0 electrical connections, 0 adjust water flow over media, Ball valve – Reznor REC (Evaporative Cooling) Unit Installation Manual User Manual

Page 8

Form I-REC, P/N 16021R3, Page 8

4.0 Electrical

Connections

All electrical wiring and connections, including electrical grounding, must be made in

accordance with the National Electric Code ANSI/NFPA No. 70 (latest edition) or, in

Canada, with the Canadian Electrical Code, Part I-CSA Standard C22.1. In addition,

compliance must be made with any local ordinances and any electric or gas company

requirements that might apply. Consult with local authorities having jurisdiction to verify

local codes and installation procedures.

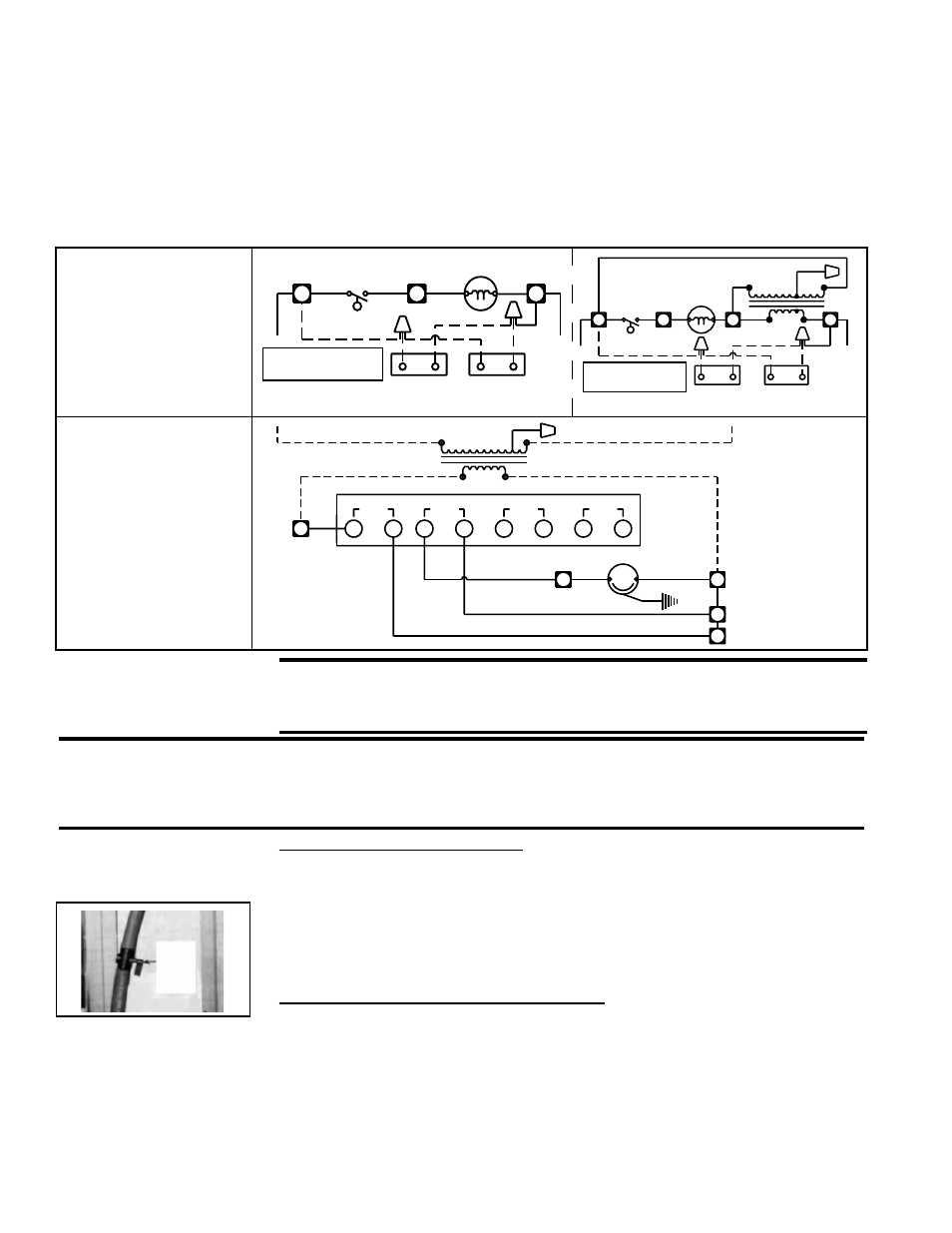

The wiring diagrams in

FIGURE 10 illustrate the factory-wired connections in the cool-

ing module junction box. Dashed lines are field-wired.

Use the two electrical snap bushings provided to protect the tubing-encased wires

when making connections to the field-supplied air moving equipment.

COOLING CIRCUIT

W.D. 188033

40 VA. AQUA SAVER

AQUA SAVER

24

VAC

H

R

BR

BR

VALVE

SOLENOID

MPR WATER CONTROL

BR

B

SUPPLY

BR

B

VALVE

24V

LINE VOLT

R

BR

BR

J

J

SOLENOID

DRAIN

VALVE

Z

R

VALVE

TRANSFORMER

GRD

G

R

R

J

Model REC with

AquaSaver Timed

Metering Control

System, Option

ECD1

V

W

PUMP MOTOR

LINE VOLT

SWITCH

FLOAT

W

B

H

B

J

Y

N.O. TWO WAY

DRAIN VALVE

FILL VALVE

THREE WAY

OPTIONAL

OPTIONAL

Y

115-230/1/60

COOLING CIRCUIT

111145 REV #4

B

N.O. TWO WAY

DRAIN VALVE

FILL VALVE

THREE WAY

OPTIONAL

OPTIONAL

208/1/60

COOLING CIRCUIT

111452 REV #4

B

PUMP MOTOR

230 VOLT

FLOAT

SWITCH

V

Y

W

H

W

B

BUCK-BOOST

40 VA. TRANSFORMER

B

I

Y

J

R

B

BL

BR

Y

Y

FIGURE 10 - Wiring

Diagrams for

Evaporative Cooling

Module

WARNING: Adjust ball valve only when power is disconnected

from the unit. Failure to do so can cause electrical shock, personal

