Energy recovery (enthalpy) wheel, Frost prevention control dirty filter switch – Reznor MAPS IV Option - Installation - Energy Recovery Module Installation User Manual

Page 5

I-MAPSIII&IV-ER, PN262634R3, page 5

Outside

Air

(MAPS® unit)

Option AR2J

on Energy

Recovery

Module

(Option ER1)

Cabinet

A, B, or C

with Option

ER1

Exhaust Air

(Energy

Recovery

Module)

Outside

Air

(MAPS® unit)

Option AR2L

on Energy

Recovery

Module

(Option ER1)

Cabinet A, B, or C

with Option ER1

Cabinet A, B, or C

with Option ER1

Exhaust Air

(Energy

Recovery

Module)

Outside

Air

(MAPS® unit)

Option AR2K

on Energy

Recovery

Module

(Option ER1)

(Energy

Recovery

Module)

Return /

Exhaust Air

Gravity

Exhaust

Damper

Gravity

Exhaust

Damper

Gravity

Exhaust

Damper

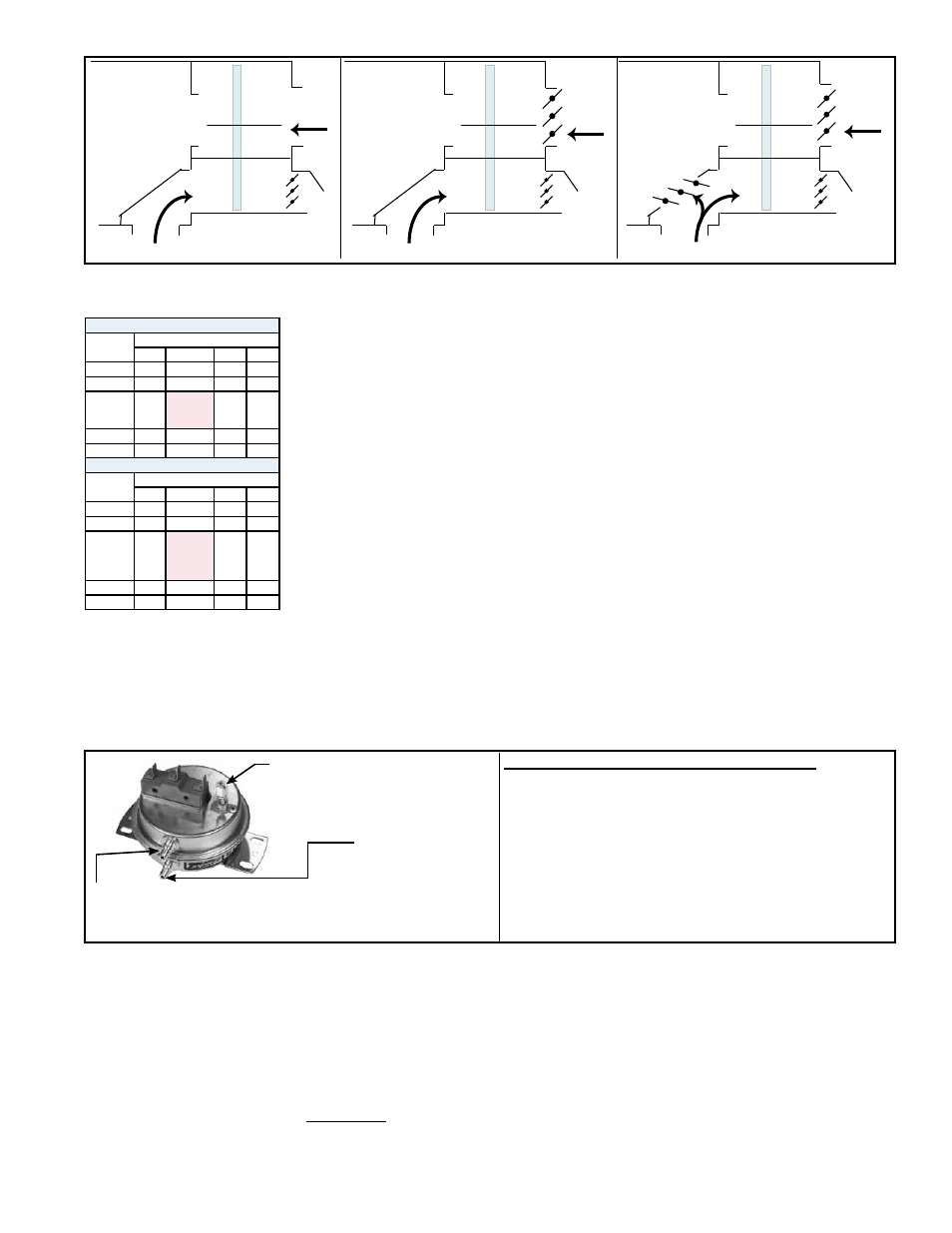

100% Outside Air

with Motorized

Damper in ER

module interlocked

with unit blower

start

Outside Air &

Return Air with

interlocked Motor-

ized Dampers -

requires control

Option GF2

or GF7

Frost Threshold Temperatures (°F)

