Warning, Caution, Refrigerant charging – Reznor R6GF Unit Installation Manual User Manual

Page 19: Operating sequence, Heating mode

19

Refrigerant Charging

WARNING:

These units are shipped fully charged with

R-410A refrigerant and ready for installation.

When a system is installed according to these

instructions, no refrigerant charging is required.

If repairs make it necessary for evacuation and

charging, it should only be done by qualified,

trained personnel thoroughly familiar with this

equipment. Some local codes require licensed

installation/service personnel to service this

type of equipment. Under no circumstances

should the owner attempt to install and/or

service this equipment. Failure to comply with

this warning could result in property damage,

personal injury, or death.

CAUTION:

This unit uses R-410A refrigerant. DO NOT use

any other refrigerant in this unit. Use of another

refrigerant will damage the unit.

The system refrigerant charge can be checked and

adjusted through the service ports provided at the front

panel. Use only gauge lines which have a Schrader

depression device present to actuate the valve. Refrigerant

charging must be done by qualified personnel familiar with

safe and environmentally responsible refrigerant handling

procedures. Refer to the application notes and charging

charts on pages 33-35

Charging an R-410A unit in AC mode at

outdoor temperatures above 65F.

1. With the system operating at steady-state, measure the

liquid refrigerant pressure in psig at the service valve.

2. Measure the liquid refrigerant temperature in Fahrenheit

at the outlet of the condensor coil.

3. For the temperature measured, determine the required

liquid refrigerant pressure from the appropriate charging

charts in Figures 14 - 17 (pages 34 - 35).

