Component functions, Troubleshooting – Reznor R6GF Unit Installation Manual User Manual

Page 23

23

COMPONENT FUNCTIONS

Comfort Alert™ Diagnostics -The Comfort Alert

diagnostics module troubleshoots heat pump and air

conditioning system failures and accurately detects the

cause of electrical and system related failures without

any sensors. A flashing LED indicator communicates the

ALERT code to quickly direct the technician to the root

cause of a problem.

Flame Roll-Out Control - The flame roll-out control acts to

verify that the burner flame is being drawn into the heat

exchanger tubes. If the burner flame is not being drawn

into the heat exchanger tubes, the roll-out control will

open within several seconds and the integrated control

diagnostic light will flash one time. If the limit opens, the

integrated control diagnostic will flash one time. The

circulating air blower will continue to operate while the

flame roll-out control is open.

Flame Sensor - The flame sensor acts to prove that flame

has carried over from the ignitor to the right-most burner. If

no flame is sensed, the unit will be shut down automatically.

Dual Pressure Switch - The dual pressure switch verifies

that the inducer motor is drawing the combustion gases

through the heat exchanger tubes and venting the

gases through the vent system for both high and low fire

conditions.

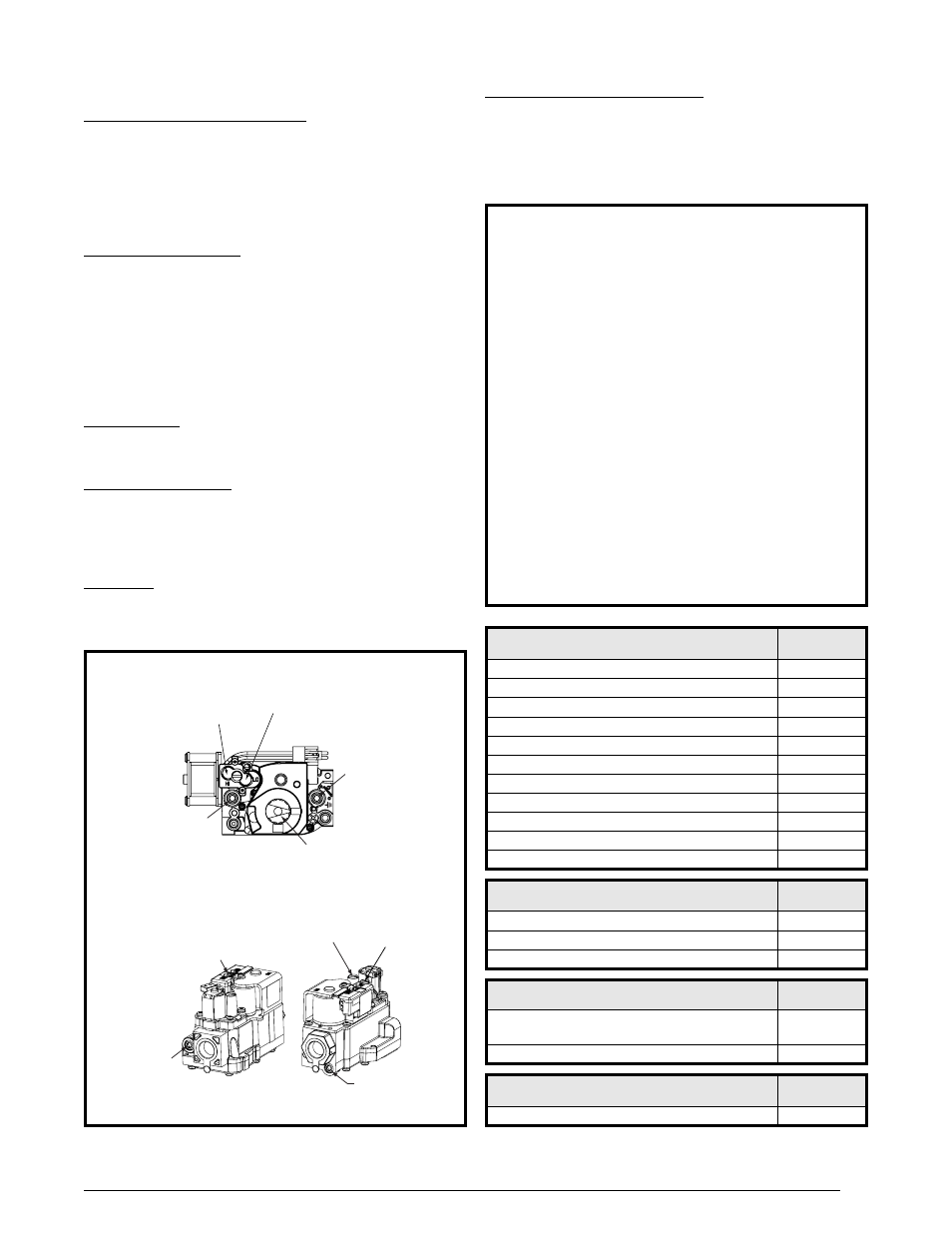

Gas Valve - The gas valve controls the flow of gas to the

burners in both low and high fire. When the gas valve is

energized it automatically opens and regulates the gas

pressure in the manifold. See Figure 8 below.

TROUbLESHOOTING

If the unit does not operate in the cooling mode, check

the following:

• The thermostat is operating properly

• Electrical power to the unit is turned on

• The filters are not dirty

• The service doors are in place

• The 5 amp fuse is operational

If the unit does not operate in the heating mode, check

the following:

• The thermostat is operating properly

• Electrical power to the unit is turned on

• The filters are not dirty

