0 maintenance and service, 0 commissioning and startup (cont’d), Inlet and exhaust components – Reznor MAPS IV Option - Installation - Energy Recovery Module Installation User Manual

Page 8: Energy recovery wheel

I-MAPSIII&IV-ER, PN262634R3, page 8

10.0 Maintenance

and Service

Exhaust Filters

Inlet Air Filters

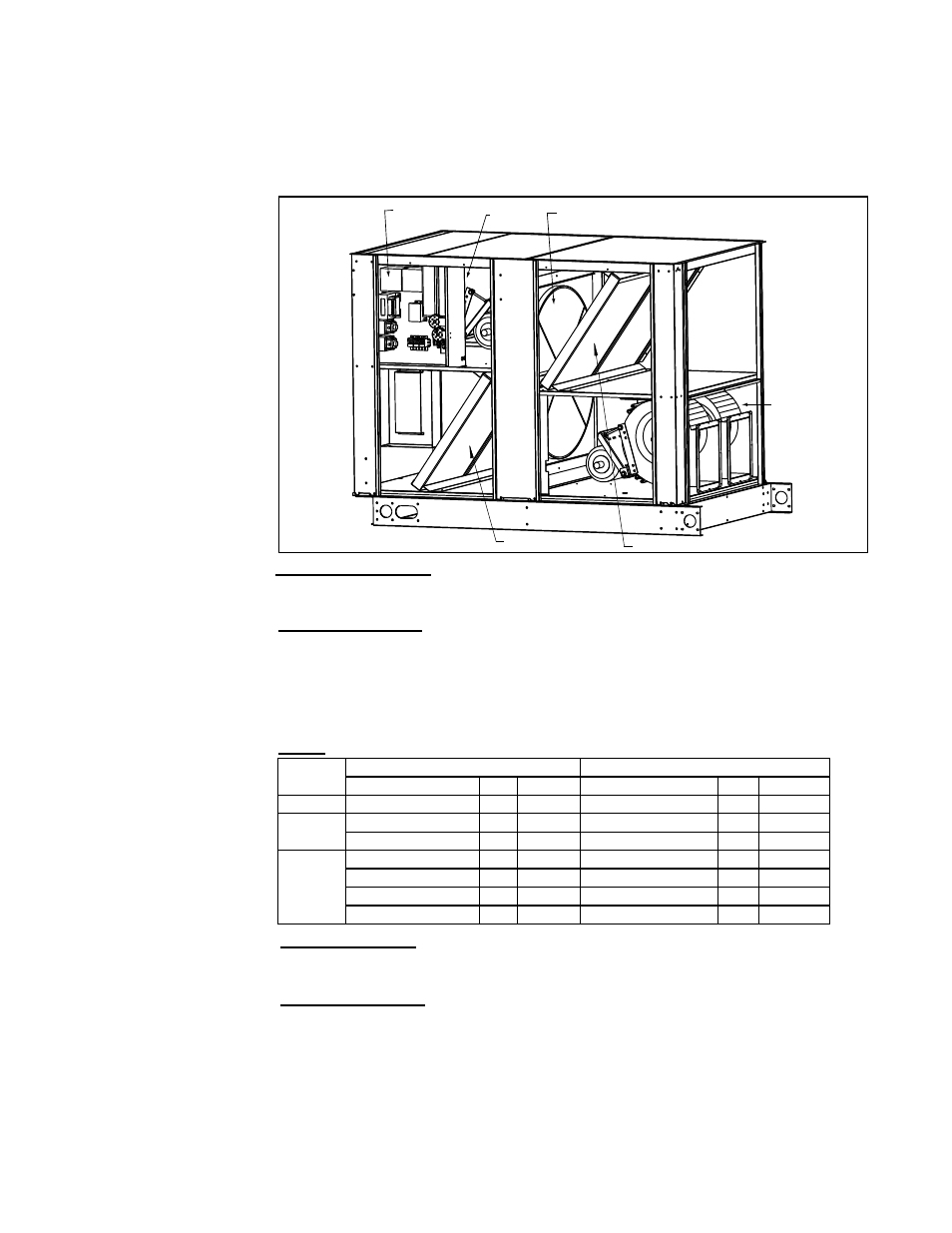

Energy Recovery Wheel - To access: (1) Remove center post;

(2) Disconnect motor wiring; (3) Slide out wheel cassette.

Exhaust

Fan(s)

Supply

Fan(s)

Control

Compartment

Center Post

(Remove to slide out the

wheel cassette.)

(Outside cabinet -

Location of

outside air hood

with cleanable

filters.)

(Inside

cabinet -

Location of

optional inlet

dampers.)

(Location of

gravity dampers

and exhaust

hood.)

(This end

connects

to the inlet

of a MAPS®

III or IV unit.)

Energy Recovery

Module with Panels and

Hoods Removed

Inlet and Exhaust

Components

Blowers and Drives - The blowers (supply and exhaust fans) have permanently lubri-

cated cartridge ball bearings and do not require greasing.

Check the condition and tension of the belts. Belt tension should allow a 3/4” depres-

sion of the belt. See belt tension in Paragraph 8.0. If the belt needs to be replaced, use

a factory-authorized replacement.

Check the setscrews; see Paragraph 8.0.

Energy Recovery

Wheel

Check Wheel RPM - The wheel should rotate slowly at approximately 53 rpm. If rota-

tion is not normal, see the wheel maintenance information that follows. Perform service

as needed and/or replace any defective parts.

Wheel Maintenance - The energy recovery wheel cassette is designed to be slid out

of the unit for inspection and cleaning. Follow the instructions in

the illustration on

page 7 and the cleaning instructions below.

How often the wheel needs to be cleaned depends on its environment. Because the

wheel rotates between two opposing airstreams, it is self-cleaning of most dry dirt and

dust and will remain efficient for a long period of time. However, when the wheel is

exposed to oils, tars, or greases in either the supply or exhaust airstream, the surface

will become “sticky” and will hold the dirt and dust. Over time the air passages will

become blocked causing loss of recovery, excessive pressure drop, and loss of energy

savings.

Filters - Check inlet and exhaust filters. Replace as needed.

Cabinet

Size *

Inlet Air Filters (Merv 8)

Exhaust Air Filters (Merv 8)

Filter Type & Size

Qty

P/N

Filter Type & Size

Qty

P/N

A

Pleated 20x25x2

2

104113

Pleated 20x25x2

2

104113

B

Pleated 16x25x2

2

104112

Pleated 16x25x2

2

104112

Pleated 12x25x2

2

114320

Pleated 12x25x2

2

114320

C

Pleated 16x25x2

2

104112

Pleated 16x25x2

2

104112

Pleated 20x25x2

2

104113

Pleated 20x25x2

2

104113

Pleated 16x16x2

1

104109

Pleated 16x16x2

1

104109

Pleated 16x20x2

1

104110

Pleated 16x20x2

1

104110

*See cross-reference of

MAPS

®

Models by Cabinet

Size A, B, or C on page 11.

Hoods and Dampers - Clean the filters in the outside air hood. If there is an inlet

damper, carefully remove dirt from the damper blades. Clean gravity relief damper

blades at the exhaust outlet.

□

If equipped with dirty filter switch (Option BE28), set the switch. See Paragraph

6.0.

□

After at least 8 hours but no longer than a week of operation, recheck the supply

and exhaust fan components -- blower wheels including all set screws, blower

pulleys, motor pulleys, and belt tension. Make any required adjustments. See

instructions and requirements in Paragraph 8.0.

9.0 Commissioning

and Startup

(cont’d)

Checks after Startup (cont’d)