0 mechanical (cont’d), 2 water flow controls and connections (cont’d) – Reznor REC (Evaporative Cooling) Unit Installation Manual User Manual

Page 6

Form I-REC, P/N 16021R3, Page 6

3.0 Mechanical

(cont’d)

3.2.3 Inlet Water and Drain Connections

Inlet Water - All Cooling Modules - Install a manual water shutoff upstream of the

inlet, at a convenient non-freezing location, to allow the water supply to be turned on

and off. If necessary, install a bleed line between the manual valve and the cooling

module inlet to allow drainage of the line between the shutoff valve and the cooling

module.

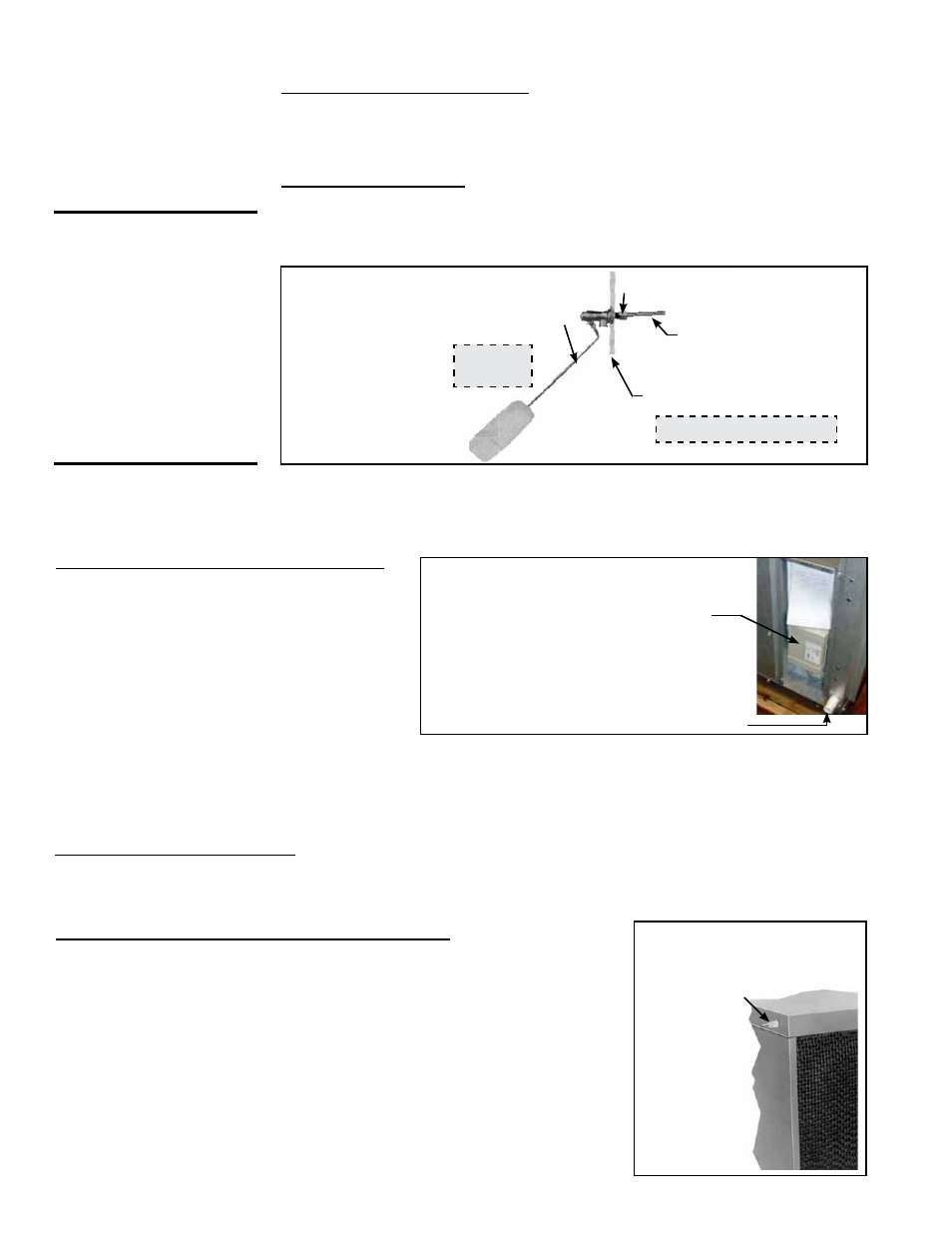

Pump and Float Controls - A float valve (FIGURE 6) maintains the appropriate water

level in the reservoir. Use a field-supplied 1/4” diameter tubing with a compression

nut and tubing ferrule to connect the fresh water supply to the inlet of the float valve.

