0 maintenance and service (cont’d), Energy recovery wheel (cont’d) – Reznor MAPS IV Option - Installation - Energy Recovery Module Installation User Manual

Page 10

I-MAPSIII&IV-ER, PN262634R3, page 10

Energy Recovery

Wheel (cont’d)

Checking

the Seals

Check Wheel Drive Components

Motor - The motor bearings are pre-lubricated and do not need additional lubrication. Clean any dirt from the air cooling

ports in the motor housing.

Pulley - The pulley is secured to the drive motor shaft by a set screw. The set screw is secured with removable Locktite

to prevent loosening. Confirm the set screw is secure.

Belt - The belt is of urethane stretch material and is designed to provide constant tension. There is no type of adjust-

ment. Inspect the belt for proper tracking and tension. If a belt needs replaced, it must be replaced with a factory-

authorized replacement (see P/N’s below). Follow the wheel manufacturer’s instructions.

NOTE: A properly tensioned belt will turn the wheel immediately after power is applied with no visible slippage during

startup. The belt should track approximately 1/4” from the outer edge of the rim.

If the belt or any other component needs replaced, use only factory-authorized replacement designed for the purpose.

Follow instructions provided by the wheel manufacturer.

Wheel Replacement Parts

*See cross-reference of

MAPS

®

Models by Cabinet

Size A, B, or C on page 11.

10.0 Maintenance

and Service

(cont’d)

d) Repeat the procedure on the other three seals.

2. When the unit is started, start and stop the wheel several times to verify seal

adjustment and to confirm that the belt is tracking properly on the wheel rim. The

belt should be approximately 1/4” from the outer edge of the rim.

Part

Cabinet A *

Cabinet B *

Cabinet C *

Belt

262488

262489

262490

Wheel

Motor

115V, 1050

rpm

- 262494

200-230/480/3, 800 rpm

- 262491 200-230/480/3, 1075 rpm - 262492

575V, 1075 rpm -

262493

575V, 1075 rpm -

262493

Wheel

Segment

(1)

262495

(1)

262497

(1)

262499

(4)

262496

(6)

262498

(6)

262500

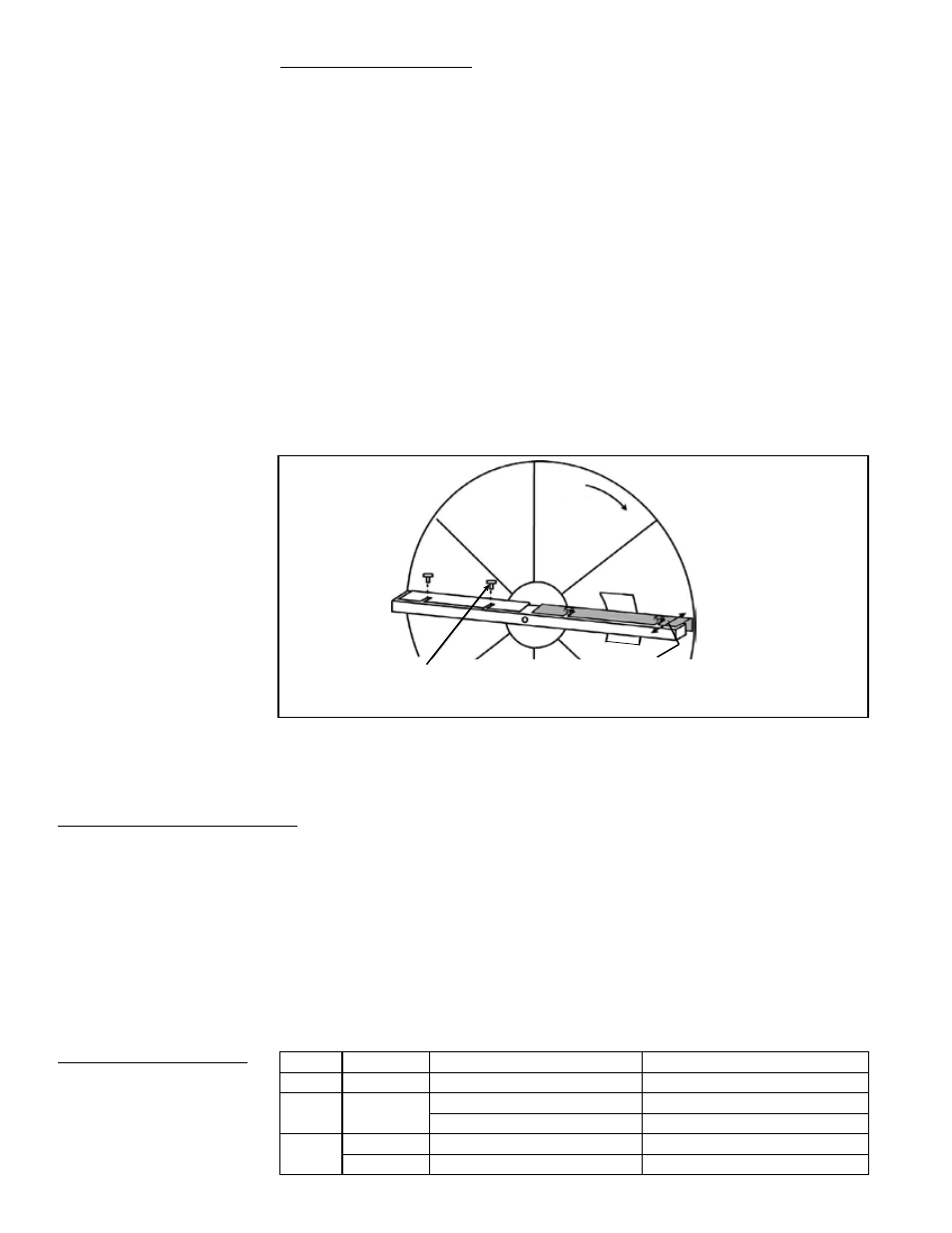

Checking the Wheel Seals - The seals are on the center support that goes across the

diameter of the wheel. There are two seals on each side of the wheel with one seal on

each side of the hub. Seals are metal strips with insulation on the surface closest to the

wheel. The purpose of the seals is to minimize the transfer of air between the counter

flowing airstreams.

After any wheel service and during maintenance, check the seal adjustment. Adjusting

the seals will require a screwdriver and a piece of paper.

1. If the wheel has not been removed from the cabinet, follow the steps in the

illustration on page 7 to remove the cassette.

Each seal strip has adjustable retaining screws that allow the insulation to move

toward or away from the wheel. Refer to the illustration below, and follow the

instructions below to adjust the seals.

a) On one seal, loosen the seal retaining screws just enough to slide the

seal strip.

b) Fold the piece of paper to use as a feeler gauge. Position the folded

paper between the wheel surface and the seal. Turn the wheel so that

the seal is lined up with a segment spoke.

c) Adjust the seal toward the wheel surface and slide the feeler gauge

(folded paper) along the length of the spoke. When a slight friction

is detected on the feeler gauge (folded paper), tighten the screws.

Recheck the clearance with the feeler gauge.

Wheel

Rotation

Folded Paper

Feeler Gauge

Seal

Seal

Adjusting Screws

(When adjusting

seal, loosen only;

do not remove.)

Slide seal (shown in gray) toward wheel

until a slight friction on the feeler gauge

is detected when gauge is moved along

the length of a spoke. Repeat with all seals.