Indoor Air

R.H. %

Indoor Air Dry Bulb Temperature

70° F

72° F

75° F 80° F

20

-14

-13

-11

-8

30

-3

-2

-1

3

40

5

7 (default

without

Opt BE6)

9

11

50

12

13

15

18

60

18

19

21

26

Frost Threshold Temperatures (°C)

Indoor Air

R.H. %

Indoor Air Dry Bulb Temperature

21° C

22° C

24° C 27° C

20

-26

-25

-24

-22

30

-19

-19

-18

-16

40

-15

-14

(default

without

Opt BE6)

-13

-12

50

-11

-11

-9

-8

60

-8

-7

-6

-3

Frost Prevention

Control

Dirty Filter Switch

Setscrew (on front of switch)

must be manually adjusted

after the system is in

operation.

Negative pressure connection is

toward the "front or top" of the

switch (senses blower side of filters)

Positive pressure

connection is

toward the "back

or bottom" of the

switch (senses air

inlet side of filters)

Instructions for Setting Dirty Filter Switch (located

in the control compartment) - With clean filters in

place; all doors closed (except electrical compartment);

and the blower operating, increase the pressure setting

by adjusting the setscrew on the switch clockwise until

the filter light is energized or the screw is bottomed

out. At that point, adjust the setscrew three full turns

counterclockwise or until the screw is top-ended. At that

setpoint, the filter light will be activated at approximately

50% filter blockage.

All Option ER1 energy recovery modules have a built-in frost prevention sequence.

The frost prevention sequence monitors the outside air temperature, and when the

outside air temperature falls below 7°F (-14°C), the controller implements a wheel

start/stop/jog sequence to prevent frost buildup. Frost will not damage the wheel but

will plug the wheel reducing airflow. The default setpoint of 7°F (-14°C) assumes a

return air design condition with a maximum temperature of 72°F (22°C) at 40% RH as

shown in the table (left). If making a setpoint adjustment, the user must adjust based

on the design conditions shown in the table. Once the outside air is 3°F (2°C) above

the setpoint, wheel operation returns to normal.

If Option BE6 was ordered, in addition to monitoring the outside air temperature, a

factory installed return air temperature and humidity sensor is used to calculate the

frost threshold point and initiates the frost prevention sequence when the outside air

falls below the calculated frost threshold temperature. (Frost threshold temperature is

the point at which frost begins to accumulate on heat exchanger surfaces. It is a func-

tion of both outside air temperature, indoor temperature, and indoor relative humidity.)

With Option BE6, the energy recovery wheel controller monitors the return air tempera-

ture, return air humidity, and outside air conditions and determines the frost threshold

based on the chart (left). Frost prevention is not required until outdoor air temperature

is below the threshold. When the outside air temperature is below the frost threshold,

the controller implements a wheel start/stop/jog sequence to help prevent frost buildup.

Once the outside air temperature is 3°F (2°C) above the calculated frost threshold,

wheel operation returns to normal.

If Option BE28 was ordered, a pressure switch (P/N 105507) senses pressure through

the supply filters. When the setpoint is reached, a signal is sent to the IQ to provide a

“dirty filter alert”.

7.0. Energy

Recovery

(enthalpy)

Wheel

The energy recovery wheel rotates through both the inlet and exhaust airstreams. The

function of the wheel is to transfer both sensible (temperature) and latent (moisture)

energy from one airstream to the air in the other airstream. This allows the energy

recovery module to both cool and dehumidify outdoor makeup air during the cooling

season and heat and humidify outdoor makeup air in the heating season before that

air enters the MAPS

®

unit.

The wheel is rotated by a motor and non-adjustable belt drive. The speed of the rota-

tion is factory set to provide optimum energy transfer.

Bypass Air - Both the inlet and exhaust airstreams have a bypass opening. Depending

on the requirements of the installation, a percentage of filtered outside air is allowed to

enter the MAPS

®

unit without going through the wheel and a percentage of return air is