0 maintenance (cont'd), 3 maintenance procedures (cont'd), 7 optional evaporative cooling module – Reznor ADFH Operation Manual User Manual

Page 6: 6 main burner and pilot assembly (cont'd)

Form O-ADF/RDF, P/N 148385R2, Page 6

2.3.7 Optional

Evaporative Cooling

Module

Media - Over time, excessive amounts of mineral deposits will begin to buildup on the

media. Annually, scale and dirt should be washed off the entering surface of the media.

Remove the pad retainers and screen. (See Steps 1-3 and 6-8 of Media Replacement

Instructions.) Clean the media using a garden hose, mild soap, and a soft bristled

brush. When the media becomes too clogged with mineral deposits and dirt that it can-

not be cleaned, the pads should be replaced. The average pad life is approximately

three cooling seasons.

See charts and

NOTE below for replacement media information. Follow the instruc-

tions and remove and replace pads as shown in

FIGURE 6.

R

E

Instructions

for Replacing

Evaporative Cooling

Media

1. Remove the three sheetmetal screws that hold the top pad retainer in place.

Release the top pad retainer from the cooling module.

2. Remove the three sheetmetal screws that hold the bottom pad retainer in place.

Release bottom pad retainer from the cooling module.

3. Disengage the screen retainers from the sides of the media.

4. Disengage inlet screen from media pads and remove.

5. Slide all media pads horizontally away from the cooling module until clear of

bottom reservoir pan. Dispose of properly.

2.0 Maintenance

(cont'd)

2.3 Maintenance

Procedures

(cont'd)

