12x25

(5)12x25

(5)12x25

(5)12x25

(5)12x25

(5)12x25

(5)12x30-5/8

(5)12x30-5/8

(5)12x32

(5)12x32

(5)12x32

(5)12x32

FIGURE 2 - Gas

Pressure Tap

Locations