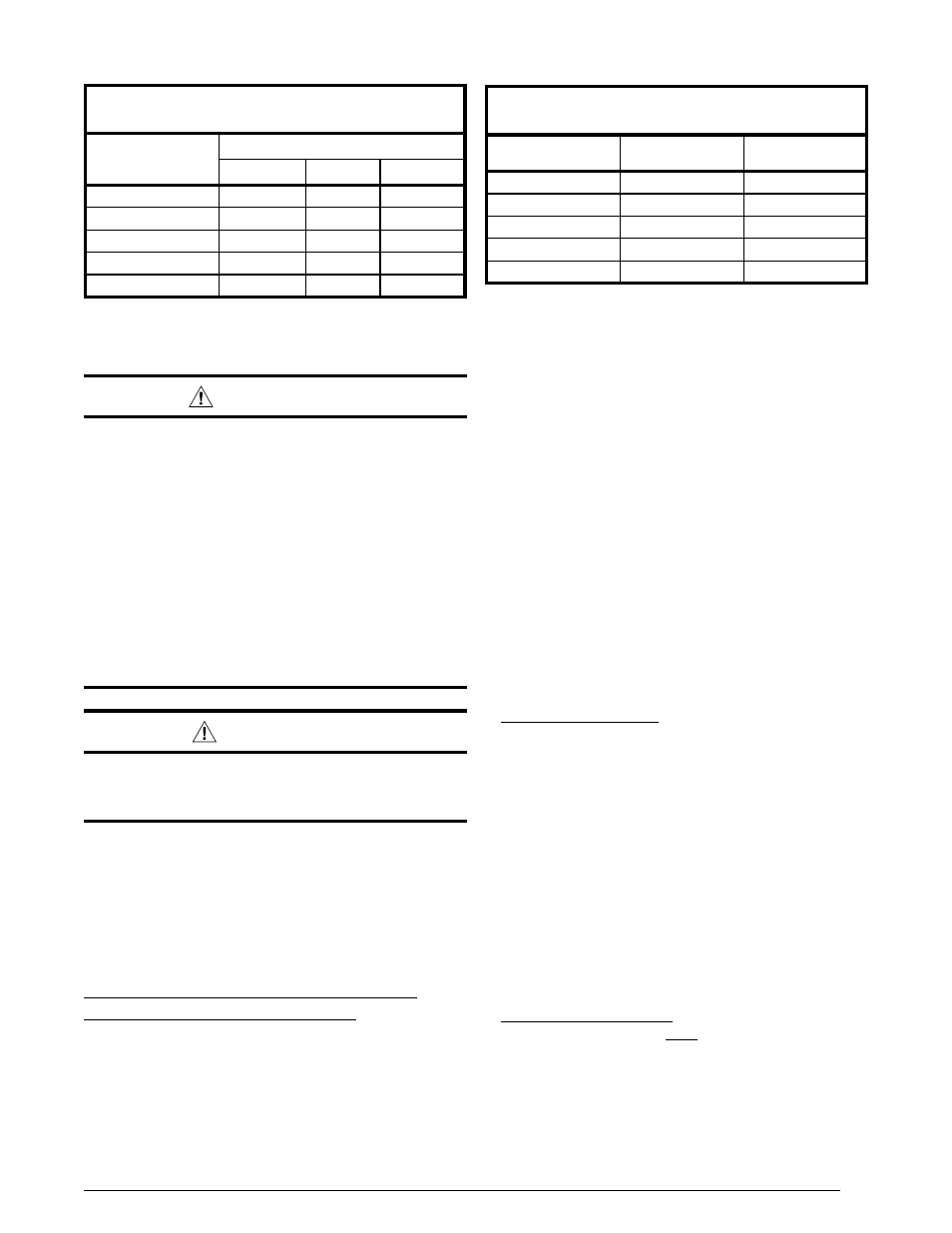

Table 5. Manifold Pressure (in W.C.) for Natural Gas

Manifold Pressure (in W.C.) for

Natural Gas Installations

Altitude above

sea level

Heating Value Btu/cu. ft.

800 to 899

900 to 999

1,000 to 1,100

zero to 1,999 FT

3.5

3.5

3.5

2,000 to 4,999 FT

3.5

3.5

3.5

5,000 to 5,999 FT

3.5

3.5

3.0

6,000 to 7,999 FT

3.5

3.2

2.8

8,000 to 10,000 FT

3.0

2.8

2.5

Table 6. Manifold Pressure (in W.C.) for LP Gas

Manifold Pressure (in W.C.) and Orifice Sizes

for LP/Propane Gas Installations

Altitude above

sea level

Manifold

Pressure

Orifice

Size

zero to 1,999 FT

10.0

55

2,000 to 4,999 FT

8.5

55

5,000 to 5,999 FT

10.0

56

6,000 to 7,999 FT

9.0

56

8,000 to 10,000 FT

8.5

56

NOTE: Manifold pressure based on sea level LP heating value

of 2,500 Btu/cu. ft.

3

4. If the pressure measured in step 1 is greater than the

required liquid refrigerant pressure determined in step

3, then there is too much charge in the system. Remove

refrigerant and repeat steps 1 through 3 until the system

is correctly charged.

5. If the pressure measured in step 1 is less than the

required liquid refrigerant pressure determined in step

3, then there is too little charge in the system. Add

refrigerant and repeat steps 1 through 3 until the system

is correctly charged.

OPERATING SEQUENCE

The operating sequences for the heating, cooling, and

fan modes are described below. Refer to the field and

furnace wiring diagrams (Figures 12 or 13, pages 29 - 30).

Heating Mode

1. On a call for 1st stage heat, the thermostat closes and

applies 24 VAC to terminal W on the control board.

2. Safety Circuit Proving - The control board verifies

continuity through the 24VAC limit control circuit. If the

high temperature limit switch and flame roll-out switch

are closed and both the high and low vent pressure

switches are open, the control board will then begin

pressure switch proving. If an open limit is detected, the

control board will energize the indoor blower motor and

operate it continuously while the limit switch circuit is

open. All other system functions will be inoperable until

the limit circuit closes. While the limit circuit is open, the

control will flash 1 on the red LED.

3. The furnace control checks for continuity (24 VAC)

across the pressure switch. If the pressure switch is

closed, the heat mode sequence will not continue. If it

remains closed for 10 seconds, the red LED will flash

3 times repetitively until the fault condition clears.

4. Pressure Switch Proving - The control energizes the

induced draft motor on High speed and waits for the

low pressure vent switch to close. If the low pressure

switch does not close within 60 seconds, the control

will flash 2 on the red LED. If the low pressure switch

does not close before 60 seconds expires, the control

will de-energize the inducer for 60 minutes and continue

to flash 2 during the 60 minute inducer off period. After