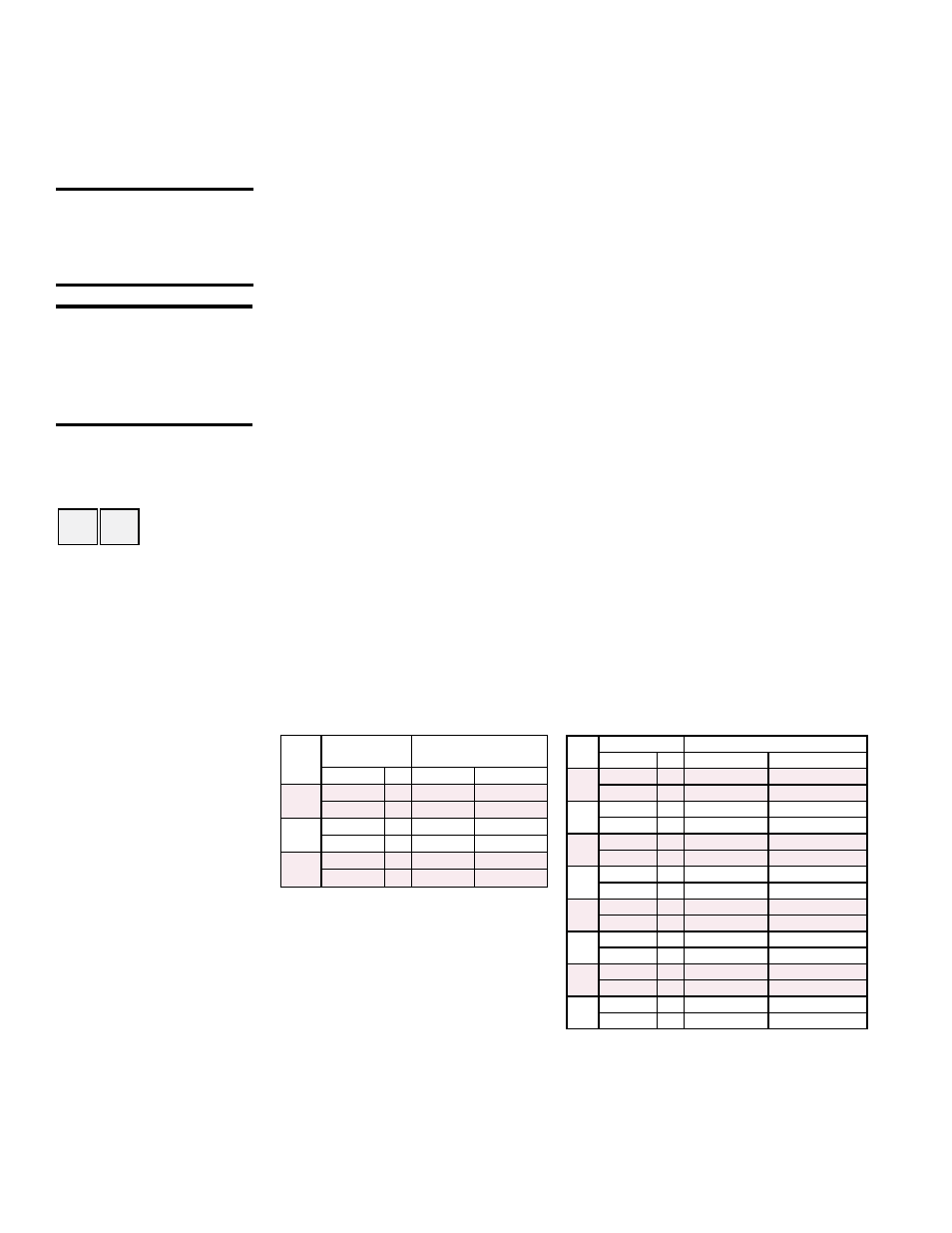

ADF /

ADFH

Media Pad

Size & Qty

Replacement P/N's

(each) - 12" media *

(inches) Qty Cellulose Glass Fiber

300

24 x 12

2

106021

106029

24 x 7-7/8 1

106022

106030

500

24 x 12

3

106021

106029

24 x 9-5/8 1

106025

106033

700/

1200

48 x 12

4

107194

107201

48 x 8-5/8 1

107195

107202

REC Media Pad

Replacement P/N's (each) *

Size

Qty 12” Cellulose 12” Glass Fiber

40

24x12

2

106021

106029

24x2-3/8 1

106022

106030

50

24x12

2

106021

106029

24x7-7/8 1

106023

106031

60

24x12

3

106021

106029

24x1-3/8 1

106024

106032

70

24x12

3

106021

106029

24x9-5/8 1

106025

106033

80

24x12

4

106021

106029

24x2-7/8 1

106026

106034

90

24x12

4

106021

106029

24x8-5/8 1

106027

106035

180

48x12

4

107194

107201

48x8-5/8 1

107195

107202

360

48x12

8

107194

107201

48x8-5/8 2

107195

107202

Evaporative Cooling Media -

Model ADF or ADFH with Option

AS3, AS4, AS5, or AS8

Evaporative Cooling Media - Model

RDF with attached Model REC

Evaporative Cooling Module

* NOTE: 6" media is no longer

available as a replacement part. Use

size to obtain media from a local

supplier.

2.3.6 Main Burner and Pilot Assembly (cont'd)

3) Disconnect the two ignition wires (male and female quick connections) and dis-

connect the flame sensor lead at the burner. Remove the setscrew located in the

ignitor tube (setscrew holds the brass bushing in place). Carefully remove the

brass bushing and the ignitor.

Check the hot surface ignitor for cracks or unusual deterioration. Check the flame

rod for integrity. Replace the flame rod (

P/N 134706) and/or the hot surface ignitor

(

P/N 121865) if not in good condition.

4) Clean the burner and pilot by back-flushing, using high pressure air (40-80 lbs).

Continue until dust particles are completely expelled from both the upstream and

downstream sides of the burner.

If air pressure does not unplug burner orifices or pilot tube, drill burner orifices with

a Size #50 drill and/or pilot tube with a Size #55 drill.

Inspect the upstream and downstream sides of the mixing plates. Remove any

accumulation of scale or foreign material with a wire brush. If any mixing plate fas-

teners are loose or missing, tighten or replace. Always use zinc plated or stainless

fasteners.

If any cracks are present, replace that mixing plate. Because of the effect of flame

temperature on the metal, fasteners may be difficult to remove. Be careful not to

damage the gaskets that go between the mixing plates and the burner body. The

gaskets are designed to overlap approximately 1/16" for airtight seal.

5) Follow Steps in reverse order to re-install the pilot assembly. Close all panels and

check for proper operation.

CAUTION: Wear eye

protection while

pressure cleaning

and drilling.

WARNING: Do not

enlarge burner ports

or performance

may be drastically

affected.