Place nut and ferrule over tubing and insert tubing into the float valve stem. Tighten

nut securely.

FIGURE 6 -

Connect

Fresh Water

Supply to Inlet

of the Float

Valve (module

with float and

recirculating

pump controls)

Use 1/4” tubing for

fresh water supply.

Simulates Side Panel

Float Valve Rod

Field-supplied Compression

Nut and Tubing Ferrule

Outside the Cabinet

WARNING: Water

reservoir (outdoor

systems) must

be drained and

pump motor turned

off when outside

temperature falls

below 32°F (0°C). DO

NOT operate pump

without water in the

reservoir.

FIGURE 7 -

Electrical Box

(cover removed)

and Water

Connection on

Module with

AquaSaver

Controls

1/2” Supply

Line Connection

Microprocessor

Control Location -

AquaSaver System

AquaSaver Timed Metering Control System - If

the cooling module is equipped with a microproces-

sor timed metering system, connect a 1/2” water line

to the fitting on the side of the cooling module (

FIG-

URE 7).

Due to various water pressures and installation

conditions, the water supply line may bang abruptly

when the solenoid valve in the system closes. This

banging can be minimized by installing a water

hammer arrestor in the supply line. If installing an

An optional automatic fill and drain kit (Option CT1, CT2, or CT3) will automatically release supply water to the cooling

module when a call for cooling is made and will drain all water from the reservoir when the cooling switch is deactivated

or a cooling thermostat is satisfied. Fill and drain kits are field-installed. If installing an optional fill and drain kit, see

FIGURE 9, and follow the instructions that apply. Consult the wiring diagram for electrical connections.

3.2 Water Flow

Controls and

Connections

(cont’d)

Inside

Cabinet

optional water hammer arrestor, select an indoor (above 32°F/0°C) location, either horizontal or vertical, in line with

and as close to the solenoid valve as possible. Follow the manufacturer’s instructions to install and maintain the water

hammer arrestor.

A freeze protection kit is available for a module with a timed control system. It includes a two-way valve and is shipped

separately for field installation. See

FIGURE 9.

Drain and Overflow Connections - All cooling modules are equipped with an overflow and drain fitting. The fittings are

in the cabinet bottom and come complete with a locknut and a sealing gasket. Check these fittings for tightness before

installing the overflow and drain piping. The drain and overflow fitting will accommodate a 3/4” garden hose thread and

is tapped with a 1/2” female pipe thread for iron pipe.

Install bleed

line fitting

(fitting is

shipped in

the bottom

pan of the

evaporative

cooling

module).

FIGURE 8 - Bleed Line

Fitting (float and pump

controls)

Bleed Line Connection (pump and float controls only) – Using the 1/4” I.D. x

1/2” N.P.T. nylon bleed line fitting (shipped in evaporative cooler bottom pan; see

checklist in Paragraph 1.3), thread the fitting into the female adapter on the distri-

bution pipe. The hose barb will protrude from the side of the cabinet (See

FIGURE

8). Attach a field-supplied 1/4” I.D. hose to the barb and run to the nearest drain.

Discharging a quantity of water by “bleed off” will limit the concentration of unde-

sirable minerals in the water being circulated through the cooling module. Miner-

als build up because evaporation only releases “pure water vapor” causing the

concentration of contaminants in the water to increase as the evaporation process

continues to occur. The minerals accumulate on the media, in the water lines, on

the pump, and in the reservoir.

Adequate bleed off is important to maintaining an efficiently operating evaporative

cooling system.