0 blowers, belts, and drives, Energy recovery (enthalpy) wheel (cont’d) – Reznor MAPS IV Option - Installation - Energy Recovery Module Installation User Manual

Page 6

I-MAPSIII&IV-ER, PN262634R3, page 6

The energy recovery module has both a supply fan and an exhaust fan. The supply fan

blower is matched to the airflow range through the energy recovery wheel and must

be checked after the blower on the MAPS

®

unit is set. (Follow the instructions in Para-

graph 9.0.) The exhaust fan is selected to match the MAPS

®

cabinet size.

Each fan system is equipped with a 1 to 5 HP motor and linked belt drive. Depending

on motor type, motor size, and option selection, control may be by either contactor,

starter, or factory-installed VFD.

8.0 Blowers, Belts,

and Drives

Belts and Belt Tension - The supply and exhaust blower systems are equipped with

Power Twist Plus linked blower belts. The linked belts are designed in sections allow-

ing for easy sizing and adjustment. The belt is sized at the factory for the proper ten-

sion. Check belt tension. Proper belt tension is important to the long life of the belt and

motor. A loose belt will cause wear and slippage. Too much tension will cause exces-

sive motor and blower bearing wear. The belt tension should be checked after the first

24 hours of running at full load and at regular maintenance inspections.

If a linked belt needs tightening, the recommended method of tightening the belt length

is to count the number of links and remove one link for every 24. (A link is made up of

two joining sections of belt. For easier removal of links, turn the belt inside out. But be

sure to turn it back before installing. If a belt is removed or replaced, be sure to align

directional arrows on the belt to the proper drive rotation.)

3/4 (19mm)

Belt Tension

WARNING: All

setscrews and

locking collars must

be tightened before

applying power.

Pulley/Shaft Setscrews -

Wrench torque 110 in-

lb minimum to 130 in-lb

maximum.

Bearing Hub - Socket size

5/16"; Torque 165 in-lbs.

Blower Rotation - Each blower housing is marked for proper rotation. Check blower

rotation with the arrow on the housing. If actual rotation is not correct, interchange the

two wires on the 3-phase supply connections at the terminal block. Do not change load

side wiring.

Exhaust

Air

Inlet

Air

Energy

Recovery

Wheel

Inlet

Air Bypass

Exhaust

Air

Bypass

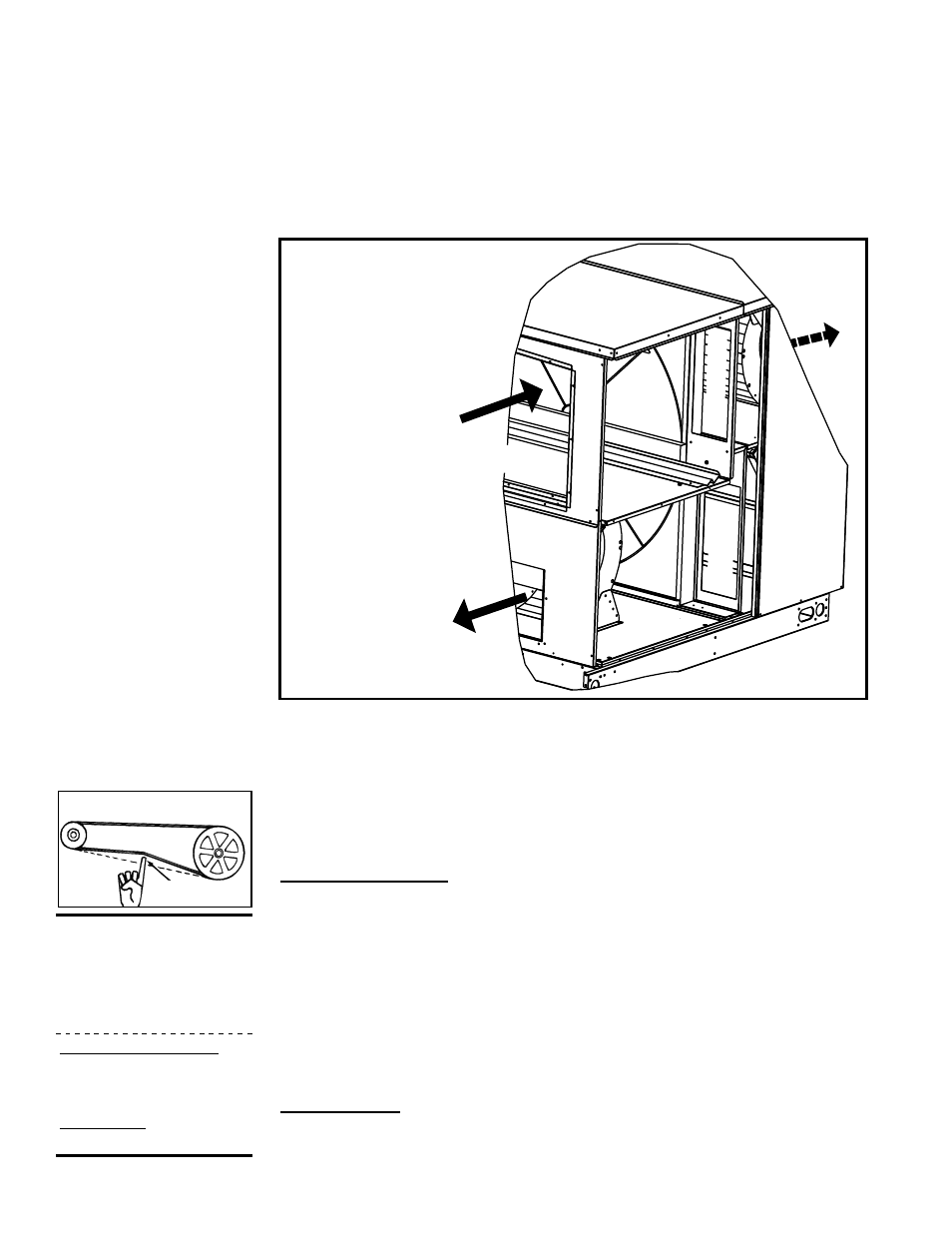

NOTE: Inlet filters

removed for clarity.

(Maps

Unit)

Bypass Air Opening Locations

(Shutter is not shown,

but if required, a shutter

is vertical in each opening.

Panels are removed here

for visibility.)

7.0. Energy

Recovery

(enthalpy)

Wheel (cont’d)

exhausted without going through the wheel. The purpose of the bypass is to increase

the load on the coils for improved coil performance and/or additional reheat capacity.

On some units, the bypass adjustment also allows for a higher supply and exhaust air

volume capacity.

Adjustable shutters allow the width of the bypass openings to be factory set to provide

the percentage of bypass air needed as determined from the specifications provided

on the order. If installation requirements change or if the bypass shutters are mistak-

enly moved, contact the factory or Reznor

®

representative for field adjustment. The

original order information and any changes in specifications must be provided.

NOTE: Option

ER1 energy

recovery modules

manufactured prior

to 4/12 do not have

adjustable shutters on

the bypass openings.