Thermostat demand wiring, L terminal wiring, Dc sol connection – Reznor R6GF Unit Installation Manual User Manual

Page 13: Optional humidistat, Optional comfort alert, Diagnostics module, 24 vac power wiring

13

due to safety controls, defrost boards, or other control

boards which could lead to nuisance alerts.

Thermostat Demand Wiring

The Comfort Alert module requires a two stage thermostat

to operate properly. The Y2 thermostat wire entering the

outdoor unit should be connected to the Y2 input on the

unit terminal strip.

While the compressor is running, Comfort Alert will provide

power to the second stage cooling solenoid inside the

compressor after Y2 has been energized for 5 seconds.

When the compressor is not running, Comfort Alert will

not power the solenoid, regardless of the state of Y2. If

Alert codes 1 or 9 appear while the compressor is running,

Comfort Alert will turn off the solenoid to prevent solenoid

damage from overheating conditions.

L Terminal Wiring

White-Rodgers Compatible Thermostats - The L

connection is used to communicate Comfort Alert codes

to compatible White-Rodgers thermostats. The L terminal

of these thermostats should be connected to the Comfort

Alert L terminal. See unit wiring diagram label included

on the unit or in these instructions for correct field wiring

connections.

NOTE: On some White-Rodgers combatible thermostats,

an icon on the thermostat display will flash at the same rate

as the Comfort Alert yellow Alert LED. An advanced option

on these thermostats is to lock out the compressor when

certain Alert codes are detected in indicating impending

compressor damage. Refer to White-Rodgers thermostat

manuals for more information.

Standard Non-Compatible Thermostats

– The

L

connection on non-compatible type thermostats are used

for heat pump defrost control board fault monitoring. The L

terminal of these thermostats should be connected directly

to the defrost control board L terminal. See the wiring

diagram label or the heat pump installation instructions

for correct field wiring connections.

DC SOL Connection

The two pin DC SOL connector provides a connection to

the Copeland UltraTech second stage compressor solenoid

(Figure 13, page 28). This 24VDC solenoid is internal to

Optional Humidistat

An optional humidistat may be installed in the return

air duct for humidity control (when needed), maximum

system capacity and energy efficiency. The humidistat

senses when humidity in the return air stream is above

a preset level and sends a signal to the motor to reduce

airflow. This allows more moisture to be removed until

the humidity level drops. NOTE: The indoor blower motor

of this packaged unit is pre-programmed for humidistat

operation. Remove the Red jumper wire between the R

and DEHUM terminals on the ignition control board.

If installing a humidistat, install it in the return air duct

as directed in the installation instructions included with

the kit. Wire the humidistat through the low-voltage wire

entrance in the packaged unit to the screw terminals

marked R & DEHUM.

Wire the humidistat to open on

rise in humidity.

When the HI/LO Dehumidify Green LED status light is

ON, it signals Low Humidity and keeps 24V supplied to

the motor for normal airflow requirements. If the humidity

level of the conditioned space increases the humidistat

will open. Loss of the 24V signal to the indoor blower

motor allows the motor to reduce to approximately 75%

of normal airflow selected until the humidity level drops.

The Green LED is OFF during high humidity conditions.

See Figure 11B (page 28).

Check all factory wiring to the units wiring diagram. Inspect

the factory wiring connections to be sure none loosened

during shipping or installation.