• The gas is turned on and the manual shut-off valve

is open

• The service doors are in place

• The flame roll-out control is closed

• The diagnostic codes listed in Table 7 or on the

wiring diagrams (Figures 11 or 12, pages 29 - 30).

• The 5 amp fuse is operational

Table 7. Ignition / Blower Control Diagnostic Codes

SYSTEM STATUS - IGNITION

LED STATUS

(RED)

Power On (Normal Operation)

ON

High Limit Circuit Open

1 Flash

Pressure Switch Open with Inducer On

2 Flashes

Pressure Switch Closed with Inducer Off

3 Flashes

Failed Ignition (5 attempts) - Control in 1 Hour Lockout

4 Flashes

208-230 Volt Polarity Issue

5 Flashes

Excess High limit trips (5) within one call for heat

6 Flashes

Excess pressure switch cycles (5) within one call for heat

7 Flashes

Excess flame dropouts (5) within one call for heat

8 Flashes

Not Used

9 Flashes

Flame present with gas valve Off

10 Flashes

SYSTEM STATUS - 2nd STAGE HEAT DEMAND

LED STATUS

(GREEN)

No demand for 2nd stage heat

OFF

2nd stage heat demand (Normal operation)

ON

2nd stage heat demand, high pressure switch not closed

Flashing

SYSTEM STATUS - HI/LO DEHUMIDIFY

(Cooling Mode only)

LED STATUS

(GREEN)

Factory jumper wire “R” to “DEHUM” in place or “Close

on Fall” humidistat (Low humidity) - Closed

ON

Humidistat open (High Humidity) Low Speed Blower call

OFF

SYSTEM STATUS - CFM

LED STATUS

(YELLOW)

NOT USED

OFF

IN

ON

OFF

Inlet

Pressure

Tap

Inlet

Pressure

Tap

Manifold

pressure

Tap

Manifold

pressure

Tap

2-STAGE GAS VALVES

Model VR8205Q2381

Model VR9205Q1028

ON / OFF

Knob

ON / OFF

Switch

HI Input

Adjusting Screw

Lo Input

Adjusting Screw

HI Input

Adjusting

Screw

Lo Input

Adjusting

Screw

Figure 8. HI & LO Input Adjusting Screws

Over-Temperature Limit Control - The over-temperature

limit control prevents the air temperature leaving the unit

from exceeding the maximum outlet air temperature. If the

limit opens, the integrated control diagnostic will flash one

time. The circulating air blower will continue to operate

while the over-temperature limit control is open.