injury or death.

Ball

Valve

FIGURE 11 - Disconnect

power; adjust the water

flow with the ball valve.

5.0 Adjust Water

Flow Over

Media

Model REC with

Pump and Float

Control System,

Option ECD2

CAUTION: Do not flood the media pads with extreme quantities of water for long periods as this

will cause premature breakdown of the media. An even flow from top to bottom of the media with

the least amount of water is all that is required to assure maximum efficiency and media life span.

More water does NOT provide more evaporation or more cooling.

Float and Pump Control System - Using the ball valve (FIGURE 11), located in the

middle of the length of hose running from the pump to the sprinkler pipe inlet, adjust

the valve handle to allow the flow to completely dampen the media pads from top to

bottom.

Operate the unit watching the water flow. After 15 minutes with the blower in operation,

the water should have completely dampened the pads but should not be flowing off the

entering side of the media. If water is flowing off the entering side of the media, turn the

system off, disconnect the power, and reduce the entering water flow.

AquaSaver Timed Metering Control System - NOTE: Water flow and pad wetting

time should be adjusted at maximum airflow and wet bulb depression to assure com-

plete wetting of the media at the extreme operating conditions.

In addition to adjusting water flow, the timing of the water on/off cycle can be adjusted.

Adjustments are correct when

1) the water rises from the holes in the sprinkler pipe

(See

FIGURE 12A) consistently along the entire pipe length, 2) the media pads wet

evenly after a few “ON” cycles (no dry spots or dry streaks), and

3) a slight amount of

excess water collects at the drain at the completion of the “ON” cycle.

1) AquaSaver Water Flow Adjustment - Using the ball valve illustrated in FIGURE

12B, adjust the water flow depending on the pad height. See FIGURE 12A.