Optional Comfort Alert

TM

Diagnostics

Module

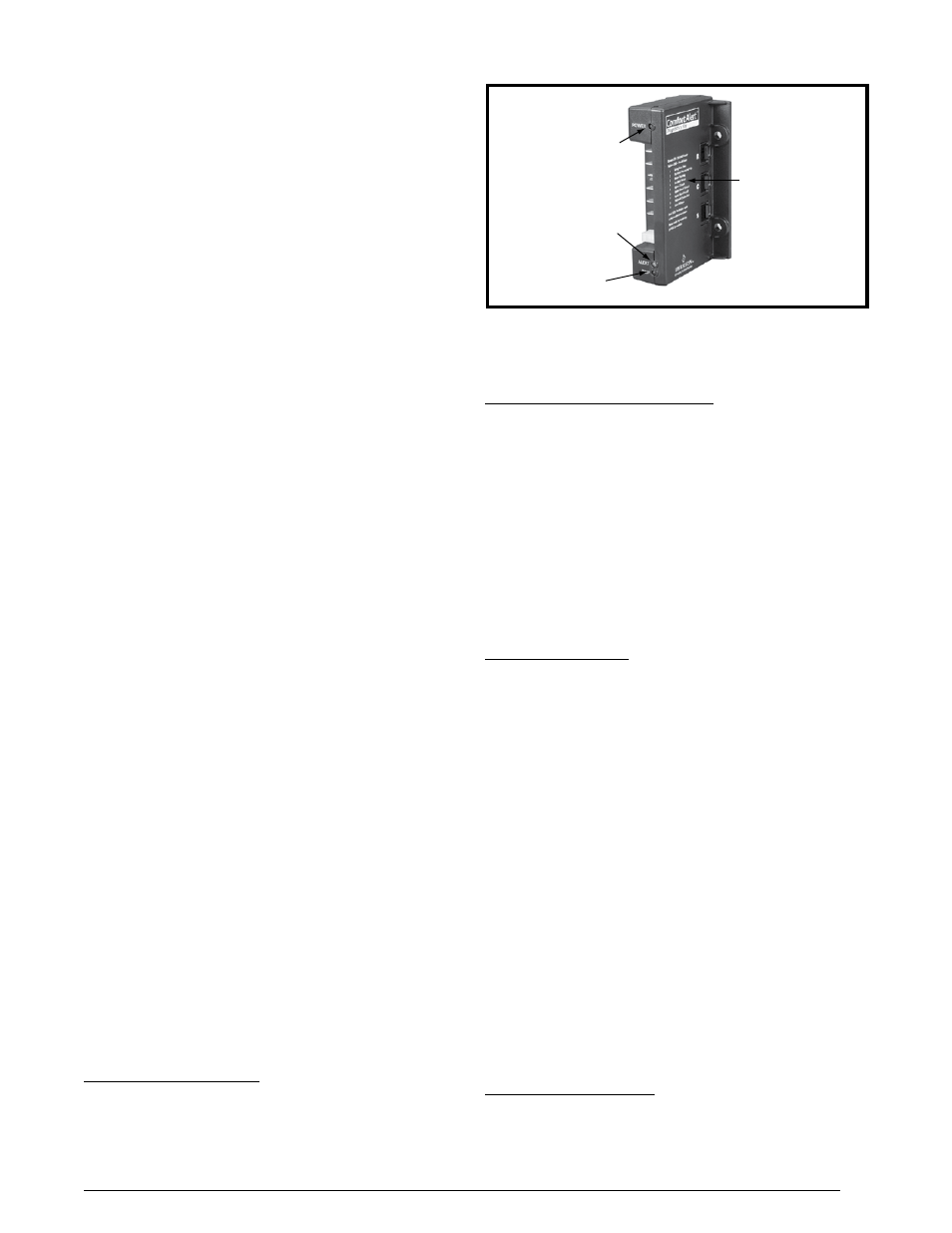

The Comfort Alert

TM

Diagnostics Module is a breakthrough

innovation for troubleshooting heat pump and air

conditioning system failures. The module installs easily in

the electrical box of the outdoor unit near the compressor

contactor. By monitoring and analyzing data from the

Copeland scroll compressor and the thermostat demand,

the module can accurately detect the cause of electrical

and system related failures without any sensors. A

flashing LED indicator communicates the ALERT code

and a diagnostic key is also imprinted on the side of the

module to quickly direct the technician to the root cause

of a problem. See Figure 6.

NOTE: This module does not provide safety protection!

The Comfort Alert

TM

Diagnostics Module is a monitoring

device and cannot control or shut down other devices.

24 VAC Power Wiring

The Comfort Alert

TM

module requires a constant nominal

24 VAC power supply. The module should be powered by

an R & C that doesn’t have the potential for loss of power

nominal rise based on the furnace’s nominal efficiency

and firing input. Follow across the table row to find the

tap setting and nominal air-flow. Verify the selected rise is

within the specification shown on the furnace rating label.

Figure 6. Comfort Alert

TM

Diagnostics Module

POWER LED

(Green)

TRIP LED

(Red)

ALERT LED

(Yellow)

Diagnostics

Key